The nuances of the application and selection of the impact drill

Modern descendants of the ancient bend went through a long evolution and turned into a reliable, multifunctional electric tool. In addition to drilling holes in various materials, the impact drill is capable of performing the work of a mixer, setting the smallest revolutions, you can turn it into a screwdriver, and with special need, the tool quickly becomes a grinding machine.

Content

Design features

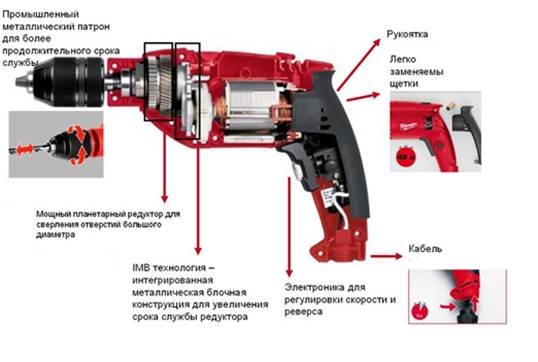

The principle of the product - two ratchet opposite each other repel as the motor spindle rotates and give the rotating drill another translational movement. The design of the electric impact drill gearbox consists of a large gear and two wave washers (ratchets).When the tool turns on, the rotation of the rotor of the engine is transmitted to the spindle, then to the large gear, to which the first ratchet is rigidly fixed. Its wavy surface slides over the similar surface of the second ratchet attached to the gearbox housing. As a result of their collisions shock occurs on the drill. Below is a diagram of the device of the impact drill, where:

- gear gear;

- two ratchets;

- spindle;

- bearing.

For high-quality work and a significant increase in service life, wavy surfaces are lubricated with a special lubricant, such as litol.

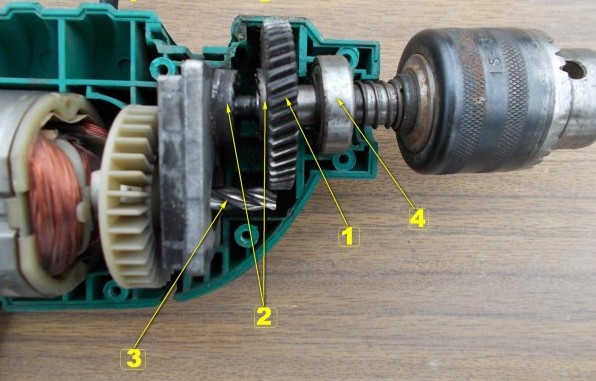

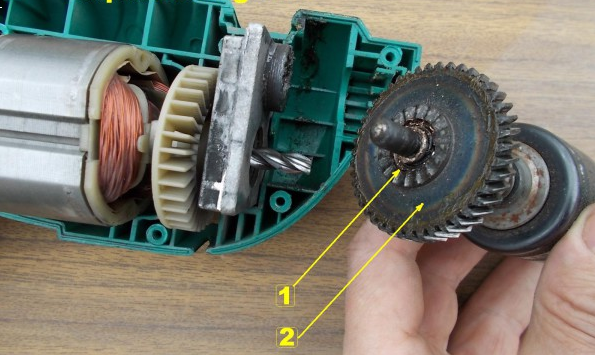

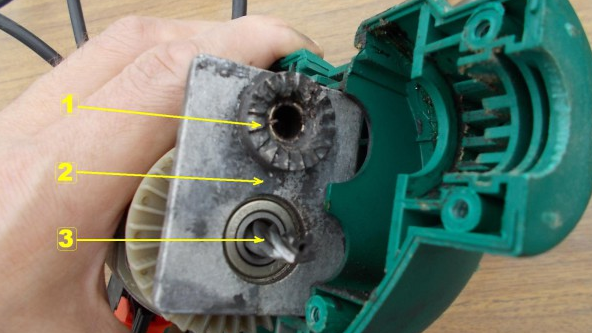

In the photos you can clearly see what elements it consists of. hammer drill mechanism. Left photo: 1 - ratchet, 2 - gearbox housing, 3 - spindle; on the right: 1 - the second ratchet; 2 - large gear gear.

Many users purchase such a tool for home use. Using beat drills and including a percussion mechanism, you can make holes in concrete or masonry, and during repair use a drill instead of a powerful mixer for mixing wallpaper glue and mixes for laying tiles. In particular demand rechargeable hammer drillbecause it works without a wired connection, it is better to use it as a screwdriver. Even in the disconnected state, it is ready to work if its battery is charged.

Tool types

Electric drills are considered the most sought-after tool, because they can be used for various purposes. Specialists divide them into two main groups:

- for use in everyday life.

