How to make a router, planer and jointer

Frazer is an indispensable tool when carrying out all kinds of woodwork and is actively used by professionals. But if he is needed by a home craftsman to carry out one-off work, then it makes sense to try to make it with your own hands from improvised tools. Of course, a homemade mill on wood, made, for example, from a drill or a grinder, is not able to completely replace the standard tool. But some simple operations that do not require high purity processing, it is quite acceptable to perform such a unit.

Content

Making a router bit from a drill

Milling cutter from a drill with his own hands is made easily and quickly, because this tool already has a cartridge in which you can clamp the cutter shank. But since the drill develops small revolutions, around 3000 rpm, it will not be possible to achieve good quality machining of the part.

For comparison: the milling machine can reach speeds of up to 30,000 rpm.

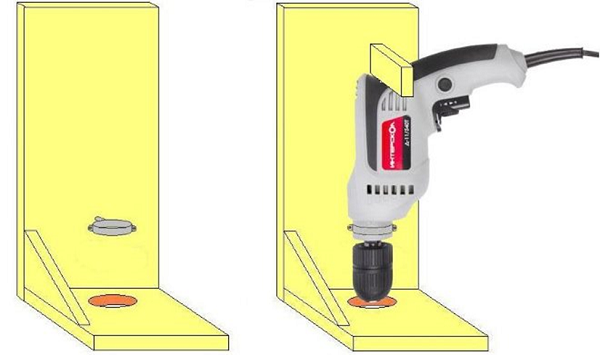

Ideal for mounting the drill vertical drillwhich can be purchased at the power tool shop. It will only be necessary to change the equipment, and the homemade mill is ready.

Also a similar stand can be to make of chipboardas shown in the following figures.

For example, such a homemade device can be no worse than a finished router to make a groove in a plate made of laminated chipboard under the T-shaped edge of PVC.

How to make a mill from the grinder

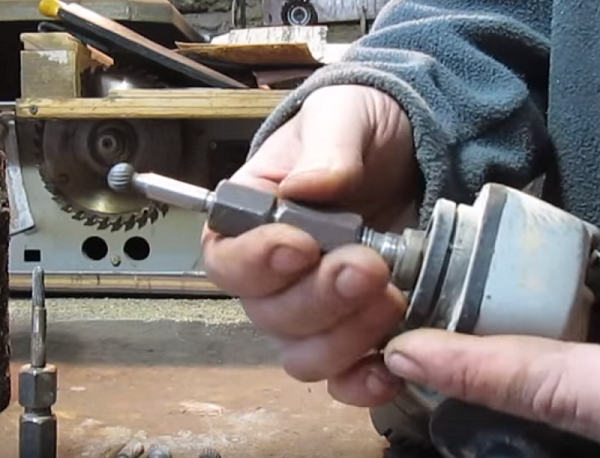

It is no secret that the angle grinder is often used for grinding, polishing and milling various surfaces with disk and cup nozzles. But if you screw the collet onto the spindle of the aggregate, you get a grinder from a grinder that can work not only with disc cutters, but also with any tooling that has cylindrical shanks.

If in a collet to clamp a mill from a hard-alloy material, then the mill on metal will turn out.

Also, to make a milling cutter, on the spindle of the grinder, you can also fix the usual cam chuck from the drill.

The photo above shows a device for the grinder, which turns it into a manual milling machine. How to make fit, you can understand from this video.

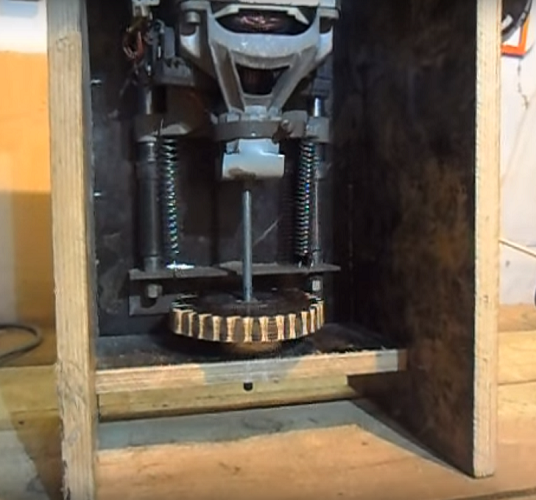

Milling cutter from the engine of the washing machine

Very often, craftsmen make various machines from the engine of a washing machine: turning on wood, drilling, sharpening, circular, as well as stationary milling machines. To make the latter, you first need to make the table in the manner described above. Further, the motor shaft must install collet for clamping cutters.

Since it cannot be fixed to the motor shaft without an adapter, it will have to be ordered from the turner.

Also need to do lifting gear for convenient adjustment of the instrument overhang. It is made of two pipes, performing the role of racks on which the engine is fixed, and a threaded stud.

The stud with one end enters a nut fixed to the bottom of the table, and the other rests against the bottom of the motor. The swivel wheel is rigidly fixed on the stud, with the help of which the height is adjusted.

To prevent the dust from getting to the motor when the machine is running, a small piece of foam rubber can be placed on top of the engine.

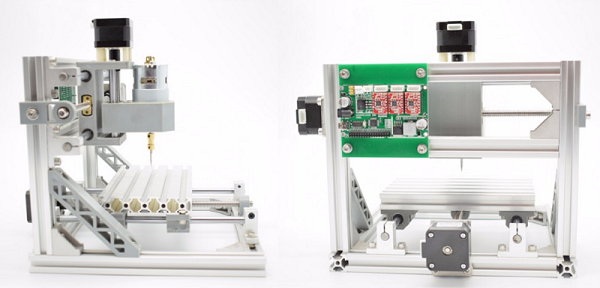

CNC router

The numerical control unit (CNC) is mainly used for engraving and figure carving. It is controlled by a computer, so that on the blanks you can cut very complex patterns with high accuracy. In China, you can buy ready-made mini-machines with CNC for the manufacture of souvenirs at a price of about 10,000 rubles.

Of course, you can purchase all the parts for the machine and assemble the CNC milling cutter yourself. But if you look at the cost of all components, it will be much cheaper to purchase a finished product with already configured software.

Reysmus and jointer from a milling cutter

The purpose of the gauge is the calibration of wood blanks in one size in thickness.

On the basis of the router it is also possible to make some kind of this unit.

A gauge can be made from a frezer with your own hands from a pair of guides mounted on a flat surface and the platform on which the milling machine is attached. The detail which needs to be leveled on thickness is fixed on a table, under the platform with the unit.On the router, the desired outreach is first set, after which the entire surface of the part is processed.

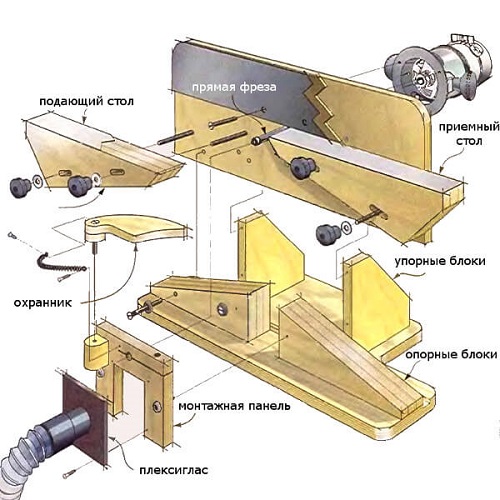

Using a milling machine as a drive, you can make and mini jointer for processing small-sized blanks. The figure below shows what parts a portable jointing machine consists of.

You can also make stationary jointer from the router for processing long workpieces. How this is done, you can learn from the following video.

/rating_off.png)