Homemade vibrating plate and vibrolath

Very often during the construction of various objects it is necessary to tamp the base of the bulk materials under them, and after pouring - the concrete solution. For these purposes, in practice, widely used method of vibration compaction. It lies in the fact that vibrations from the operating equipment are transmitted to the rammed layer. As a result of the process, the particles of the material being compacted move as closely as possible to each other, and the air is squeezed out of the concrete, due to which after its solidification into the monolith it acquires its calculated strength due to the absence of voids.

In order to effectively tamp down loose soil, gravel, gravel or sand use vibrating plates. Flooded concrete mortar level, compacting it with vibrating rails. But it makes sense to buy such equipment only with regular and large volumes of construction work.For rare household use, you can easily make a vibrating plate with your own hands, and making a vibrating rail is even easier. To independently implement the project, you should first familiarize yourself with the structures of the units.

Content

Options for the manufacture of basic elements

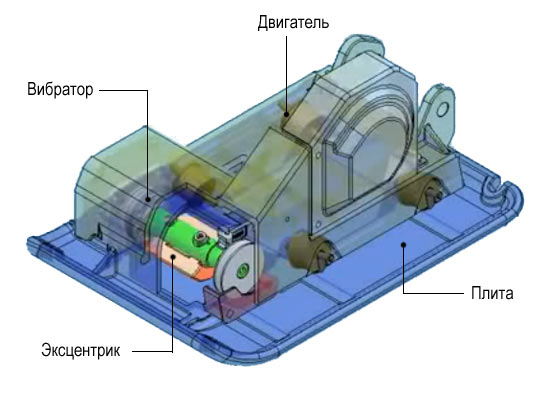

The design of the plate is quite simple. It consists of four main nodes:

- engine;

- plates;

- frames;

- vibrator.

Engine

As a drive for homemade vibrotool you can use:

- electric motor;

- gasoline or diesel internal combustion engine (ICE).

The electric motor for the vibrating plate, which is planned to be assembled, is recommended to choose a power from 1.5 to 2 kW. The speed of rotation should be from 4000 to 5000 revolutions per minute. If the power of the electric motor is less than the specified value, then this will affect the performance of the created unit in the direction of lowering it.

The electric motor is the most expensive part of a homemade installation.For home use, it is better to buy single-phase modifications of electric motors, for example, in the composition of IV-99E or IV-98E vibrators, operating from a voltage of 220 V. An electric motor can also be removed from old unused equipment, for example, from a drilling machine. It is necessary only to match the power and speed.

If you equip a homemade technique with an electric motor, then in order to increase the safety of work, it is recommended to install a separate protection, for example, a differential automatic machine or residual current device (RCD).

Diftautomat, in addition to preventing the operator from electric shock, also turns off the equipment when overloaded or short-circuited in the circuit.

Self-made vibrating plate can also be equipped internal combustion engine. If you buy it, it is recommended to give preference to single-cylinder three-stroke engines from the company Honda. ICE from a chainsaw or motoblock also fit.

Plate and frame

From the engine, the movement of the vibrator is transmitted by a belt - it is installed on the pulleys. By changing the dimensions of the latter (diameter), you can set the required speed of the vibrator. Suitable for belt drive car belt. The plate is made of steel or cast iron sheet with a thickness of 8-10 mm. Above it is the rest of the design. To make the frame, use metal corners 5 to 5 cm or larger.

Vibrator

Vibrator for vibrating plates can be purchased factory made or make yourself in various ways. One of the options for homemade vibration will be discussed in the next paragraph.

Additional structural elements

Lightweight (up to 75 kg), universal (75-90 kg) and moderate (from 90 to 140 kg weight) models of technology without the possibility of remote control are equipped with metal pipe handles. With their help, the operator sets the direction of motion.

For ease of transportation units also equip wheels. They can be removed if necessary. To move a homemade plate, you can take the wheels, for example, from the old car.

