How to safely use the grinder

This hand tool has become indispensable in various fields, especially in construction and metalworking. With it, increases productivity. The appearance of a large number of different attachments has led to a significant expansion of the functionality of the device.

But how to use the grinder correctly, far from all workers who regularly apply it in their activities know. It should be noted that failure to observe the elementary rules for safe handling of the angle grinder is very dangerous. dangerous injuriessometimes fatal. Avoiding this will help compliance with operating instructions. An important place in preventing injuries is the serviceability of the tool, the use of suitable personal protective equipment, as well as the right choice of discs for cutting and grinding various materials.

Content

Operations that can be performed using the grinder

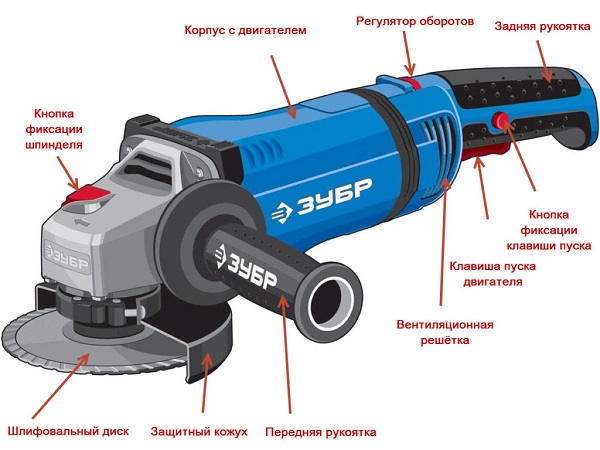

Bulgarian is a multifunctional tool. The driving mechanism in it is an electric motor, which, through a gearbox, transmits movement to the shaft with a replaceable attachment fixed to it. General view of the device is presented in the photo below.

On the market are models with different capacity and design:

- household;

LBM (Bulgarian) FT-1318

- professional;

Professional large Bulgarian 230mm Stern AG230B

- with or without handles.

Powerful devices are powered from a three-phase voltage of 380 V, and household ones from a single-phase network of 220 V. There are also low-power battery models.

The angle grinder (angle grinder) can do with different materials the following main types of work:

- cutting;

- grinding;

- polishing.

If you fix the grinder motionless, you can sharpen different tools on the wheel: cutters, drills, knives, etc.

LBM is designed to work with such materials:

- concrete;

- metal;

- a tree;

- glass;

- ceramic tiles;

- a stone;

- brick;

- plastic.

Bulgarians became widespread both in everyday life and in industrial conditions. This is due to their wide functionality due to the following factors:

- a large selection various nozzles from different materials to perform various operations;

- opportunity fixed fixation using special fasteners;

- presence in some models extra pens and several speed modes.

At the same time, it is necessary to constantly remember that only special discs are used to process each material.

What is the danger of an angle grinder?

LBM is a traumatic tool. It is caused by the following reasons:

- high speed of rotation of the working nozzle - it exceeds 10 000 rpm;

- the openness (lack of protection of the enclosure) of most of the disk;

- the possibility of breaking the abrasive disc into fragments of different sizes, which at the same time fly apart around the sides with considerable speed;

- frequent lack of the possibility of proper organization of the workplace;

- formation when cutting metal (or other material) or grinding fine particles.

When the disc is jammed, which occurs even because of its slight skew, the grinder is almost impossible to hold, especially a powerful tool. This is caused by a high speed of rotation of the nozzle. Therefore, beginners are encouraged to work with low-power models, complete with disks with a diameter of 115-125 mm. The latter should be without the slightest defects that can lead to their sudden destruction and the tearing of the angle grinders from the hands with uncertain consequences.

General safety rules

To reduce the possibility of injury when working with a grinder, this tool should be handled correctly. It is necessary to observe the following terms of use:

- Must use personal protective equipment. Operator health should be in good condition.

- Before work, it is necessary to check the correctness and reliability of fastening the casing so that it does not fall off in the process, and the sparks do not fly off to the operator.

- Use only whole discs without defects (cracks, chips, cracks) and strictly for the purpose for processing a particular material.

- Protective shield must be located between the operator and the circle so that there is protection when the latter is destroyed.

- Before starting work, you need to test the tool at idle for about 1 minute: uniform rotation at maximum speed, no vibration.

- Before use, inspect any attachments to determine their suitability for use.

- It is necessary to protect asbestos or a normal damp cloth from sparks with objects that can ignite: oily rags, fuel and lubricants, paper, solvents, ropes.

- Constantly required reliably fix working nozzlesso that they do not fly away.

- If it is possible to regulate the rotational speed, it is necessary to set the revolutions recommended for cutting or grinding the working material.

- It is very neat to cut the tree, because contact with the bitch can cause the tool to jerk from the hands.

- It is forbidden to install the nozzle from the circular saw due to the fact that they are designed for a different speed of rotation of the spindle.

- Tool need hold with two hands.

- Starting to do the work, you need to remove all unnecessary and make sure that no objects other than the workpiece are missing on the cutting plane.

