Which concrete mixer is better to choose

Concrete is among the most common building materials. Its mechanical characteristics after curing largely depend on the quality of stirring. For mixing the working solution on construction sites and in everyday life used concrete mixers, which are also called concrete mixers. The use of this special equipment, as compared with the manual mixing of the prepared mixture with a shovel, can significantly increase productivity and also improve the quality of the poured concrete. The market is filled with models of various types with different technical and operational characteristics. This article will help you choose the best technology option, both for home and professional activities.

Content

Classification of concrete mixers

Concrete mixers are divided into individual types according to the following classification criteria:

- installation method;

- drive type;

- way of loading and unloading;

- mode of operation;

- working principle.

Consider in more detail each view.

By installation method

According to this criterion, the following types of concrete mixers are distinguished:

- stationary;

- mobile.

Mobile Concrete Mixer

Devices stationary type used with large amounts of work. They are large in size and mass.

Mobile technologyhaving rather compact dimensions and less weight, they are used when it is necessary to constantly move around the construction site. Also, mobile units are well suited for the preparation of concrete solution at a remote location of construction sites.

By type of drive

Concrete mixers are divided into two groups:

- mechanical (manual);

- automated.

Have automated devices the drive can be an electric motor or a fuel (gasoline or diesel) engine. Electric concrete mixer can be powered from a network of 220 V or 380 V. The performance of automated models is directly dependent on their power.

Manual Concrete Mixer driven by the muscular strength of the workers. Mechanical samples are characterized by a simple device, low cost, low weight, compactness, autonomy of work. But their performance is significantly inferior to automated models. Also, the quality of the resulting concrete solution may suffer when the worker is tired. Therefore, mechanical units are used mainly in everyday life.

Manual concrete mixer

In the professional activity, small teams engaged in finishing work use hand-made equipment to mix putty, plaster and other mixtures in small volumes.

By way of loading and unloading components

According to the method of filling components of concrete equipment is divided into the following groups:

- with manual loading;

- semi-automatic;

- with self-loading.

Self loading concrete mixer

Regarding the discharge, the classification is similar. The issuance of the finished solution can be mechanical (manual), semi-automatic or automatic way. Technique functioning in automatic modemore convenient. It provides high performance, but is more expensive.

According to the mode of operation

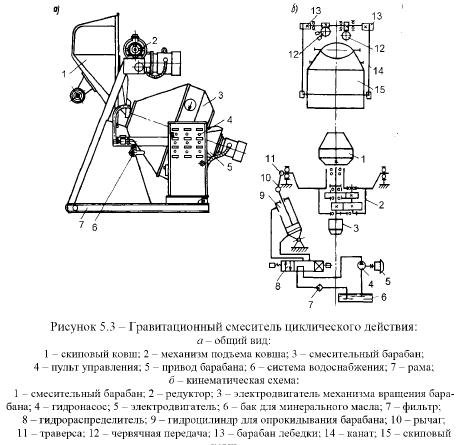

Here are the devices continuous and cyclic (temporary) action. The first are characterized by simpler design and high performance. They are used on large construction sites. The technique, which operates cyclically, the whole process is divided into 3 main stages:

- download;

- mixing;

- unloading.

The equipment of cyclic action is used in practice much more often than continuous.

By the principle of mixing

According to the method of mixing the components of the concrete mixer mixers are of two types:

- gravitational;

- forced.

Gravitational concrete mixer SBR-1200

Both varieties differ both constructively and in their capabilities. This leads to the presence of various advantages and disadvantages of them.

Advantages and disadvantages of gravity equipment

The gravitational concrete mixer mixes the components of the working solution due to the rotation of the drum, inside of which there are fixed blades, that is, the particles of the mixture are mixed as a result action of gravity.

The technique of gravitational principle of action according to the method of transferring rotation from the motor to the drum is divided into 2 subspecies:

- gearbox;

- coronary.

These subspecies differ in different criteria:

- price;

- durability and reliability;

- maintainability.

