We assemble a blender from scrap materials

Every person in an apartment, somewhere in the closet, has old, broken home appliances, electrical appliances, things, parts that seem to be no longer needed, but I feel sorry for throwing them out. And what if to show sharpness and try to collect something useful from them - for example, a blender? Consider how to make a blender with your own hands.

What is needed

In fact, the simplest hand (submersible) hoodp is not such a complicated device as it seems. In fact, this is just a motor with a button, speed mode switches and various nozzles for grinding products. That's all! Making such a device with your own hands is not at all difficult, with the availability of suitable parts and a minimum set of tools.

For this we need:

- A small electric motor.

- Container with plastic cover.

- Plastic bottle 0,5l.

- The switch with the wires.

- Connector for power supply.

- Ball pen.

- Power Supply.

Tool kit and materials:

- Stationery knife.

- Soldering iron.

- Super glue.

- File.

- Scissors for metal.

- Tin plate.

- Solder.

- Aluminum wire.

- Marker or marker.

Step-by-step instruction

From all of the above, the most difficult thing is to get an electric motor and a network adapter with suitable characteristics of current and voltage. Motor from toys, battery-powered, does not fit here, as it does not have sufficient power. But an electric motor from an old cassette tape recorder or a broken music center is fine.

Housing a blender in which all the details will be mounted, we will be served by a plastic bottle, which we will cut off from the side of the bottom so that the motor fits completely into it. Next, we solder two wires to the terminals of the electric motor and pass them into the neck of the bottle through the hole in its lid, done to install the switch.

Cut the wires of the motor so that they fit into the free space of the bottle after installing the switch in the cork hole, and solder their ends to the switch.We also wire the leads of the switch and power supply connector. Then we make a small hole in the bottle under the power supply connector and insert the connector into it. The plug with the switch is twisted on the neck.

Now it remains only to hermetically seal the resulting structure from the side of the electric motor, for which we use a plastic lid of suitable size suitable for some kind of container, having previously made an opening in it under the spindle of the electric motor. All loose parts fasten with instant glue for plastic.

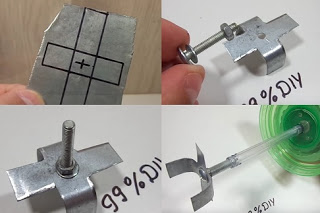

We proceed to the manufacture cutting nozzle. To do this, cut a cruciform cutting element from a tin plate and sharpen its edges with a file. In the center of the resulting nozzle we make a hole for its attachment to the motor shaft.

As shaft You can use any suitable-sized pin that can be securely fastened to the spindle of the electric motor. For example, a medium-sized screwdriver without a handle or a durable plastic ball-point case is perfect for this. After connecting all the manufactured parts together, our blender is ready for use.

Conclusion

As you already understood from the above, a corporate blender differs from a homemade one only convenience and reliability. He also has an electric motor control board for various operating modes and a fuse that protects the internal parts of the blender from voltage surges and overheating.

Often the cause of a blender breakage is precisely the failure of its fuse, and not something more serious.

But for the elimination of such a "malfunction" in the service with you can take money, as for a full repair. Therefore, it is better for yourself to at least a little understand the device of some simple household appliances than to overpay for services that are cheaper than air. It is also important to be able to take apart andrepair the blender do it yourself.

/rating_off.png)