Cutting of a tile and porcelain tile the Bulgarian

Each master who is engaged in facing of walls with a ceramic tile, knows that it is impossible to lay it without cutting. This is true both when facing walls, and when laying porcelain stoneware on the floor. But not everyone knows that you can use an ordinary grinder (LBM) for trimming. Consider how to properly and without chipping to perform this operation.

Content

What kind of discs are cutting tiles?

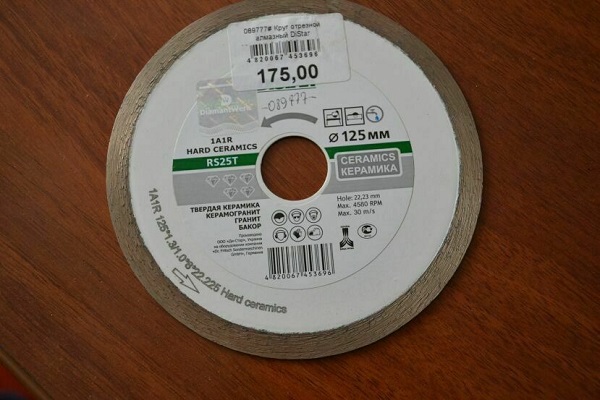

For cutting ceramics, special discs are needed, which can be stone or metal with a diamond coating. Stone is rarely used, as it is rather thick and quickly grind off, and during work it is very dusty. The cost of stone disks is several times less than metal ones, but experts prefer to work last.

Metal discs can be:

- solid;

- segmented.

Ceramics processing is preferable to produce solid discs. When working with such disks there is a time limit: they can not continuously cut more than 1-1.5 minutes. Then it should be allowed to cool while the grinder is idling.

Segmented designed for cutting pavers, porcelain stoneware, natural stone or concrete.

Segments are designed to better cool the tool during operation.

Cutting ceramics

To cut a tile with a grinder, you must master the three directions of the cut.

Straight cut

Mastering it is not difficult, at the same time, the cutting line is clean and without chipping. When performing work, the tile is securely fixed on a flat surface, marked out with a pencil or felt-tip pen. The cut off part must hang freely from the table. Cutting tool at right angles to the workpiece. Carefully, without jerking, slowly drive the angle grinder along the marked line.Move the tool towards yourself so that the marked line is visible.

45 angle0

It is often necessary to dock, and this involves cutting the material at an angle of forty-five degrees. This angle can be obtained only with a large workout. But you can use this technique: first, cut the workpiece in a straight line, and then carefully with a disk, sandpaper or grinding stone process the edge at the desired angle.

Figured cutout

Often there is a need to cut round hole in tile. To do the job correctly with the help of LBM is possible with certain skills. To do this, mark the hole on the workpiece and circle the line with a felt-tip pen, mark the center of the circle. Begin to cut at a small angle, slowly, on the inside of the line, gradually passing around the entire circumference. Then cut the sector, remove them in turn, if necessary, cutting the ceramics. Finally process the edges with a file, getting a smooth circle. This treatment is called sukhorez.

Such openings, as a rule, cut under the sewer or ventilation.

When performing shape workpiece processing is easiest to perform rectangular cutouts. In order for the cuts to be smooth, without chipping, it is necessary to regularly change the cutting wheel. If segmented discs are used, chips are necessarily appearing on the cut line.

How to get rid of dust when cutting tiles

Cutting tiles with a grinder is not very difficult, but there is a lot of dust. There are techniques that can reduce dust formation. Experts for this use special tile cutters, but buying them for a one-time job is impractical because of the high cost. Therefore, when processing the details of the master act differently. First, a layer of glaze is cut through - it is almost dusty, the main dust appears when a layer of baked clay is processed. Then it remains to carefully break the ceramic tiles and process the edges with abrasive material.

A common way to get rid of dust - wetting the workpiece. To do this, constantly pour water into the work area with a diamond wheel. It is necessary after each pass of the tool to fill the seam with water or install a special device for supplying water to the working area. This device is attached directly to the protective cover of the grinder.As a result, the workpiece is processed without dust.

Cutting porcelain stoneware

When performing repairs, it is not only walls that are revetted. On the floors in the bathroom and the toilet is laid ceramic granite tiles - artificial material that replaces the granite and marble. Its cost is several times less natural, but the parameters of hardness and abrasion of ceramic granite exceeds them. Recently, he received widespread distribution. It can also be cut using angle grinders.

For this you need to know the basic methods of processing material in the home.

- It is necessary to choose the right cutting tool. It should be written for what it is used: porcelain, hard ceramics, etc.

- To reduce chips, choose a disc with a continuous application of the cutting edge. Thickness should be minimal.

- Choose a cutting wheel, which has a large height of the diamond coating.

- Bulgarian should have speed control.

After selecting the tool, prepare the workplace and begin to cut the porcelain tile grinder. To do this, you must perform such sequential actions.

- Place the material on a flat surface, placing it under thin foam or similar material.

- Secure the tile to the surface with clamps.

- To reduce chipping, glue masking tape and mark up, on which it is necessary to cut off the excess part.

- Prepare a vacuum cleaner to remove dust.

- It is necessary to cut from the front side by moving the grinding machine away from you.

- It is recommended not to cut along the marked line, but a little apart. This is done for the subsequent polishing of the end face of porcelain stoneware in order to remove irregularities and chips.

Following these simple recommendations, you can do it yourself with a high quality cut of floor tiles.

Cutting pavers using angle grinders

Having a private house, there is a need for laying paving slabs or paving stones, which must be cut to size. To do this, they also apply a universal device that is available in almost every home - an angle grinder.

The processing of paving stones has its own characteristics, but basically it is performed in the same way as cutting porcelain stoneware. The main differences are that the work is performed outdoors. Material processing should be made on a separate site: The resulting dust settles on the paved pavement and can spoil its appearance.If this happens, you should immediately sweep it with a stiff brush.

To cut the pavement, choose a diamond disc for processing concrete. The angle grinder should be held at a right angle to the workpiece, and the diamond wheel should be moved exactly along the marking line. It is necessary to cut the tile to a depth of a little more than half, and then just break it and trim it.

Safety when cutting tiles grinder

To cut the tile grinder, paving or porcelain tiles was safe, you should observe the following safety guidelines.

- All operations must be performed. in workwear, eliminating the possibility of falling into the rotating parts.

- Be sure to use safety glasses.

- It is recommended to use ear plugs

- Tools, carrying and other devices must be in good condition.

- Persons under the age of 18 and trained in the operation of cutting equipment must be allowed to work.

- If used wet processing, make sure that the grinder does not fall into the water. Otherwise it may cause electric shock.

- Do not process workpieces at maximum speed; work indoors with good ventilation.

In order to preserve life and health, one should strictly observe these conditions. And then you can finish the repair on time and enjoy its results for many years.

/rating_off.png)