Models with gear - it is durable equipment, more reliable and less noisy in the work than coronary analogues. In units of this type, the transmission mechanism itself is well protected from the ingestion of particles of sand, crushed stone, cement and other building materials. But the technique requires a more careful and careful attitude, because in case of breakdown it is very difficult to repair it. In most cases, you will need to buy a new installation, as a quality repair is comparable to its price.

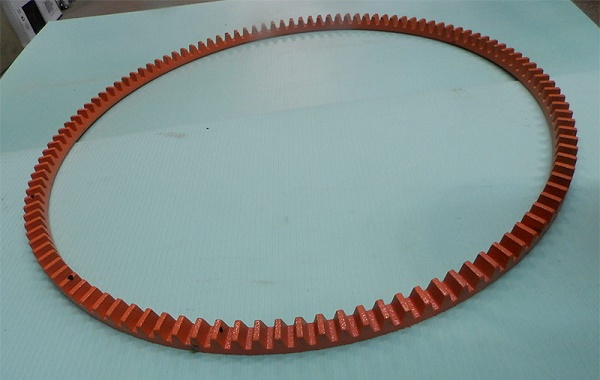

Venous models Concrete mixers are equipped with an unprotected transfer unit: the ring gear is fixed along the entire circumference of the drum.For this reason, it often fails due to clogging of building materials between the teeth. But such problems are eliminated by simple cleaning.

Due to the simplicity of maintenance and unpretentiousness in operation, concrete mixers with a crown are popular and in demand in the market of construction equipment.

The following advantages are peculiar to the equipment of gravitational action (regardless of the variety):

- unpretentious service;

- reliable and simple device;

- with significant volumes of mixed concrete, the equipment weighs little;

- ease of unloading: the solution is poured out by tilting, while nothing remains inside;

- it is possible to stir up concrete with a different size of components (even more than 100 mm);

- electric models have low power consumption due to low power of installed engines;

- profitability.

Along with this technique, such minuses are inherent:

- mixing the solution until it reaches a state of uniformity takes a long time;

- Concrete preparation with small fractional components is characterized by low efficiency;

- fibers or pigments do not mix well in a mixture.

Gravitational mini-concrete mixer (its bucket capacity is up to 50 liters) of cyclic type is a good option for infrequent household use. It takes up little space and is useful, for example, when pouring a screed. But for building a house or building a garage, models with a larger drum capacity are needed.

Pros and cons of forced-type concrete mixers of cyclic action

Forced concrete mixers are equipped with a fixed drum. Inside it is a screw (blades). The mixing of the concrete components is carried out at the same time due to its rotation. This design similar to a mixer.

A forced-action concrete mixer is able to mix well solutions of different consistency: both liquid and viscous. Due to the fact that the screw constantly rotates, a homogeneous mixture is obtained at the exit from the unit, which is distinguished by a high degree of plasticity.

The forced action technique is used to produce large volumes of concrete with a liquid consistency on large construction sites, but the aggregates are not capable of mixing the compositions with fillers of large sizes. For this reason, in many cases they are used. in conjunction with a concrete pumpwhich also cannot pump over concrete solution with large fractions.

Models without concrete pumps used for mixing plaster or putty, solution of sexual screed.

To reduce the load on the electric motor and increase its service life, forced-action units are equipped with powerful electric motors. This causes an increase in energy consumption and costs associated with it.

The most common forced concrete mixers cyclic type of two subspecies:

- with a horizontal shaft position, equipped with a cylindrical body;

- with its vertical arrangement, the body of which has a trough-shaped form.

Horizontal Shaft Models

A plus models with a horizontal shaft is a high quality mixing solution.

Cons much more:

- the big weight of the unit in comparison with the mixed volume;

- the difficulty of repairing the mixing unit;

- ready solution is discharged for a long time;

- suitable only small or medium size filler.

Vertical Shaft Technique

Merits Vertical shaft technology are:

- obtaining high-quality concrete at the exit;

- the possibility of obtaining mobile and sedentary concrete solutions, as well as molding compositions.

disadvantages This equipment has the following:

- increased motor power;

- can not be used to prepare the working solution of different density components.

The technique, which has a horizontal shaft, is inferior in universality to units with its vertical arrangement.

