Repair the drain pump SMA do it yourself

Do it yourself repair the drain pump of your washing machine, without calling the master, it is quite possible. But first you will need to carry out a simple diagnosis of the device.

Content

Signs of a washing machine pump failure

If the machine works incorrectly, before disassembling the drain system, you need to make sure that the fault is located in this place. It can be identified by several signs:

- The water drain program has started, but pump down system does not work;

- heard during the drain loud noises and buzz;

- water is pumped out, but very slowly flows out;

- during the operation of the system, the machine can be turned off;

- the pump motor is buzzing but water does not flow out.

If one of these breakdowns is found, it is very likely that you will have to repair the pump of the washing machine.

Where is the pump

To extract the pumping system from the housing automatic washing machine (CMA) there are different ways, depending on the model of the unit. In models of Whirpool, Samsung, Ariston, Beko, LG, and others, missing bottom. Accordingly, you can remove the pump by tilting or laying the device on its side, and disconnecting the bottom panel (open the door or the hatch). After that, the screws that attach the snail to the front plate with the filter will be visible.

It's very simple in CMA Electrolux and Zanussi. Just open back cover typewriter, and you will see the node you want to disassemble. The most difficult access to the required parts in AGR, AEG, Bosch and Siemens. You can get to the pump only by removing front wall washing machine.

But before removing and repairing the drain pump in the washing machine, you must first check the reasons for which the water may not be pumped out:

- heavy blockage drain hose (you need to remove it, and good clean);

- drain filter clogged with debris (remove the filter from the cochlea and rinse well with water).

If the test and cleaning did not give results, after a test run of the rinse and drain mode, you need to remove the part and try to repair it.

Disassembly of the pump washing machine

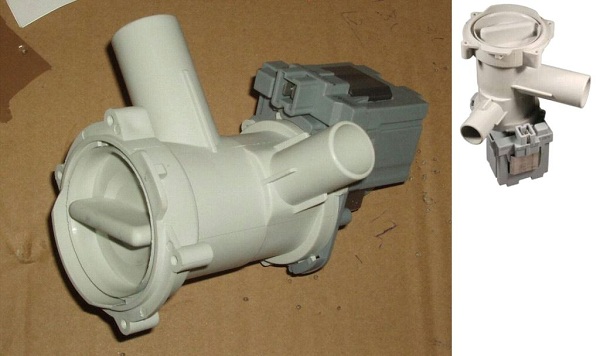

To disassemble the pump for troubleshooting, first disconnect it from snails. For this you need to unscrew the screws.

Some pump models have a different attachment to the cochlea. It is enough to turn it counterclockwise - and it will detach.

In the next troubleshooting step, check impeller. Although it can be seen without disassembling the entire structure: just pull out drain filter. Visually determine whether it is broken or not, perhaps. But to find out whether it scrolls on the shaft or is fixed will not work without complete disassembly.

The figure below shows a broken impeller, due to a regular coin falling into the system.

The impeller should not rotate easily. Normally, it rotates with some delays (jumps), due to the magnet rotating in the coil.

If the rotation is difficult, and visible interference in the form of various debris is not observed, then you have to disassemble the pump completely.

Internal pollution cleaning

To do this, using a screwdriver, pry the latch on the motor housing on both sides, and remove it from the coil.

There are still so-called “non-separable” motors, but even they can be “treated”.

After disconnecting the body with the blades from the coil, we will see a monolithic detail. It seems that the spider can not be removed. But there is a little trick.

- Take the usual building hair dryer, put on it the lowest temperature, put on gloves, and start to warm up the shank of the part (its long part). Do it with care.

- After a while, when the shank warms up well, pry crossbar Use a screwdriver and carefully remove it (together with the magnet) from the housing.

On the magnet and in the place where it was removed, there may be a lot of dirt. It is necessary to clean everything thoroughly, after which you can remove the magnet itself from the shaft. You will see bearingrequiring, respectively, cleaning and grease. Lubricate also the bearing on the bottom of the housing.

After that, insert everything in place, with a little pressure until it clicks. Sealing ring, located under the blades, should sit tightly in its place.

The figure below shows a dirty motor with a machine brand Indesit (Indesit).

In motors of this type, in addition to the above procedures, it may be necessary replacement of glands.

Cause in bearings

Contamination is not the only cause of device malfunction. At failure of bearings, during rotation of the shaft there is a beating. Due to the beating, the impeller begins to rub against the casing of the cochlea. This causes noise and unproductive pump operation, up to a complete stop.

This problem is solved replacing ball bearings, which can be purchased at specialized retail outlets or in the service center for home appliances.

If at the moment there is no opportunity to buy a new part, and the washing cannot wait, then the pump can temporarily prolong the life by shortening blades 2 millimeters with a sharp knife. But do not overdo it: if you cut more, system performance will drop.

After cleaning, replacement of bearings or seals, repair of a motor can be considered complete. Install the body with the blades in the coil and secure with latches. When complying with safety regulations, connect 220 V to two contacts, and check work devices. Making sure that the device is working normally, you can connect the cochlea and return the entire structure to the SMA housing.

As you could see, repairing a washing machine's pump with your own hands is not such an impossible task and can be done by everyone who has carefully read these recommendations.

/rating_on.png)

/rating_off.png)