Vibrating plate assembly algorithm

To make a vibrating plate for soil compaction yourself, you will need the following materials and parts:

- steel sheet size 50 to 80 cm with a thickness of not less than 8 mm;

- areal vibrator with an electric motor, for example, IV-98E;

- 2 pieces of channel 45 cm long;

- fasteners: bolts M10 and M12 with nuts, washers;

- shock absorbers;

- 1.5 m of metal pipe (diameter 20-25 mm).

From the tools you will need:

- welding machine;

- hammer;

- Bulgarian with cutting wheels;

- electric drill with a set of drills for metal;

- spanners;

- Roulette, marker or chalk.

Work on the assembly of homemade equipment is recommended to be done, having protected his eyes with glasses, and his hands with gloves.

The self-made vibrating plate with the electric motor gathers in such sequence.

- The grinder makes cuts about 5 mm deep (so that the metal can be bent) at both ends of the steel sheet. 10 cm recede from the front edge, and 5 cm from the rear.

- At an angle of about 20-30 degrees, the edges are bent with a hammer, after which the bend is boiled by welding.

- Two channels are welded parallel to the curved edges at a distance of about 5-10 cm from the center line of the workpiece.

- In the center of them establish a vibrator, the legs of which make marks for fasteners.

- Drill holes in channels with an electric drill.

- Mount the vibrator, attaching it with bolts with nuts and washers.

- Attach shock-absorbing pillows to the slab.

- Bend the tube, giving it a U-shape to make a handle.

- Bolt holes are drilled at the edges.

- Through metal corners and shock absorbers attach the handle to the sole.

- Connect the power cable and install the start protection device.

- Check the performance of the created unit.

The mass of the assembled plate is about 60 kg. To be convenient to transport it, welded to the stove piece of pipewhich will serve as the axle wheels.

A more complicated variant of creating a vibrating plate involves the use of a separate engine, for example, from a motor-block. In this case, to assemble the vibration equipment, you will need a homemade or factory vibrator. The rotation of the motor will be transmitted to it with the help of a belt, dressed on pulleys.

The diameter of the latter must be chosen so that the eccentric of the vibrator rotates at a frequency of approximately 180 revolutions per minute.

The whole process of assembling the plate is presented in the photo below.

After painting, the final mechanism will look like in the photo below.

If necessary, you can increase the mass of self-made vibrating plates. This is done by additional welding of metal sheets or rods of reinforcement.The self-created vibrotool is quite capable of competing with factory analogues.

Methods for making vibrolaths

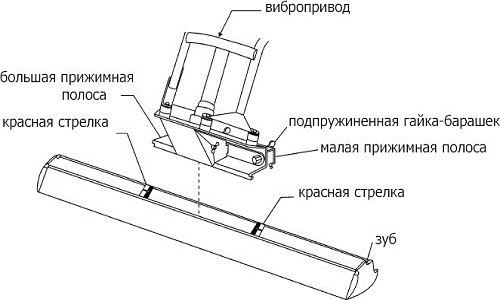

The self-made vibrolath is the tool having the simple device. It consists of the following main structural elements:

- drive;

- slats (frames);

- control knobs.

At home, vibrotools are made in two ways:

- in the form of a mop;

- in the form of a rigid frame.

The drive equipment is a gasoline or electric motor. For home use, it is better to use an electric motor as the basis of the mechanism, because it can be used without problems. indoors, for example, with floor screed.

The engine can be removed from old power tools or from unused household appliances.

A 1.5 kW electric motor is enough to compact a layer of concrete mortar with a thickness of 200 mm, as well as level it. If you use an engine with a large value of this parameter, it will, in most cases, lead to unnecessary power consumption. Only when it is really planned to perform a large volume of construction operations in the living conditions associated with the tamping of concrete,You can take the motor more power. This will be a reasonable step in terms of performance, efficiency and safety of work.

If it is necessary to work, mainly on the street or in well-ventilated areas, it is quite possible to replace the electric motor internal combustion engineFor example, from chainsaws or mowers. Only use it to start, in conjunction with the clutch.

To make a frame, suitable steel channel or flat board. For home use, it is enough to equip home-made vibration equipment with a rail up to 3 m long. Orientation when choosing this parameter is generally necessary for the size of the object you want to build.

