Choosing a good screwdriver for household or professional work.

Screwdriver is an indispensable tool for the repair and construction, finishing and homework. With it, you can quickly hang a shelf or a picture, disassemble and assemble furniture, drill holes, etc. If you are not yet the owner of this device, then before going to the store it is important to get acquainted with the information about what types of screwdrivers exist and what their technical characteristics are. This knowledge will help you choose a screwdriver that best suits your needs.

Content

Screwdriver classification

Manufacturers of devices for tightening screws in order to meet consumer demand offer various types of this tool. They may differ not only in functionality, but also in the type of power source. These devices are: electric, battery, combined, pneumatic, pulse (shock) and tape.

Electrical devices

Network screwdrivers are very similar to normal electric drill. But they differ from the drill by the presence of a torque regulator (ratchet). There is no clear indication of what value to put on the ratchet. Selection of the force with which the screw will twist, is carried out experimentally.

Electric screwdriver has its advantages over the battery counterparts:

- the possibility of a continuous workflow, since the device is powered via a cable from the electrical network

- the network device has high power independent of battery parameters (battery);

- less weight when compared with battery devices;

- reasonable price, which is significantly lower than the cost of devices with batteries.

Cordless tool

This type of device uses rechargeable batteries as a power source and has its advantages and disadvantages. The advantages of the device are obvious. If you compare it with network analogues, the radius of use of which depends on the length of the electric cable, the battery tool is devoid of this disadvantage. Since the tool does not depend on the power source, having it on its case, the work can be performed even when the power is turned off. Such screwdrivers are very convenient to use in places where access to the power grid is difficult, for example, in basements, on roofs or in summer cottages.

When buying a battery tool, it is recommended to immediately buy an additional battery, which will allow you to continue working when the battery is low.

The main drawback of the device with the battery is low engine powerdepending on the state of the battery.For long and energy-intensive work, such a device will not work.

Combined devices - This is a universal type of screwdrivers. They are created specifically for those who need and battery, and network. Combined screwdrivers can work both from the battery and from the electrical network.

Pneumatic devices

Devices powered by compressed air coming from a compressor are called pneumatic.

This type of device is high performance, has a small mass, is used both in production and in everyday life. Pneumatic screwdriver can be used in rooms with high humidity and in places with high explosiveness. But for the operation of the tool requires a compressor.

Impulse machines

Pulsed-type devices are compact tools with high torque. This is achieved due to the automatic transition of the tool into the shock-pulse mode, due to which, with the help of frequent impulses, spindle braking is overcome. Rotation of the cartridge slows down, and torque increases sharply.

Benefits:

- torque, if, for comparison, take an unstressed screwdriver, 3-4 times stronger with the same voltage;

- pulsed screwdriver is lightweight and compact;

- when tightening self-tapping screws of large sizes, the operator’s hand is not subjected to heavy loads, the impact screwdriver can be held with one hand, almost without straining;

- suitable for drilling deep and large holes, as due to the pulse mode, the drill does not jam in the material;

- not so fast wear bits.

Disadvantages:

- while the machine is operating in pulsed mode loud crackling, and with large amounts of work, the operator is recommended to wear headphones;

- before switching on the pulse mode, the cartridge rotates at high speeds, which requires caution and habituation to the operation of this tool;

- chuck can only be clamped хвост inch hex shanks.

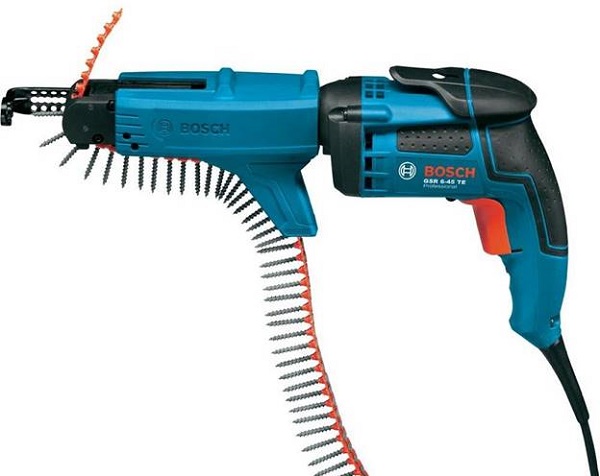

Tape machines

Belt screwdrivers are used when performing large volumes of identical operations, for example, when finishing rooms, when you need to tighten a huge amount of fasteners.