Planetary concrete mixer

There is also a more sophisticated planetary forced concrete mixer.

This species has the following advantages:

- with relatively little time, high-quality concrete will be obtained;

- high performance;

- the walls of the tank are well cleaned from the remnants of the solution with the help of special scrapers;

- the output is a high-quality building material, even when using fillers of different density.

Significant minus The planetary equipment is its high cost and technically sophisticated device. Acquire such equipment for use at home does not make sense.

Features of concrete mixers of continuous type

Continuous forced-type concrete mixers are distinguished by the presence of two shafts which during operation of the installation rotate in opposite directions (towards). They are often equipped with mobile and stationary plants that produce concrete. Long-term operation of the equipment ensures the presence of a steel case (or of durable brands of cast iron), covered with lining inside, mounted on the frame.

Due to the screw design of the blades, the solution moves towards the discharge opening. The two-shaft concrete mixer is equipped with an electric drive. Its performance is regulated by rotating the blades in the range of 0-90 degrees relative to the shaft axis.

The advantages of two-shaft concrete mixers are as follows:

- ease of use;

- high reliability;

- long service life;

- the possibility of obtaining high-quality concrete in significant volumes, of different consistency and with different sizes of fractions of fillers;

- the design of the unit allows you to replace some parts during the work process.

Among the minuses there is only a fairly high price. For home operation, twin-shaft models are not intended.

Concrete mixers with two shafts - this is a great option to make building mixes, trademarks of concrete. Thanks to their use it is possible to create reinforced concrete structures characterized by a high level of strength.

Equipment selection options

To choose a concrete mixer for home and cottage or professional use, you need to decide on the following factors:

- necessary volume of one batch;

- type of work for which you need to prepare a solution (for example, for plaster);

- with the type of mixture you need to get: its consistency, particle size of fillers.

After determining the appointment, the choice of a concrete mixer should be made taking into account the main criteria.

- Drive power and level of protection. The power of the operated unit largely determines the quality of mixing of heavy concrete or mixtures with large aggregate fillers. The important point is the ratio of this parameter with the capacity of the bucket. The greater the amount of concrete in a concrete mixer in cubes, the more powerful the installed motor must be.The engine itself must be well protected from water and dust particles.

- Capacity bucket (drum). For a home, it is enough to buy a concrete mixer with a drum capacity from 90 to 150 liters. In general, in terms of bucket volume, it is recommended to give preference to equipment, in which this parameter is one third more than necessary.

- Operating mode. Domestic concrete mixers are designed to operate on 220 V mains. At the same time, their capacity is up to 1 kW. Technique designed for 380 V, is more productive.

- Drum material. Concrete mixers are usually made of steel. If you count on the durability of the equipment, then the thickness of their walls should be at least 1 mm.

In addition to these criteria, it is recommended to take into account the following:

- fame of the manufacturer and reviews of the model you like online;

- the level of automation of the technological process of equipment is important for large volumes of work;

- warranty period (well, when its period is 2 years);

- availability of warranty service centers nearby will provide an opportunity to repair the operated equipment without any problems.

Among manufacturers leaders are such companies:

- Inforce;

- ZITREK;

- Denzel;

- Lebedyan;

- Prorab;

- Caliber;

- RedVerg.

Devices of domestic manufacturers at a lower cost have acceptable quality.

Have models with a gravitational principle of action it is necessary to consider whether they belong to the subspecies: to the gear or coronary. The latter version will be cheaper and easier to operate. It is necessary to consider the reliability of the crown. It is determined by the material from which this part is made. Such as steel, cast iron, polyamide, plastic. In continuous operation, it is recommended to give preference to mechanisms with steel or polyamide crown, which are the most durable and wear-resistant. Pig-iron or plastic transmission parts are suitable for rare use.

More convenient transportation around the construction site will make equipment with a locking mechanism of the concrete mixer wheels.

To perform large amounts of work on a professional basis (with small fractional fillers) need a technique with a forced principle of action. Household activities accompanied by the need to prepare different versions of the solutions used.For it, gravity installations with a power of about 700 watts will do. They are able to provide a sufficiently high performance at home.

/rating_off.png)