Varieties of wood cutters for the drill

Drill is a multifunctional and useful tool familiar to every home craftsman. With the help of special nozzles, not only an excellent compactor of the concrete composition, but also many other devices can come out of it. For example, in the market you can find such a nozzle as a mill on a tree for a drill. Thanks to her, various types of woodwork are becoming available.

Content

Application at work

This tool will turn your power tool into an effective mechanism for wood processing:

- slot grooves of complex shape;

- grinding corners and edges;

- processing of complex elements.

And this is not a complete list of opportunities, drop-down with a working nozzle on the drill. Properly selected for certain tasks detail will help to perform not only the rough work, but also the final touches.

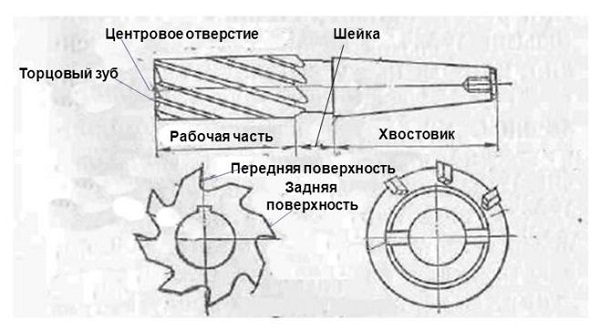

Design

As a rule, all types of cutters are manufactured on the same principle. The main details of the nozzle are:

- shank;

- the working part is the point for wood brushing and other works (depending on the shape of the sharpening).

It is the shape of the edge that is responsible for the purpose of the tool.. It is honed in a special way on a high-precision machine. The procedure is quite complicated, because the smallest failure can spoil the work. Details of the machine must be accurately synchronized with each other, the only way to achieve the necessary sharpening parameters.

For the manufacture of tips used special types of steel, selected depending on the upcoming work and the parameters of the treated wood.

Types of wood cutters

Except in special cases, the mill is divided into two types.

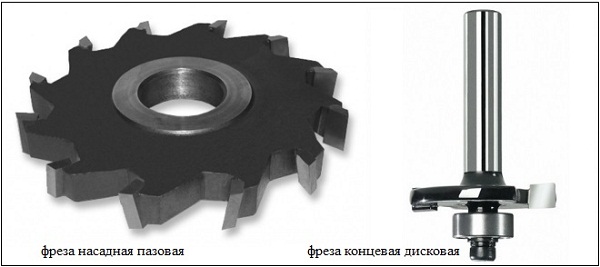

- MountedThe diameter of their landing tail is thirty-two millimeters. Most often used for installation in a stationary milling machine.

- Terminalthey are also called finger ones. The tail of such nozzles has a diameter of from eight to twelve millimeters. They can be installed both on the machine and on the drill.

The milling cutter used as a supplement on a drill may be of the second type only. Such parts easily replace the profile machine and even the jigsaw. By means of a mill such materials are processed:

- natural wood;

- plywood;

- MDF;

- Chipboard.

The most wear-resistant are plywood nozzles. Like the jigsaw, it has cutting plates, so it is not sharpened when used. Such tools are made of durable alloy, thereby increasing the period of use.

Selection options

There are several distinctive features that distinguish the cutters from each other. All of them are divided into several categories and are designed to work with wood. Distinctive features are:

- the size;

- cutting edge shape;

- sharpening angle;

- material of which the cutting part is made;

- appointment.

Knowing these parameters, you can easily find the necessary nozzle.

Purpose of different types

To process the wood, there are many tools. Various machines, jigsaw, grinders - this is due to the different specifications of materials and the complexity of the procedure. Among tips for a drill distinguish the following types.

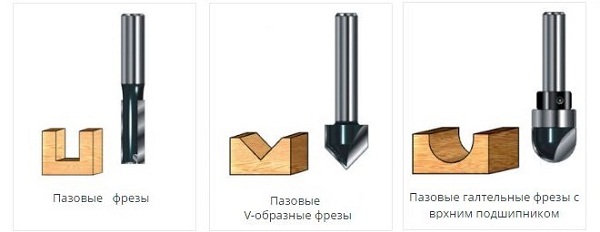

- Masting - it is used when rounding corners and grinding them.

- V-shaped used for the same cut and create a groove on a wooden canvas. You can also use to create an inscription or pattern. In addition, the milling cutter performs edge processing.

- Disk drives indispensable when creating grooves, grooves and grooves of any depth.

- Faltsevye similar to disk, but provide greater freedom of action. They are often used to cut a groove under the glass.

- Fillet - to create semicircular grooves on the ends of the workpiece, equipped with a special support bearing. Used in the manufacture of furniture slats.

- Spike - the nozzle equipped with the cutting edge made in the form of the return thorn. It is used for making dovetail grooves. Perfect for making hidden connections.

Mill on a groove grooved tree

- Cylindrical - with the help of such a nozzle a flat surface of wooden parts is processed. In the manufacture of the part is equipped with straight or spiral blades.

Of course, such attachments are not always able to replace a full-fledged machine or the same jigsaw, but they are quite capable of satisfying a one-time necessity.

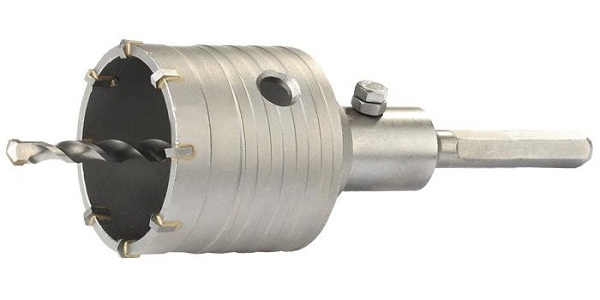

Other nozzles

Drill can work not only with wood, but also with concrete.For example, a special crown allows you to make wide holes in the solid composition. Application concrete crowns may be required during construction or repair work, so the ability to use a familiar drill will be most welcome.

Crown for concrete drill

Such tools are used if necessary to build a channel for communications:

- electrical wiring;

- gas pipes;

- telephone and internet cables.

There is a special type of diamond-coated crowns - they effectively cope with concrete and other hard surfaces.

As you can see, a simple nozzle can turn an ordinary drill into a multifunctional machine. The ease of use and compactness of the device make it more attractive than complex and expensive specialized equipment.

/rating_off.png)