This unit is automatic screwdriver with feeding screws through a special nozzle, which is filled with plastic holder with fasteners. When pressing the nose of the device on the surface to be treated, the screw is tightened. When you release the clip moves, and the next screw is ready for screwing.

Usually the tape is designed for 50 fasteners. In it you can fill the screws, designed for both drywall and wood.

Basic tool selection options

Choosing a screwdriver, it is necessary to pay attention to its technical characteristics, because only in this case you can choose a reliable and high-quality tool that meets your requirements.

Power

From this indicator depends tool productivity. Accordingly, the higher the power of the screwdriver, the faster the work will progress. For accumulator devices, the power indicator directly depends on the characteristics of the battery, and for the network ones, it depends on the consumed electrical energy. As a rule, device power ranges from 0.5 to 0.7 kW. But to perform some complex operations you may need a unit with a power of 0.85 kW and above.

Torque

It is the main characteristic for a screwdriver and is measured in newtons per meter (Nm). This parameter is determined by the power of the engine and the characteristics of the battery. Torque in the screwdriver affects the force with which the machine will tighten the screws.

The technical documentation for the device usually indicates what the maximum length and diameter of the screw can be tightened with this tool. There are units with a maximum torque of 130 Nm.

For a home there will be enough device with a torque ranging from 10 to 12 Nm.

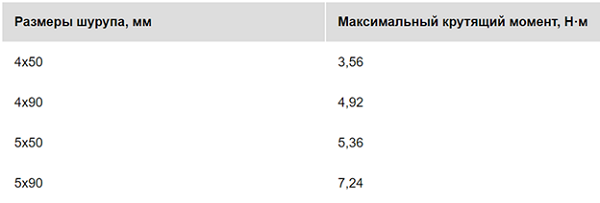

Below is a table from which you can understand what torque is required to tighten fasteners of different sizes.

It is worth noting that the data in the table can not be taken as a standard. These values are averaged and do not reflect the real picture. For example, the same 4x50 screw can be twisted in soft wood (linden, pine) with a torque of 3.56 Nm, but with the same effort, twisting it into a birch will not work.

Rotation frequency

This indicator characterizes the frequency of rotation of the spindle of the apparatus and is measured in rpm.The rotation speed is switched by a special button. More precisely, this button toggles operation modes of the gearbox. Most screwdrivers have 2 speeds. The next photo shows the gearbox gearshift button.

The very speed of rotation of the spindle, from 0 to maximum speed, can be adjusted by gradually pressing the trigger (start button). Choosing this tool, you should not strive for large indicators of speeds. For work with fasteners, a speed of 500 rev / min is sufficient, and for drilling 1200-1500 rev / min.

Type of cartridge

Almost all screwdrivers are installed keyless chucks. They allow you to easily and quickly change the working tool (drills, bits). On the device can be installed as two-sleeve and one-footed cartridges.

To change the tool in the 2-socket chuck, it is necessary to hold the lower sleeve with one hand and unscrew or twist the upper one with the other. In one-chuck, all operations are done with one hand. However, it is necessary that the spindle lock option be provided in the unit. But in practice, the wizard quickly change the snap-in, holding the cartridge sleeve with one hand and including the rotation of the spindle in the right direction (clockwise or against).

Cam cartridges used in screwdrivers quite rarely. To clamp the drill bit or bit into the chuck, a special key is used, which is lost all the time. In addition, the change of the working tool takes a lot of time.

