Steel or plastic: a recipe for longevity of a washing machine

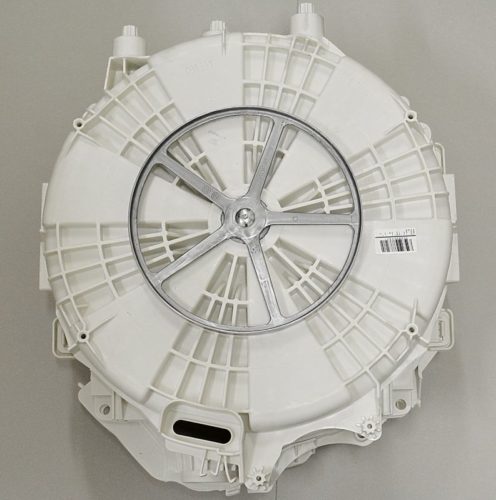

The tank is one of the key elements of the washing machine. Before choosing a washing machine model, it is recommended to carefully consider what it should be made of. Let's see what material is preferable for the washing machine tank, and why it copes better with its functional tasks.

Manufacturing technology

Durable and durable material - the key to successful operation of the washing unit, because in the work there are always serious loads and temperature changes. Foreign objects may damage or block the operation of the system.

Manufacturers use 3 material types for the manufacture of drum capacity:

- stainless steel;

- plastic;

- metal.

Stainless steel

Steel best of all copes with the constant interaction with water, and also differs special strength. It is very often used as a material for a washing machine tank.

The main advantages are:

- durability;

- reliability;

- strength;

- tank, made of stainless steel, will serve you for many years.

Despite this popularity, there are also disadvantages:

- High noise. This is caused by the inability to dampen vibration and noise. Many hostesses are unhappy with this phenomenon.

- High price. A quality steel product with conscientiously welded seams cannot have a low price.

- Devices with metal drum capacities consume more electricity, since metal is characterized by low thermal insulation.

Plastic

The second place in demand is occupied by products made of plastic and other polymers.

The advantages are:

- Low cost.

- Do not make noise. If you believe advertising, things will rub off completely silently. Perfectly cope with the absorption of noise and vibration.

- Less energy consumption, due to good thermal insulation. It takes less energy to heat water.

- Are not subject to corrosion, to influence of chemicals.

- Lightweight product and the device itself. When repairing it is much easier to remove than metal.

- Relative strength If you compare with stainless steel products, the plastic elements will lose due to its fragility. However, in this direction, ongoing developments are underway, and the composition of polymers for the manufacture of parts is improving, becoming stronger and more reliable. Service life can reach 30 years, which is significantly lower than that of stainless steel. However, this is enough, since the service life of the washing machine itself after this time will come to an end.

The only, but significant disadvantage is:

- Fragility. Damage may occur during transportation or if foreign bodies get between the drum and its tank. Breakage can be very serious, in which the use of technology becomes impossible.

Each washing machine manufacturer uses its own technology for the composition of the polymer.

Plastic differs in characteristics, has a low cost and high fragility. Due to additional impurities, the strength of the composition increases, and in some cases the productsmade of polymers, not too inferior in reliability elements of stainless steel and perfectly resist the aggressive effects of detergent chemicals.

Metal

Enameled metal tanks have long ceased to be made for a washing machine. They possess worthy reliability, and enamel protects against corrosion. The weight of such devices is very large. Products differ in durability, are not subject to splits when transporting and temperature differences, unlike plastic elements.

As a result of prolonged use, chips may appear from the impact of foreign objects in the drum. When damage enamel ceases to perform a protective function, begins to crumble, rust and collapse. The part is damaged by corrosion and starts to leak. In such cases, replacement of the spare part or the entire unit is required.

Now metal tanks are not produced, so if you have a similar problem with the old model of a washing machine, then it is better to change it to a more modern one.

Conclusion

At the choice of washing equipment should be given special attention to the material from which the tank unit is made.Its quality affects the durability of work. We met with the main types - it is stainless steel and polymers of different composition. The third type - enameled metal has become obsolete and gone. Manufacturers have abandoned the manufacture of elements for this technology in favor of more modern options.

The stainless steel is distinguished by its reliability and long service life, the main disadvantages are the high cost of high-quality steel, the high level of noise and vibration of the unit. Plastic is considered a good alternative to metal, is lightweight, copes with the suppression of noise and vibration background, is not susceptible to corrosion and chemical agents, and also has more affordable prices. Active work is underway on the composition of polymers, and today manufacturers can offer fairly durable products with a long service life. However, the problem of fragility is still not fully resolved.

When choosing washing machines with a plastic or metal tank, be sure to consider what material parts are made. Pay attention to its quality,After all, only durable products can ensure a long and uninterrupted operation of the entire system of the washing unit.

/rating_on.png)

/rating_off.png)