How to make a spotter out of the microwave

Spotter translates as a spotter, but the garage masters know that this is a specific resistance welding machine for body work. It differs from ordinary spot welding in that the impulse is formed in a very short time, and metal does not have time to heat up. Many craftsmen have mastered the manufacture of such an original device, so that with its help to align dents on car bodies. We will explain in detail how you can design a spotter from a microwave, which has worked for a long time in the kitchen.

Content

Manufacturing method

One of the most important knots of a future homemade product is transformer, which is already extremely difficult to find or purchase. Therefore, many do the spotter with their own hands from the microwave, in which the ready device is already present. For reliable operation of the contact welding machine, a pair of transformers from the old microwaves are taken, the secondary winding is removed and the new one is wound, using a wire with a cross section of at least 50 square meters. mm

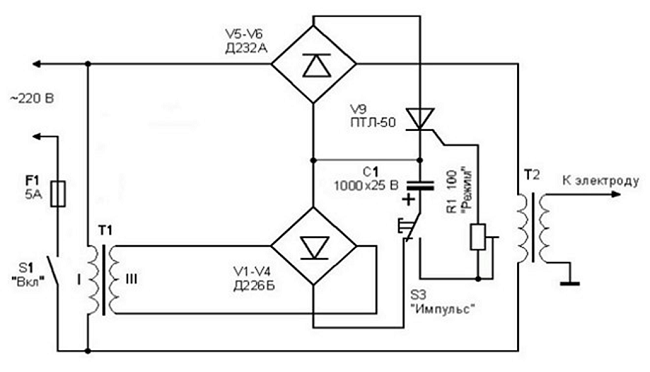

The spotter circuitry consists of the following components:

- main transformer;

- diode bridge;

- variable resistor;

- thyristor.

The simplest schematic diagram of the spotter is shown in the figure.

Housing

To ensure the safe operation of a spot-welding machine made of microwaves, all its components must be placed in a separate housing, which will reliably protect them from possible mechanical damage and environmental influences. For this purpose, some use old furnace.

Handles should be attached to the body - they will be very useful when moving the device.

All parts are fixed rigidly on the sheet. dielectric materialto avoid interference. They must be placed evenly: massive transformers are fixed in the middle to balance the weight.Some craftsmen attach small wheels to the bottom to transport the device during operation.

Spotter body

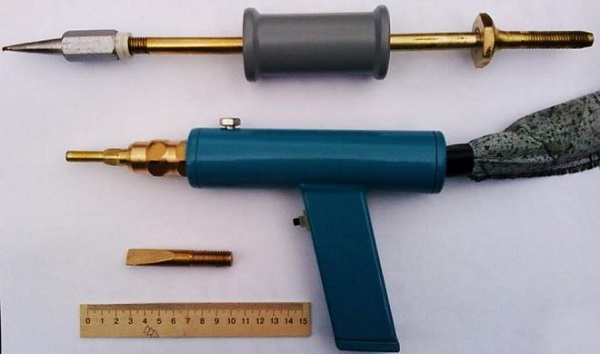

After fixing all the components, begin manufacturing devices, without which the normal operation of the spotter is impossible:

- electrical cables;

- a gun to conveniently fix the electrode for welding;

- adapted for the subsequent extrusion of the bent segments of the metal body, called the aliener.

The necessary drawings, calculations of the section and the length of the cables to reduce the loss of electricity to a minimum, can be found on the Internet.

Holder, electrodes

Pistol bodywork professionals are advised to make from getinaksa - a special laminated material used for insulation, because it has a paper base that is impregnated with epoxy or phenolic resin. Two blanks of identical size are cut from the sheet, then the button for switching on is installed, the bracket where the electrode is attached. It all connects, fastens. The outer surface is polished for easy handling.

Electrode made from copper rod round section or tube made of bronze, which are convenient for pulling the supply wires inside them. From the end where the working part will be located, a slot is made where the washer is inserted, the tube is pre-flattened with a hammer.

Inoppuller

To make a reverse hammer, you can use an ordinary mounting gunit is only necessary to make minor modifications to its design. Home masters, who have decided on their own to make the device of resistance welding of available tools, can find the exact method of manufacturing each tool on YouTube.

It is important

Specialists working with car bodies of different brands advise to remember the main points before proceeding to the independent production of the spotter.

- The handle is most often made of a standard glue gun.

- Connecting cable cover specific insulating layerwhich can be deformed by heating the wires.

- In the manufacture of the spotter, its design must be clearly thought out in advance to the smallest detail.

- Spot welding during operation should work properly, regardless of its size and money spent on its production.

The technique of how to make a spotter from the parts and components at hand differs little when you make it from a broken welding machine or an old microwave oven - the main thing is to show ingenuity and special care when working with high voltage transformers.

Glue gun

Product advantages

The main advantages of a homemade apparatus of spot welding include such characteristics.

- Quite high performance. With it, you can quickly weld special fixtures anywhere in the body for the subsequent extraction of dents on the metal.

- Enough ease of use. Compared with the large dimensions of industrial devices for resistance welding and their large mass, homemade products are more mobile. When working, there are practically no sparks - a source of fire danger when carrying out such work in a garage where there are fuel and lubricants and fuel reserves. The metal remains cold, so the use of protective glasses, gloves and special clothes of the welder is no longer necessary.

- Supreme quality level. Such welding practically does not leave traces on the metal in the form of scale, slags, which contribute to the occurrence of corrosion in the course of further operation, does not spoil the presentation of the parts.

- Large economy. Washers for fastening can be used repeatedly, they are not exposed to melting, thus, there is a saving of consumable material.

The positive qualities of homemade devices for aligning dents lead to the fact that many amateur motorists are beginning to make similar devices for self-repair of their cars, in order to really save the family budget.

/rating_on.png)