Weight

This indicator is important when choosing a suitable tool. Of course, it is much easier to work with a lightweight device. But it is worth considering the fact that the lighter the tool, the less power the engine has. Also in the lightweight devices installed batteries of small capacity. An example of a lightweight power tool is electric screwdriver.

It is convenient to use it for small jobs that do not require much effort when tightening fasteners. For household use, suitable tools weighing up to 1.5 kg. This tool has enough power and is quite satisfied with the home master.

Electromechanical quality tool

When buying a power tool, you need to find out information about the type of its gearbox (speed transmission mechanism) and the electric drive.

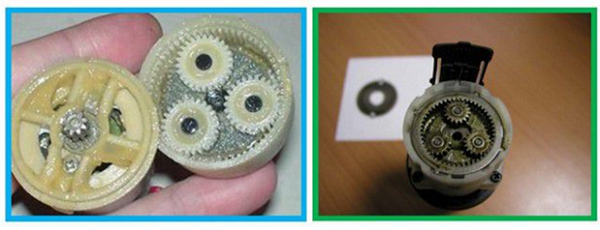

Gearbox

The transmission mechanism turns significant load during operation of the tool.Therefore, ask the seller what material is made gear gear. It is on the type of material depends on the life of the device, as well as its functionality.

It is easy to guess that the resource of plastic gears is much lower. It is better to give preference to the apparatus with metal gearbox.

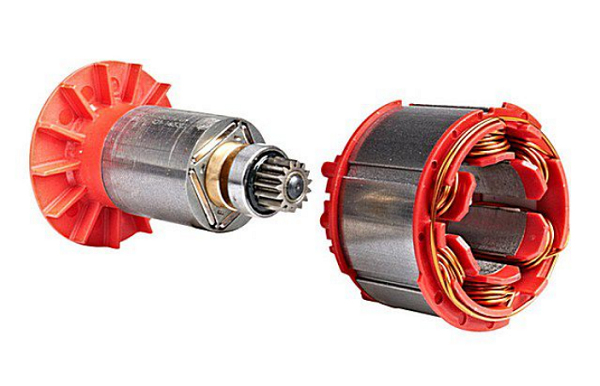

Drive unit

In budget models of devices, traditional, time-tested electric collector motors with electric brushes are used. Despite the fact that these engines are reliable enough, they have one drawback: when electric brushes touch the collector lamellae, friction forces are inevitably created, as a result of which thermal energy is released and the engine heats up quickly. In more expensive models of screwdrivers installed brushless drive without the above shortcomings. Due to the lack of a friction area, the productivity of the device increases several times.

The tests showed that if you take two models of screwdrivers with the same characteristics and the same battery, but with different drives, the brushless unit will work 3 times longer than its collector counterpart.

Useful additions

Reverse - quite a useful feature that facilitates the work. The ability to switch the direction of rotation of the spindle is useful if you need not only to tighten the screws, but also to twist them.

It is very important when choosing this power tool so that it has forced braking function. That is, after you release the “Start” button, the spindle should immediately stop. If this function is not in your chosen model, you should not acquire it. The rotation of the spindle inertia after turning off the electric motor gives a lot of inconvenience. Changing the equipment quickly will not work, because you have to wait for a full stop.

Uncontrolled rotation of the spindle can lead to injuries, for example, if the drill is wound on the user's clothing.

Battery specifications for cordless screwdrivers

The power of the battery tool, as well as the duration of its work, is determined by the characteristics of the battery.

Battery types

Ni-Cd - Nickel Cadmium Battery. Their characteristic difference from other types of batteries is that such batteries can be used at lower temperatures (from 0 ° C and below).Also, batteries have a sufficiently long service life under the condition of proper operation, low cost and up to 1000 effective charge cycles.

The disadvantages of nickel-cadmium batteries can be attributed to their rapid self-discharge and mandatory complete discharge before connecting to the charger. This requirement is explained by the presence of a memory effect on the battery, due to which the capacity of the battery further decreases.

