How to make a homemade emery for your own workshop

Often there is a situation when it is necessary to sharpen a tool or sharpen knives. To perform these works, a grinding machine is best suited - it is also called sharpening or sandpaper. This is the simplest power tool, which consists of electric motor and abrasive wheel. The trading network sells many options that differ from each other in price and manufacturer, but are designed to perform one function - sharpening the cutting tool. Do not be in a hurry to purchase a factory-made electric wand: any home craftsman is able to make it with his own hands with the necessary parts.

Content

Motor selection

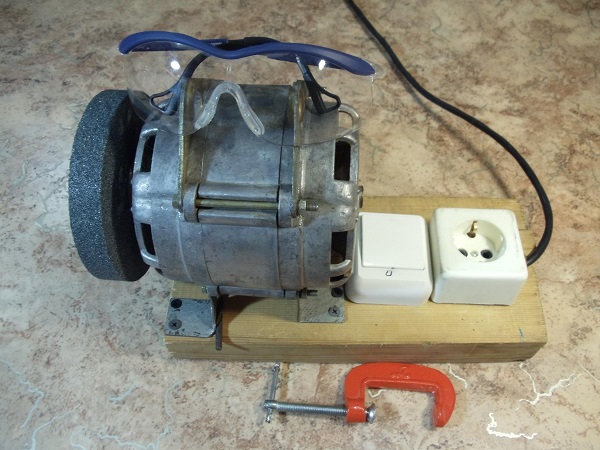

To make emery yourself, first of all you need to choose a suitable electric motor. Most often it is a motor from an old-style washing machine, for example, Baby, it is perfectly suited for this purpose.. Such a motor meets certain requirements: its power is within 100-200 W, and the number of revolutions does not exceed 1500 revolutions per minute. If the rotational speed is higher, there will be a danger of destruction of the abrasive wheel.

High engine speeds are needed for polishing parts, and they are not suitable for sharpening.

To make a homemade emery, you can apply any another electric motor. It must meet certain parameters.

- Rotation of the shaft should be minimal. Motors that are no more than 1,000 revolutions per minute are best suited.

- Motor power should be in the range from 100 W to 1 kW. The most commonly used motors with a power of 400 watts.

- It is desirable that he had paws for attachment.

- Best suited single-phase or asynchronous motor, designed for the inclusion of 220 volts in the network.

The algorithm for assembling sandpaper from the engine from the washing machine Baby

First of all we do the frame of the future mechanism. It can be made of thick wooden boards, wood-based panels, suitable plastic, but a thick metal plate is best suited. An electric motor is fixed to it with the help of brackets, angles or collars. The connection of the electric motor with the stone occurs through the flange.

Homemade Flyanets

Flange manufacturing - one of the technically difficult operations when assembling homemade emery. It is done, as a rule, using a lathe. To do this, measure the diameter of the output shaft and abrasive wheel, which will be used in a grinding machine. However, if there is no lathe at hand, you can do without it. In the video below you can see how to make a sandpaper flange from the material at hand:

Fixing flange on the shaft with a nut with a bolt and a washer. In this case, the direction of rotation of the shaft must be taken into account: the thread on the nut must be in the opposite direction.

This is done for safety reasons, so that during operation the nut does not unwind under the action of the vibration of the machine, which is fraught with flying off the abrasive wheel and injuries.

Finally, it remains to mount the electric torch on a permanent place and bring electricity. Emery out of the engine Baby is ready.

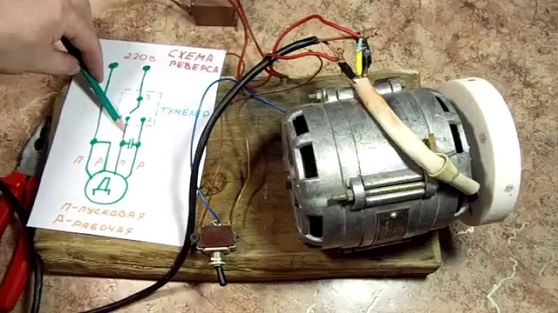

In the case of using an engine dismantled from an automatic washing machine, you can make a sharpening machine in the same way, the only difference is in the connection of electricity. The motor from an ordinary washing machine has four wires: two are connected to the working winding, and the other two to the starting one. To determine the working winding, it is enough to measure the resistance of both. The resistance of the starting winding is 30 Ohms, and the worker has only 12 Ohms. The engines of modern cars have six conclusions, two of which are the output of a tachometer with a resistance of 70 Ohms. Find them will not be easy. These wires must be insulated.

Wiring diagram consists in the following: both windings are connected in parallel and connected to the network, and a button is connected to the break of the starting winding. To do this, you can take the trigger or adjust the button from the doorbell.

How to adapt the drill and grinder for electric

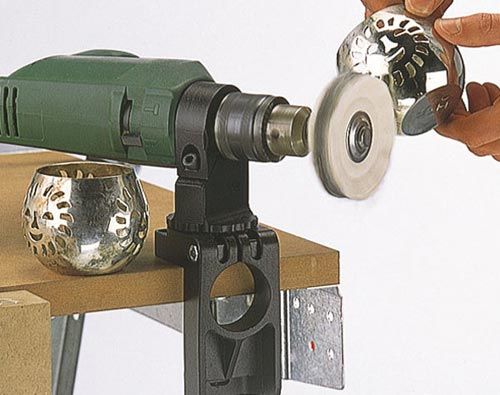

You can make sandpaper not only from a suitable electric motor that is available.To do this, you can adapt a power tool - it can be an electric drill or a screwdriver.

The latter is worse for these purposes: it has insufficient power and a small battery life.

The making of a sharpener from a drill begins with purchase nozzles.

It is fixed grinding wheel, and then clamped into the cartridge. It remains to secure it on a fixed base with the help of a special fixture, which can be bought in a shop selling power tools. With the help of such electrostatic, you can fix the ax, sharpen a kitchen knife or fill the drill.

In case of emergency, sharpened can be made. from the Bulgarian. It does not require the purchase of special tools and mandrels necessary for attaching emery. It is only necessary to fix it in a horizontal position on a massive base, install a standard cutting or grinding wheel, and the sharpener is ready for work.

Mini sharpening machine

Electric sharpener is necessary, if the master engaged in modeling: When working, it is often necessary to undermine small parts. Big sharpener is not suitable for fine work,so often do mini sandpaper with their own hands. The assembly algorithm is as follows:

- take the engine from the hard drive of a computer or children's toys;

- the tension bushing spokes from the moped soldered to the axis of the engine;

- a small grinding wheel is screwed with a screw and a washer to the shaft;

- connect the power supply;

- fix the device on the frame, and emery ready.

Often for these purposes use electric motors from a faulty sewing machine. The advantage of this machine is that the engine has a speed regulator, and this expands the capabilities of the device. It can be successfully applied and like a polisher.

Safety when working with a homemade device

When making power tools yourself, you should strictly observe safety precautions. If industrial units are equipped with protective equipment, then in self-made devices you will have to make them yourself. You should know that the operation sharpened from the engine of the washing machine without protective casing is prohibited. It can be made of sheet metal with a thickness of 2.5 mm.

Working circle during sharpening experiencing a strong vibration.To prevent the destruction of sandpaper during operation, installing a stone, under the metal washers put a strip of cardboard. You should also make sure that the disk is not cracked.

During operation, you should stand at the side of the circle so that when it breaks, the fragments do not fly into the operator.

/rating_on.png)

/rating_off.png)