- Take regular breaks at work.

- When jamming the workpiece, turn off the tool immediately.

- Should maintain a stable (balanced) body position.

- Power cord must be kept away from the rotating part in order not to cut it or cause a short circuit.

- Only after a complete stop of the circle is it allowed to let the instrument out of my hands.

- At transitions on a workplace it is necessary to disconnect the grinder, also it needs to be done at switching off of the feeding tension.

- It is necessary to cut only at full speed.

The stated safety measures have been developed by manufacturers of angle grinders, as well as special organizations (services) engaged in labor protection activities.

To ensure the safety of work is better to buy not the cheapest, high-quality materials from reliable manufacturers.

The person working as a grinder must be adequate and be in a balanced psychological state.

Used protective equipment

When working with an angle grinder, the user should use the following personal protective equipment:

- face shield or glasses that cover the eyes from all sides;

- gloves from dense fabric or skin;

- special shoes (whole, stable) and work clothes;

- respirator, which will provide protection against penetration of small particles into the respiratory organs when cutting concrete, glass or ceramic tile, brick, porcelain stoneware, foam block, stone and other dusty materials.

To work with the grinder the use of protective equipment is mandatory. It helps to work more safely.

How can not work grinder

Safety when using angle grinders should be in the first place. According to it is prohibited:

- produce working manipulation without PPE;

- works in light clothing that does not completely cover the body (arms, legs);

- use a machine that is not equipped with a casing to protect against sparks;

- without testing the tool at idle to start using it;

- work defect disc or unsuitable for the material;

- located in the cutting plane;

- apply pressure to the tool;

- work so that the direction of rotation of the circle was towards the operator;

- perform work without taking breaks, because the hands get tired, and it is difficult to hold the grinder tightly;

- so that the workpiece is not fixed (for example, in a vice or clamps);

- sharpen metal parts with the side of the disk;

- perform cutting blanks, the thickness of which exceeds half the radius of the used circle;

- finding unauthorized persons in the work area;

- touch the nozzles until they cool down, because they get very hot when cutting and grinding against friction;

- when deepening the circle in the workpiece include a tool;

- grind thin discs;

- use nozzles of larger diameter than the angle grinder;

- arrange the workpiece so that when cutting occurs clamping a circle (the cut should be on a break, but not on squeezing).

Safe use of the saw in the grinder is ensured by the fact that its replacement is carried out only when the device is disconnected from the network.

Which way can be cut with a grinder

Before you start cutting material, you should understandwhich way the Bulgarian should turn: sparks from oneself or oneself. There is no unequivocal answer among users, they work in both ways. If the nozzle rotates counterclockwise, the sparks (as well as the broken circle) fly in the direction opposite to the operator, but the recoil of the tool during jamming will occur on the user. In the second case, everything happens the other way around. According to safety, it is believed that the correct rotation - when the sparks fly toward the operator, because when wedged, the tool jerk will be in the opposite direction.

In any case, manufacturers recommend that the movement of the angle grinder and the rotation of its circle be directed one way. This greatly reduces the possibility that the disc will come out of the slot during the work process. But with this method, the markings on the material often hide the flying sparks.

Change the rotation of the nozzle by moving the handle and the cover to the other side. This is the easiest option (if you can do this). A more complicated way is to make changes in the electrical circuit of the device. But this does not always help.

The important point is to ensure the correct position of the working tool: it is necessary that the cutting line is located on the side of the operator. Then, if suddenly there will be a jamming of a nozzle, the Bulgarian will pull aside.

When cutting, it is necessary that the working plane does not change, and also there is no distortion. Discs must be used in accordance with the material being processed. So, concrete, tile, stone is cut with the help of circles of different diameters, having a diamond coating.

The nuances of cutting some materials

At cutting concrete comply with the following recommendations:

- Before work, check for the presence of pipes embedded in concrete, fittings, electrical wiring (with a metal detector or devices for searching for wiring);

- to reduce dustiness, the working surface is moistened with water (for example, from a spray bottle or with a brush);

- periodically cool the cutting element with air or water.

In the absence of a tile cutter with a grinder, tile is also cut. Experts cut circles even in tile. Stone with tiles cut in two ways:

- wet (moisten the working area with water);

- dry (without moisture).

In the first version, cooling is improved, but dirt remains, and in the second, a lot of dust is emitted.The wet method is used for large volumes of upcoming work, and the dry method - for one-time cutting.

Any material should be cut smoothly in order to immerse the disk into it with a slight pressure, practically only under the action of its own angle grinder. This is necessary to prevent distortion of the disk and reduce the likelihood of its jamming. If the process slows down, then you need to replace the nozzle with a new one.

Use the grinder should be in accordance with the instructions for use and safety regulations. The working part must rotate in the direction of movement of the tool. Before starting the process, it is imperative to turn on the device at idle. In this case, the vibration, heating of the grinder, as well as other sounds from it should be absent. Circles must be used without damage. The most dangerous factor is the back kick. To prevent it, you need to avoid jamming the circles, cutting the materials on the break.

/rating_off.png)