- professional appointment.

The first option is used briefly during the repair or disposable work on the interior design: fixing shelves and baguettes or kitchen equipment with wall cabinets. The second is for daily long-term operation at construction sites.

Maximum power professional tool - 1550 W, for household use, the popularity of drills with power up to 600 watts. Drills with a capacity of up to 300 watts belong to the lightweight tool and do not have an additional second handle, this is how they differ from a two-speed household impact drill. They are used in hard-to-reach places, where a more powerful tool cannot be reached due to its size.

The cordless percussion drill has a low weight, maximum torque for soft metals up to 24 N.m, for solid - up to 55 N.m, can drill holes with a diameter of up to 13 mm.Such an autonomous tool belongs to the class of two-speed impact drills.

All models of modern impact drills have speed adjustment, therefore they are unified: they can drill holes at high revs or tighten screws and screws with the smallest rotation of the spindle. Many equipped with a reverse for easy removal of the drill from the hole after drilling, unscrewing the screws and screws in the screwdriver mode.

Many people ask: what is the need for a long metal part sticking out of a special holder on a removable extension handle? This is the depth control knob. With it, you can accurately gauge the size of the future deepening of the drill, it plays the role of an improvised stopper during the drilling process.

Drill with removable extension handle

Benefits of using

Work of any hammer drill differs in certain advantages from simple analogs of the electric tool.

- Drilling holes in highly durable materials. For example, for this purpose, drills for concrete are used, equipped with special pointed nozzles - such a cutting tool is used for a hammer drill when rotary and translational movements are used.

- If the drill has a reverse and speed control, then it is used when loosening screws, screws and screws when dismantling various equipment.

- Special nozzles turn the drill into a grinding machine, and with a slight refinement and in mini grinder.

Technical nuances of choice

When choosing a hammer drill, you need to know exactly for what specific purposes you are purchasing it. The cordless percussion drill is considered an indispensable assistant for working in a country cottage: it does not need a connection, you can use it in outbuildings where there is no electrical network or in the garden. When you buy a product with a cord, its optimal length should be at least 5 meters - this will allow you to work without fear that the tool will be disconnected from the network due to the extreme tension of the cord.

Reversible drill it is very convenient when using it instead of a screwdriver, and even when drilling concrete, a reverse brick helps to remove the drill bit from the hole during a break in work to cool the cutting tool. It is worth paying attention to torque value: the higher it is, the easier it is for the motor to work, respectively, drilling will be fast and of high quality.

Many models have additional features available:

- speed control is made by pressing the start button - the stronger it is, the faster the rotation;

- a processor that allows you to choose the best option speed;

- the button is fixed in a certain position so that your hands do not get tired.

All the nuances need to be recognized when purchasing, and not when active exploitation has begun - this will allow the user to choose the exact tool that he needs so much, without overpaying for excessive power.

Every user should know that for home use it is necessary to buy a hammer drill with a metal body: this option will work much longer compared to a similar tool dressed in plastic.

The higher the power, the faster and easier to drill a hole with perfect edges in the material of any hardness, but this increases the weight of the tool and its dimensions. The impact drill with a capacity of up to 400 W has a mass of 1.4 kg, and with a power of 1000 W, its weight almost doubles - such an increase in mass occurs due to an increase in the dimensions of the main gearbox. Some manufacturers leave the compactness of the tool due to the installation of new powerful electric motors, small in size,but with a high torque gearbox - in this situation the price increases quite strongly.

What is the difference between household and professional tools

Sometimes it is quite difficult to make the right choice: there are different models for home and professional activities on the shelves. Impact drills for domestic use have a more beautiful design and various improvements that protect the ergonomics of the tool.

It is easy and pleasant to work with such a tool, but many home craftsmen are primarily interested in technical characteristics, and not in appearance.

The main difference between the drill for the house is that it works from time to time, and not continuously. Models for technical use are more power and size, since they are designed for huge and daily loads. Therefore, they are distinguished by a modified design: the gearbox is enclosed in a steel casing made of hardened steel, and better cooling of internal parts is used.

Electric motor has dust protectionAfter all, a professional tool is used in any setting: draughty interior rooms of buildings under construction, or dusty basements where electrical wiring and other improvements need to be made.

Professional impact drill is a very powerful, high-quality tool with increased reliability of all parts, it is designed for long-term operation in any, the most adverse conditions.

In order to choose an excellent and reliable tool for home or professional activity, it is necessary to adhere to the principle that the best impact drill has the highest technical performance in its class. The main thing - do not forget to thoroughly check the hammer drill before paying, you should not save on quality, because you will get a tool for long-term use.

/rating_off.png)