Algorithm assembly vibrolyski

To implement the simplest versions of the drawings are not needed. As a drive unit fit:

- Sander;

- Bulgarian;

- electric drill or screwdriver.

This power tool does not even need to disassemble. Assembling a homemade unit will take little time.

You will also need the following working tools and materials:

- smooth, polished board 0.5 m long, about 3 cm thick, 25 cm wide;

- self-tapping screws;

- punched tape;

- bar 5 by 5 cm in length 1-1.5 (2 pieces) to make a handle.

Rake from the electric drill in the form of a mop going in this sequence:

- the surface of the board (if it is not ground) is made smooth using a planer and emery paper;

- to it from above exactly in the center, using punched tape and screws, fixed laid along an electric drill;

- on both sides of the drill, retreating a few centimeters, attach the handle at an angle, cutting off the ends of the bars obliquely;

- the nozzle is fixed in the power tool cartridge, the center of gravity of which is shifted, for example, a clamping key, a curved drill bit or a piece of reinforcement;

- Include the unit in the network and check its performance.

Drill chuck should rotate around an axis coinciding with the central longitudinal line of the board. Vibration occurs through the use of nozzles with offset center of gravity.

Vibrolath from grinder, grinder or screwdriver is done in a similar way. Only after compacting and leveling the concrete, the power tool will need to be well cleaned of the solution so that it can be used in the future. Work homemade vibration tool on the basis of the grinding machine shown in the video below.

If it is required to compact and level the concrete with a layer up to 10 cm, then a vibrating rake from a deep vibrator is suitable. It is made as follows:

- cut out plywood sheet of rectangular shape (with a length of about 70x50 cm);

- punched tape or with clamps attached to it mace, while the vibrator itself serves as a kind of pen.

In order for the rail to move freely, the working surface of the plywood rectangle is better to be hammered with a tin bent at the edges.

In the considered variants, in order to fix the power tool to the base, other fasteners can also be used. There is open space for engineering creativity.

Manufacturing universal vibrolyski

In order to build a powerful enough vibration equipment, you will need (besides a 220 V electric motor) more such materials:

- steel channel (up to 120 mm wide) or profile metal pipe;

- iron or aluminum corners;

- piece of tin about 500 to 200 mm;

- bolts with nuts or screws;

- nozzle on the shaft (coupling) with an offset center of gravity;

- start button;

- power cable;

- starting device;

- reinforcing bars or metal tubes.

From the tools you will need:

- electric drill with metal drills;

- welding machine and electrodes to it;

- spanners;

- hammer;

- pliers;

- angle grinder;

- Roulette with a marker.

The rake is assembled according to this algorithm:

- mark on the channel (or pipe) the desired length;

- cut with the help of the grinder excess from the workpiece;

- centrally welded through a certain period, using a welding machine, two corners for mounting an electric motor on them;

- drill holes in them;

- mount the electric motor on the corners, attaching it with the help of bolts with nuts;

- the shaft is filled with a nozzle that will create vibrations;

- around the self-made vibrator of tin make a protective cover;

- connect the power cable through a button (instead of it, you can simply do with a plug under the socket) to the electric motor;

- welded handles of reinforcement or metal pipe;

- launch the device into operation.

The distance between the corners depends on the design and dimensions of the electric motor. For greater convenience in the use of homemade equipment not its handles should be put on pieces of rubber hose or wrap them with insulating tape.

To automate the unit and make it more secure, it is recommended to install a starter for starting the electric motor and a differential automatic.

Vibrolath collected on the basis of the motor from the washing machine, shown in the video below.

It is possible to make a vibrolath for concrete with your own hands or a vibrating plate for tamping gravel, gravel, sand in different ways. Home craftsmen have come up with many options, differing in their design, used to create them with materials. To perform a one-time job, you can assemble a simplest device for vibrating ramming. If it is necessary to regularly compact concrete solution or bulk materials in everyday life, then it will be necessary to produce more complex and productive vibration equipment. In all cases, the created structure must comply with the elementary requirements of safety in order to avoid injury during its operation.

/rating_off.png)