We carry out repair grinders do it yourself

Modern coffee grinders are undoubtedly reliable and productive, but are designed for specific tasks. For example, a coffee grinder may need to be repaired if sugar is crushed in it instead of coffee beans. Other models, especially those manufactured by Bork and Bosch, suffer from moisture penetration into the motor shaft area. But in any case, if the engine is not burned, you can fix the device with your own hands.

Disassembly technology

Most coffee grinders have a fairly transparent disassembly algorithm. There are two types of devices:

- knife grinders;

- millstones mill

The latter have a separate algorithm for disassembling the grinding mechanism.The answer to the question of how to completely disassemble a mill type grinder depends from a specific model devices. The general scheme is the same. The tapered knives of the mill are mounted on the drive shaft with three or four bolts. Unscrew them easily. However, when reassembling it is necessary to carefully ensure that the heads are fully inserted into the seats. If you assemble the mill device without tightening the bolts, you can burn the grinder, or you can constantly find fine metal dust in the grinding because the protruding heads of the fasteners protrude into the zone of movement of the grinding mechanism.

Cases of coffee grinders are easy to disassemble. You need to unscrew a couple of self-tapping screws, which are often located on the bottom plane, the bottom of the machine. Access to them can be both open and protected by the legs of the device.

A separate group of coffee grinders keeps on snaps. For example, the Bosch MKM 6000 model, the Soviet ZMM apparatus, the burr ECMU 50 and EKMZ 125. Here, the lower part of the body is removed using thin probes or screwdrivers with which the latches are bent.

To pull the engine to inspect the condition of the bearings and shaft, it is required dismantle knives. They are removed in different ways.The most common type of connection is threaded. It uses the principle of self-engagement. If the knife moves clockwise, then the left thread is cut at the joint. If counterclockwise, right. To dismantle the knife, you need to place the screwdriver slot in the corresponding slot of the shaft, and then turn the knife unit clockwise or counterclockwise, depending on the thread.

It is necessary to act carefully when dismantling the knife. The groove on the shaft is shallow, the metal is soft, so the screwdriver needs to be placed tightly, press it down and apply force gradually when unscrewing the knife.

Over time, the attachment zone becomes clogged with the remnants of grinding, it is caught by oxides. Therefore it is recommended to apply grease WD-40to remove dirt and easily unscrew the knife block. In the case when the clamping nut has a tapered thread and is made of bronze, it is possible to slightly heat the joint zone using a soldering iron.

Further actions depend from coffee grinder model. Disassemble the device must be carefully, tracking the limiters, removing the structural elements of the grooves. Most often, after removing the knife block, you need to do quite a bit:

- Unscrew the locking plastic nut that holds the grinding cup. It is not possible to lose the felt anti-dust gasket attached to the fixing nut.

- Remove the axle steel washer.

- Remove the interlocking plate by gently pressing it down and out of the housing's restrictive slots.

Disassembly of most models of coffee grinders (for example, Saeco GROUP 700, Bosch MKM 6000) ends with the removal of antisplash washers and the dismantling of the power wire, switch. In the course of detailed disassembly, it can be established that, for example, the washer has burst or is completely unsuitable (the felt pad has been salted, compacted).

Replace the damaged item is easy. For this you should know coffee grinder detailing, the Internet has data on most common devices. After that, you can go to the market, to a specialized store or service center, having on hand exactly the name and number of the necessary part.

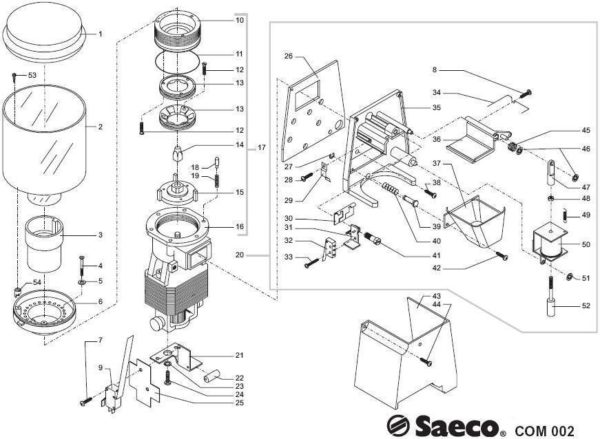

Saeco coffee grinder detailing example

Common problems and solutions

To repair an engine or determine its performance, a multimeter and knowledge of where to measure winding resistances are needed. Therefore, we will touch only relatively easy troubles, which can be eliminated even with the minimum skills to work with the tool.

Power cable failure and lockout failure

The broken power cable is visible to the naked eye. But if the place of inflection is close to the body, you can detect a breakdown by simply moving the wire. If the device began to show signs of life - then you have to change the cable.

Blocking failure occurs due to clogging pressure mechanism (located on the groove line of the cover) or lack of pressure of the inner plate. Checking the lock is simple - click on the protruding plastic element with a thin screwdriver. If at a certain position the grinder comes to life, you need to disassemble it and eliminate the pollution.

The device does not start

There may be several reasons: from a cable break inside (to eliminate such a problem, soldering iron skills will be needed) to engine failure. In this case, verification will require special knowledge. In this case, the repair is economically inefficient, it requires rewinding or buying a new engine, it is often easier and cheaper to buy a new grinder.

The knife rotates unevenly, turns sharply decrease with an increase in the mass of grinding

One of the reasons - a partial failure of the engine, burnout of one of the windings. Repair can be a problem. Diagnosis, rewind or costly replacement will be required.

When working there is a smell of burning, the straining sound of the engine

The most common cause is contamination and oxidation of bearings or sleeve sleeves. This problem is very often observed in Bosch 6000 series coffee grinders. To eliminate contamination, you need to carefully disassemble the device, check the ease of sliding of all blocks, lubricate the bearings. The Bosch 6000 models do the following:

- a sliding sleeve is removed from the shaft (upper part);

- the shaft is treated with alcohol;

- with obvious signs of corrosion, it is removed with the help of special tools or WD 40.

Shaft can be processed sandpaper-null, you need to act carefully. The procedure shown in the following video does not apply to the category of frequently used. With diligence and constant maintenance of this kind, you can change the gap in the sliding sleeve, which will lead to malfunctions of various kinds.

Conclusion

Self-repair of the grinder can be carried out periodically. Maintenance procedures include lubrication and decontamination. To prevent accidents, do not operate the grinder in modes not recommended by the manufacturer. For example, grind sugar into powder, grind herbal seasonings, process large masses of grinding. Each equipment has its own rules of operation and if you do not violate them, the device will work for a long time and without fail.

/rating_on.png)

/rating_off.png)