How to pick up staples for a furniture stapler

Construction stapler today is widely used by specialists of various professions. Various materials are combined with it. The presence of many different names, for example, Tacker, staple gun, stapler, nailer, emphasizes the popularity and versatility of this tool. But to work with such equipment, you need consumables: staples, nails or pins. In practice, the first version of fasteners is most often used. Consumables differ in shape, material from which they are made, geometrical parameters and other features. Staple sizes for staplers are a determining factor when choosing a fastener suitable for the model in use.

Content

Existing bracket types and sizes

Staples for the construction stapler are divided into separate groups according to different criteria, the main of which shape and size. On the first sign of consumables are the following varieties.

- U-shaped - the most common in practice, the most versatile rectangular version of fasteners.

- U-shaped - arc-shaped version designed to fasten wires and cables for various purposes, as well as different sections.

- T-shaped (pins, nails) - this is the most rarely encountered in practical activity consumables, allowing you to perform a connection that does not bear any load, the most hidden way.

Few models of staple guns can work with all three varieties. For most tackers, only U-shaped fasteners are suitable.

Parameters of U-shaped fasteners

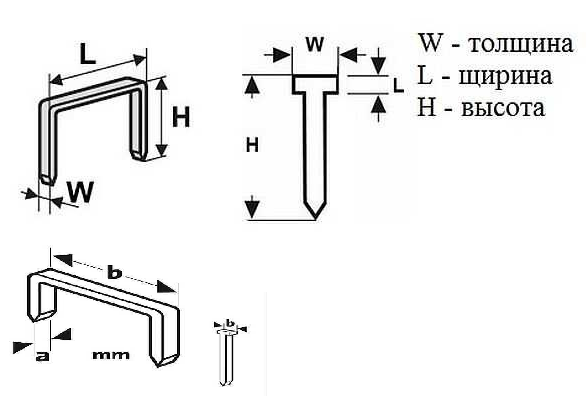

Consumables in the form of the letter "P" are characterized by three sizes:

- leg length or height of the bracket (denoted by the Latin letter H), defining the maximum possible depth of fasteners into the surface of the base material;

- the width of the "back" (the length of the bracket itself, indicated on the label as L or b), which is taken into account when masking the joint;

- thickness (width denoted by W or a), which determines the strength of fasteners made of different materials.

All sizes on markings represent in millimeters. The photo shows the U-shaped and T-shaped fasteners with the letter designation of their individual parts.

It should be borne in mind that the shorter the length of the shackle, the less load can sustain the mount.

Of all the significant range of U-shaped brackets the most demanded in practice Their types are:

- 53, having a bracket thickness of 0.7 mm, a length of 11.3 mm and a height of the leg from 4 to 14 mm;

- 140, characterized by a significant degree of rigidity, with dimensions: H - 6 ÷ 14 mm, L - 10.6 mm, W - 1.25 mm.

Other existing types of U-shaped consumables for frame sizes are rarely used.

Varieties of U-shaped and T-shaped consumables

Arc fasteners are designed for special modifications to furniture braces. There are only two types of such fasteners:

- 28 (in another way is indicated by a large Latin letter S), intended for fastening a cable with a cross section of 4.5 mm, having a clip thickness of 1.25 mm, and a leg height of 9 ÷ 11 mm;

- S6 (L is also recorded in the marking) is a semicircular fixture with a thickness of 1.25 mm and a leg height of 6 ÷ 10 mm, which is used to fix the wire with a diameter of 6 mm.

From nails, the following varieties have become practical:

- type 300 is a small T-shaped fasteners with a cap with a core thickness of 1.2 mm, used to attach different materials to plywood, wood, chipboard;

- type 500 - finishing version of nails without caps.

The length of both types of studs can only be 10, 12 or 14 mm.

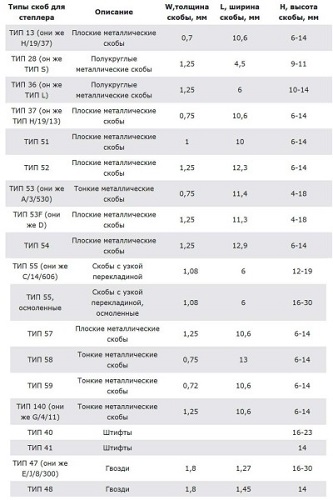

Considered varieties of consumables used when working with staples, are not limited. The table below shows common hardware for furniture screeds with their description and frame sizes.