Ni-MH - nickel-metal hydride batteries. They have a large capacity, compared to Ni-Cd batteries, and a greater number of charge-discharge cycles (up to 1500). The disadvantages of these batteries are as follows:

- high price;

- fast discharge at high loads;

- inability to use at low temperatures.

Li-ion - Li-ion batteries. They have a large capacity and keep it for a long time, they charge quickly. But lithium-ion batteries are not adapted to work at low temperatures and quickly lose their charge. In addition, lithium-ion type batteries can not be completely discharged. As a result, the battery capacity is reduced, and it fails after several cycles of complete discharge.

When buying a tool with a lithium battery, be sure to check the date of production of the battery. Unlike other types, Li-ion batteries have a limited shelf life.

Capacity

From this parameter depends on the time during which the tool will work effectively. The higher the battery capacity indicator, the longer the device will work without recharging. But do not forget that whatever battery you choose, its capacity will gradually decrease over time.

Voltage

This battery parameter directly affects torque and may be in the range from 9 to 36 V. The lower the voltage, the lower the torque. For example, if the battery voltage is 9 volts, then this will not be enough for drilling and mounting wooden structures, twisting long screws, etc. For such works, a device with a battery having a voltage of 12-14 V is suitable.

The difference of professional tools from home

By appointment, usually distinguished professional and domestic screwdrivers. Before purchasing this device, you should understand the purpose of the tool and the expected scope of work. For infrequent use of the tool with small loads suitable household models of devices. But if you have to use the unit constantly, with large loads and without interruption in work, then you should opt for models designed for professionals.

Household appliances

Household devices have a small capacity and, accordingly, the same performance. They are intended for periodic use for a short time, with interruptions in work to cool the engine. For homework, a device with a torque of 10-15 Nm and a rotational speed of 350-500 rpm will suffice.

Professional devices

Professional tools are used in manufacturing or construction for laborious and complex operations. As a rule, such a tool is made of materials resistant to wear, has great power and is designed for continuous application. A professional tool can have a chuck speed of up to 1,300 rpm or more, and a torque of 120-130 Nm. Based on the foregoing, for construction and repair, as well as for production work, it is better to purchase a professional cordless or cordless screwdriver.

Overview of the best manufacturers

Undoubtedly, the choice of a screwdriver should occur according to many criteria, the main one of which can be considered a manufacturing company that has its service centers in your region of residence.We list the best manufacturers of screwdrivers for 2017, which can no doubt be trusted.

- Company “Makita”Is a leader in the production of various types of power tools. The company's products are of the highest quality and reliability. Therefore, if you want to buy a good tool, then choosing a device from this manufacturer, you will make a successful purchase.

- “Bosch ” as well as “Makita”, occupies a leading position in the production of power tools. If you have a question, what brand is better to buy the device, Makita or Bosch, then it is difficult to answer this question. Both manufacturers produce both domestic and professional quality screwdrivers. In any case, you will not be disappointed.

- Power Tools BrandAEG”Cheap cannot be called, although the quality justifies its investment.

- Brand Instrument “DeWALT”, Always distinguished by innovative developments. Therefore, if there is a desire to purchase equipment with the latest state-of-the-art developments in place, select the DeWALT screwdrivers.

- Company “Metabo”Equips its products with electronics, for example, regulating the amount of torque.But the traditional power tools of this brand are also of the highest quality.

- Tool makersHitachi, Sparky, Skil"Produce products that are in good demand and have affordable prices.

- Domestic manufacturers "Interskol "," Caliber "and" Bison”Also well proven in the market of power tools. Although they lose a little in some positions to foreign brands, the quality and reliability of products attracts a domestic buyer. Moreover, the prices of the tool are low, and service is available in almost all regions.

Focusing on the above, you can understand that buying devices of unknown origin and unknown brands, to put it mildly, is not recommended. Of course, such a device can work for a long time under domestic conditions, but if you break it, you will not be able to hand it over for service.

/rating_off.png)