Woodworking opportunities

The modern market offers a variety of technical devices with which the user can express themselves in various types of creativity. It is even about making furniture yourself. To make it durable, good-quality, and most importantly, indistinguishable in appearance from production samples, use a special tool - a router on a tree.

Content

Tool features

The frezer is an apparatus for processing wood, less commonly used for metal. There are two main types of such equipment:

- stationary milling machinein which the milling cutter is fixed, and the workpiece is moved by the efforts of the operator;

- manual frezerwhich is manually moved along the fixed workpiece.

Manual frezer

The first type of device, as a rule, is used in manufacturing. In life, use the manual version of the tool.

By the way, if necessary, the hand mill can be fixed using various devices and turn it into a milling machine.

In addition to the task of working with flat surfaces, sawing with a router on a tree technological excavations (for example, notch for loops, tongue, groove, and so on). All these works can be done with a manual mill, and the result will look much more accurate, and the work itself will be faster than without using a tool.

With the help of such an “assistant”, people with little physical strength (women, teenagers, the elderly) can show interest in carpentry. This is understandable - when working with a tool, practically no effort is needed. However, before making plans for this activity, it is necessary to understand the structure of the apparatus and the peculiarities of its functioning.

How does the hand mill

The device of a manual mill on a tree is quite simple. The device has a case in which key components and elements are located. The most important of these is the driving force - the motor.Directly from the body stands holder - it will be collet inserts. These are special adapters in which you can insert and fix milling cutters of various diameters.

Separately worth mentioning about a platformwhich is usually made of metal. It can be fastened with rods to the body separately. The lower part has a sliding plate made of smooth material - this will help the tool to go smoothly from point to point. An important parameter is the stability of the platform. It is better if it is made of cast (for expensive models) or stamped (for budget options) material. This will ensure a better fit to the surface. The lower part of the platform is covered with a plastic lining, often removable, so that it is convenient to replace.

On the case there are buttons for on and off. Well, if they make a company lock button. When working comfortably use a parallel stop.

For a manual router, use the following settings:

- depth of work (step from 1 to 10 mm);

- regulation of the speed (that is, the speed of rotation of the cutter).

For all the details and components need appropriate care.In the newly purchased product such a role factory grease. However, in the future, this responsibility is placed on the user himself: it will be necessary to clean the dust and manually lubricate the moving parts.

It is not recommended to use thick mixtures, as dust and shavings settle and stick to them, which makes work difficult. There are no such problems with aerosol variants.

Types of cutters used

Each type of material processed involves the use of appropriate nozzles. Externally, the mill consists of two parts: the cutting edge (working part) and the shank. It is important to know that supple soft wood species are treated with lightweight materials, and for hard tree species, an appropriate hard cutter is needed.

There is another classification of nozzles:

- profile - simple processing of wood products;

- Cone-shaped - processing at an angle;

- rectangular - work with grooves;

- V-shaped for receiving holes with a 45-degree slope;

- disk - you can create different grooves in width and depth;

- hemmers help round the edge edge;

- seam for quarter milling;

- "Swallow's nest" - spike connection;

- fillet to create the same parts on the edges.

It is worth knowing: for a manual household router it is necessary to use non-bearing nozzles - this will help in processing tools in any convenient place.

Device features

With a frezer, a lot of tree operations are performed: the use of this device is limited only by the user's imagination. He is irreplaceable in the joinery and furniture workshops, will help when carrying out finishing and repair work. Among the most common features are:

- milling of quarters, grooves, grooves, both as an element of a design, and a decor;

- profiling using the edge (production of baseboards, platbands, curtain rods, glazing beads);

- solving household tasks - for example, grooves for locks in the door;

- creating holes (through or blind);

- treatment of the ends and edges;

- cutting patterns, parts, drawings.

Beginners should start with the simplest details. Later, users gain experience and skill - then you can make real masterpieces. Having learned to work well on the router, you can even create your own sought-after business.

How to use hand tools

The principle of operation is to drill certain holes with the cutters selected for this purpose and submerged to a depth determined by the user.

- The nozzle selected on diameter chooses.

- The shank snaps into the cartridge no more than 2 cm.

- Milling cutter is set to the desired depth.

- The adjustment knob is transferred to the middle position (between minus and plus).

Next, the regulator is configured rotation speed. This indicator must be selected based on the characteristics of the material. First, it is better to practice on the sample.

It is important to know: the larger the mill, the lower the rotational speed should be. At a cutter diameter of 1 cm, a speed of 20,000 rpm is made, and for a 4 cm nozzle it is necessary to set 10,000 rpm.

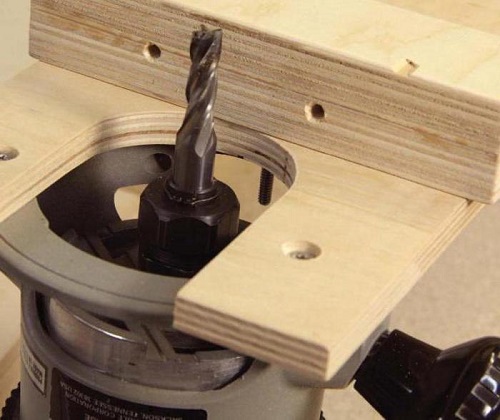

Usually requirements are specified in the attached manual. While working, the tool can be held in the hands as well as fixed on the table - The latter option should be used when processing small parts. When fixing on the table, the router should face the spindle upwards.

Fraser fixed on the bed

After turning on the instrument, it is important to adhere to the following rules. It is recommended to install on the working surface ruler guide (or arc-shaped pattern, if there is work on the semicircle). This will help create smooth lines. If we are talking about working on the router with different details in a variable profile, they will be useful. narrow cut ruler. They can be attached perpendicular to the workpiece.

It is necessary to use a milling cutter, without neglecting safety precautions, to eliminate the risk of injury.

- On the product, the device must be moved in the opposite direction from the movement of the cutter. Otherwise, you can not hold the device.

- It is important to take a stable position - it will help not to lose balance. All parts should also be firmly fixed.

- The tool must be held very tightly - contact with the material "gives" a small blow. Otherwise, the device may fly out of the hands and create a traumatic situation.

- The user should dress in special protective suit, refilled without the ability to wrap on plywood. For respiratory protection (fine dust may occur), it is recommended to wear a respirator.

- After completion of work or during a break, it is necessary to turn off the device from the network.

/rating_off.png)