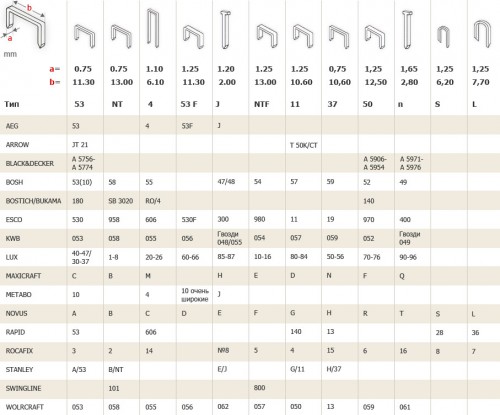

Virtually every company that produces construction staplers also produces consumables for them. In this case, the sizes of fasteners are standardized, but the markings on the products may vary. In order to understand the compliance of each other brackets, nails, pins from individual manufacturers use the table below.

Equal sizes of manufactured fasteners allow using consumables from different companies for staple guns.

Staple manufacturing material

Brackets for the electric stapler (as well as for mechanical and pneumatic) are made of different materials. According to this criterion, the following types of fasteners are distinguished:

- aluminum;

- copper;

- steel.

This determines not only the properties of fasteners, but also indicates the scope of their application.

Steel consumables for construction staplers

Because of its considerable strength, steel clamps are used in practice most often in various fields of activity. They can be red-hot or not. The first apply if you have to work with solid material. They are good to drive, but they break more easily without sustaining lateral loads.

The main disadvantage of both types of steel fasteners is their susceptibility to corrosion: they rust withby time. Especially fast corrosion processes take place in wet conditions. This spoils not only the appearance of the compound, but also reduces its strength.

Brackets for the stapler construction Steel 62125, T50, 14х10.6 mm

To extend the life of the steel brackets, they are coated with zinc. Galvanized products are sufficiently resistant to destruction, so it serves many times longer.

Also to prevent corrosion, fasteners are made of stainless steel. Such products are more expensive than ordinary metal products. Stainless steel brackets are very reliable because they are resistant to destruction. Galvanized and stainless consumables are produced mainly by well-known manufacturers who are worried about their reputation.

Aluminum and copper fasteners

Aluminum brackets are a cheap option. Products are resistant to corrosion, but they are of little strength: they can easily bend when driven in or burst from a relatively small load. For these reasons, the scope of application of aluminum consumables is limited work with soft materials: assembly of cardboard packaging, fixing of electrical wiring, as well as light plating.

Copper brackets for the furniture stapler are stronger than their aluminum counterparts. They are also resistant to corrosion and are suitable if you have to work with soft materials. In addition, the high cost limits the distribution of copper fasteners: they are mainly used when decorating.

Correct selection of brackets for the tool model and types of work

To choose the right consumables for the work, you need to focus on a number of criteria:

- the type of fastener for which the operated staple gun is designed, as well as its shape;

- the material of the base surface into which the fasteners are to be driven;

- future conditions in which the fasteners will be located after connecting the parts;

- the material from which consumables are made;

- the sharpness of the ends of the staples;

- quality consumables.

Instructions on the appropriate size and type of fasteners for charging the used model of a staple gun are on its packaging or in the instruction manual for the tool. This is mainly U-shaped consumables. The number of fasteners on the marking is represented by 2 numbers: the first one indicates the width of the bracket, and the second one indicates the height of its leg.

The choice of consumables from the size range indicated by the manufacturer of the staples is based on the value of the future load on the fastener: the higher its size, the larger must be the dimensions of the fastener. If the base material is solid, then steel or hardened staples will do. It is better that they have pointed ends - this will ensure easy driving in.

When it is required to make a joint that is not subject to the action of loads as imperceptible as possible, use the smallest possible consumables.

For use in wet conditions suitable copper, aluminum, galvanized brackets, or stainless steel. The best option depends on the hardness of the base, the degree of the upcoming load.

Cost and packaging of staples

Fasteners for staple guns are sold in boxes. In this case, in one package can be from 500 pieces to 5000 staples, fastened with adhesive film in separate blocks. They fit into the tool shop completely or they need to be divided into pieces of the desired size.

It is more convenient for work to pick up consumables that are immediately suitable for the length of the unit.

Prices for consumables, depending on the manufacturer, range from tens to hundreds of rubles per 1000 pieces. The difference is related to the metal from which enterprises manufacture products. It is recommended to purchase more expensive, but quality fasteners. Cheap consumables when driving in often bend or break. This significantly affects the duration and quality of work.

Brackets Stanley type-A (5/53/530) 8 mm

There are no trifles in the work of a professional. The correct choice of fasteners in size and material will not only increase productivity, but also improve the quality of the result. In addition to the types of brackets for tackers considered, individual manufacturers produce consumables of non-standard sizes and shapes. Such fasteners are suitable only for special modifications of construction takers. Often this tool is designed to perform only certain specific types of work.

/rating_off.png)