How to fix the washing machine control module

Modern washing machines are reliable and functional. The manufacturer does everything to make its product work for many years without interference. However, the control module of the washing machine fails more often than the owners of the unit would like. This happens for a variety of reasons, some of which are specifically stipulated by the manufacturer, and failure to comply with the conditions set by them leads to the termination of the warranty. Others may be caused by marriage. However, if the warranty period has expired, you can try to do an independent repair of the control board of the washing machine or to conduct a detailed diagnosis.

Content

How it works

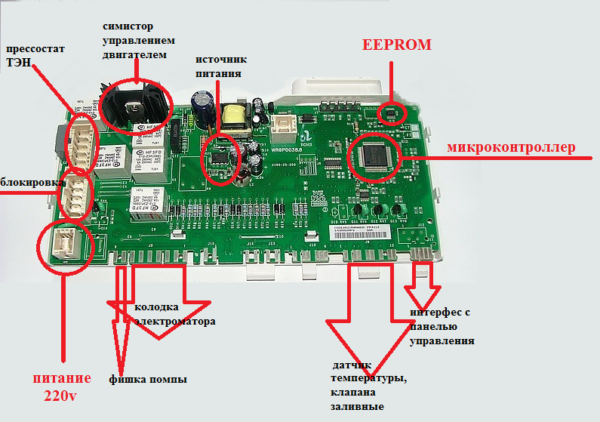

The control module is a computerized “heart” of the machine.Depending on the incoming signals from sensors and regulators, the control board activates this or that functionality. It is quite versatile. The manufacturer puts the same part on different brands of washers, marking them differently. For example, the most common models of the electronic module washing machine indesit marked as W105TX, WISL82. Depending on the generation of a specific model of a washer, the firmware of the central processor or the number of input and output signals may differ.

Control block:

- monitors temperature;

- sets the mode in which the motor operates;

- counts time periods of programs;

- responsible for starting up the drain pumps;

- provides control of water inlet pressure and flow shutter function;

- responsible for the lock operation.

The control signal is received through the terminal blocks or the corresponding contacts of the integrated bus. Determine exactly where the signal disappeared, you can. For this you will need specific control module circuit. For most washing machines such information is attached to the instructions. If there is no such data, you can easily find them on the Internet by marking, which the electronic board has.

Why does the control module fail?

There can be several reasons for the failure of the controlling controller. We list the main ones, with an indication of possible options for simple repairs:

- Manufacturing defects. It is determined visually - according to poor-quality contacts soldering, peeling tracks, flux fluxes in the installation zones of the central chip. If the machine is under warranty, you should not dismantle the module yourself. The electronic board is replaced in the conditions of the workshop under warranty. A factory defect appears very quickly, during the first weeks-months of operation.

- Power supply mismatch. Frequent shots, surges, exceeding the limit voltages can lead to failure of thin electronics. The parameters that must be observed are usually indicated in the instructions. Most often, a breakdown due to power deficiencies is easily identified during testing of the board for the washing machine. Service centers by all means try to recognize such a case of failure as non-warranty.

- Failure or improper operation of one or more sensors. This problem is often easily solved as - we will tell below.

- Water entering the electronics. It is worth noting that some of the manufacturers seek to completely eliminate this problem. For example, the control unit of individual models VEKO, LG, Samsung is filled with compound, sealed. Other manufacturers allow the ingress of fluid in the pause between washes. When you try to start a wet card protection is triggered, and control is blocked. For example, repair washing machine Indesit do it yourself may be reduced to wiping the module and thoroughly drying the board. Water can get as a result of emergency conditions, and during the carrying of the car, for example, when moving.

Other causes include excessive soot, the presence of conductive feces of domestic pests (cockroaches, mice), as well as the closure of insects or rodents through the body. Eliminate such troubles, if the protection system did not allow the accident, easy. Fee enough to clean.

How to identify problems in the control module

Signs that it is time to clean or repair the control board, and also to check the status of the sensors, can be several:

- The device does not turn on, the display shows an error.

- On some models, the panel LEDs flicker, blink, or light all at the same time.

- The machine refuses to wash, type or drain water, spin, heat, perform one of the operations included in the wash cycle.

- One of the programs is not running.

- The water is cold or overheated.

- Indicators blink randomly.

The reasons can be a variety of, for example, unexpected modes of operation of the engine - it either turns at full speed, or barely cranks up with an effort.

Some modern models have a self-test mode, which allows you to determine exactly which repair of electronic modules of washing machines is required.

Information on how to make an automatic check is not specified in the documentation. However, it can be found on the Internet in specialized forums. For example, some Ardo models are tested like this:

- water is drained and the tank is emptied;

- the mechanical program selector rotates vertically with the arrow;

- set to zero temperature.

After that, just press all the buttons on the control panel. at the same time. The machine will go into self-test mode. After its passage, an error will be displayed on the screen, according to which a fault is easily identified.

Self repair

The control device is removed quite simply.It is necessary, depending on the model, to remove the front panel or get to the installation site by dismantling the upper part of the machine. After this fee is charged.

In modern models provides protection "from the fool" - the terminals can not be put in the wrong position. However, when dismantling, it is worth looking carefully at what is connected to install the repaired module correctly. It is better to photograph the process. The fee is removed after removal fixing barswhich are usually fastened with screws or bolts with recessed heads.

Repairing an electronic control unit of a washing machine may require special skills. We'll have to test the parameters of the elements, check the integrity of the circuits.

Determine the need for specialist intervention is quite simple. The signs are as follows:

- On the board there are places of a changed color, burns, darkened tracks.

- The caps of the capacitors are clearly protruding or torn at the point of the cross cut.

- On the damping coils there are traces of burning paint.

- The installation site of the main processor is darkened, the legs of the chip have an unequal color.

If one of these signs is found, and there are no skills in working with a soldering station and a multimeter, then you should call a qualified specialist.

The control circuit of the washing machine

But a number of faults that cause failures in the management module can be eliminated independently. They are connected with sensor problems. For example:

- Failure of the installation program sensors. Occurs due to clogging and clogging of contact groups in the adjustment knob. Signs: the regulator rotates tightly, does not emit a distinct click. It is necessary to disassemble the handle and clean it.

- Accumulation of soot. Present in old washing machines. Visually easily identifiable: the power coils of the mains filter are covered with a layer of soot. It is carefully swept away with a dry cloth and a brush.

- Sensor failure hatch lock. It also occurs due to the layering of soapy remains, salting. The lock block must be cleaned.

- Launch failure after short-term scrolling of the motor, unstable turns. May be caused by a weak belt drive. The machine will need to disassemble and tighten the pulley.

- Electrical connections. Lack of grounding can lead to a “beating” of voltage, with the result that the control module blocks the operation of the device. Read how to ground the washing machine. here.

Another common problem that occurs with Indesit machines is unstable water pressure parameters. While the user is trying to solve the problem by repairing the central control unit of the washing machine, it’s just a matter of a squeezed hose, a broken gasket, or a dirty filter.

Conclusion

Repairing the control unit of a washing machine is a task requiring the intervention of qualified personnel.

Before removing the board, make sure that all sensors respond correctly. It is worthwhile to turn the knobs for setting the modes, check the lightness and clarity of the locking of the lock, make sure that the pressure and the water supply are normal.

Independent dismantling of the control board should be done only when the warranty has expired. If this happens, and other methods of dealing with faults do not help - the module is removed, in the absence of skills in repairing electronic equipment, it can be replaced entirely.

/rating_on.png)

/rating_off.png)