Which welding machine to choose

Semi-automatic welding machine is an improvement on standard welding equipment. Due to the special design of the unit, the working process is significantly accelerated. Semiautomatic devices are widely used not only in factories, but also in small workshops.

Content

Advantages and disadvantages of semi-automatic

Semi-automatic welding machines are popular not only among professionals, but also among home craftsmen, as they have a number of advantages over conventional welding machines.The main advantages of semi-automatic include the following:

- the ability to cook aluminum, cast iron, structural steel and other metals;

- the apparatus can be used to cook both thin sheet steel (at least 0.5 mm) and thick;

- it is not required to smooth the edges to shine;

- the device is easily configured for different operating modes;

- high speed;

- affordable price;

- low toxicity of smoke, when compared with the work of conventional electrodes;

- wide gaps can be filled with metal;

- when working clearly visible welding bathwhich is not filled with slag masses;

- the seams are distinguished by their tightness, which is important for connections for gases and liquids;

- when using the MIG / MAG method, a small amount of spatter is generated;

- suture requires minor processing;

- Easy to learn all the options and settings for beginners.

Also, semi-automatic and have some drawbacks.

- Bad job in open space (on the street). It is necessary to close the place of work from the wind, as it blows off the protective gas from under the burner.

- When working with MIG / MAG methods gas cylinder, which has considerable weight and inconvenient to transport.In addition, it must be periodically taken to the gas station.

- When operating without protective gas, the radiation from the electric arc increases and increases sprinkling hot metal.

What is better - an inverter or semi-automatic

If we compare two types of devices, it becomes obvious that the inverter works with electrodes, and the semiautomatic device with electrode wire, as with a powder coating, and copperplated. In the latter case, it is required to use a shielding gas to blow the burning point of the electrode, thereby creating a better and more aesthetic weld than when welding with a conventional electrode. Semiautomatic machines are more suitable for working with stainless steel, aluminum and other “difficult” metals.

In addition, the semi-automatic can splice thin metal parts, for example, in car body repair, which cannot be done with an ordinary inverter. It is especially convenient to work with a semiautomatic device in hard-to-reach places, since the length of the electrode wire does not interfere with operation. When working with an inverter, it is sometimes difficult to reach any junction due to the length of the electrode. In such cases, it has to be shortened, which takes time.The need for constant replacement of the electrode greatly reduces productivity.

But inverters have a huge advantage over semi-automatic - mobility and compact size. The device easily moves from one place of work to another, for example, when installing a long fence or installing billboards. Therefore, the inverter can be considered a more versatile device. Semiautomatic is more likely to stationary equipmentwhich is used within the workshop or workshop area, since it has a greater mass than the inverter, and it is inconvenient to constantly move it along with the balloon and hoses.

Summing up, we can say that the semi-automatic is more suitable for professional use when regular welding is required. To perform various connections at the household level, an inverter will be sufficient, especially if it is supposed to be used occasionally.

Inverter type semiautomatic devices

Not so long ago, units appeared on the market, representing a combination of an inverter and a semiautomatic device. Inverter semi-automatic welding machine, as the name implies,uses the inverter converter as a current source.

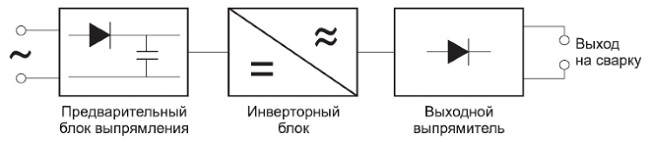

For reference! The inverter operates according to the following principle. The alternating current coming from the mains, passing through the diode bridge, is rectified. Further, already direct current passes through transistors, transforming it again into an alternating, but high-frequency current. The high frequency current is reduced by the transformer, while the voltage decreases and the current increases. This current enters the output rectifier, where it is again converted to a constant.

Thanks to this technology, the dimensions of the unit are significantly reduced, and the high-frequency characteristics of the current have a positive effect on the stability of the welding arc. In addition, the main difference between inverters is high efficiencybecause energy is not wasted on heating the iron of a large transformer.

Invert semiautomatic devices are used in large and small enterprises, in construction and automotive workshops. With the help of these devices perform welding of any metals, both homogeneous and dissimilar; the connection of parts of large thickness and welding of thin sheet metals; continuous seams of great length, etc.

The semiautomatic invertor welding machine has its advantages over the usual semiautomatic device:

- welds are of the highest quality;

- excellent ergonomics;

- low power consumption;

- low weight;

- smooth adjustment of welding current;

- compact size;

- protection from sticking of the electrode;

- hot start function;

- Pulse / Superpulse modes (used to work on thin sheet steels);

- arc boost;

- high efficiency;

- built-in cooling system;

- overheating protection;

- thanks to microprocessor control, the device can carry out self-diagnostics, launch suitable welding programs, recognize burners, etc.

Also on inverter semiautomatic devices can there are additional modes, for example, polarity change or MMA welding, that is, stick electrodes, which greatly expands the capabilities of the unit.

Technical parameters for the selection of semi-automatic

First of all, when choosing semi-automatic devices, you need to have an idea about the intensity with which they will be used, since the units are produced in 3 categories

- Household. Can be connected to a 220-V household power supply and are not designed for continuous use.After a short period of time (indicated in the instructions), the device must be given time to cool down. Household models of welders produce a current in the range of 200 A and can work with or without protective gases, i.e., powder wire electrodes;

- Semi-professional. They can produce welding current up to 300 A. The devices use electrode wire paired with protective gases. Welding can be carried out using the MIG / MAG method, as well as powder-coated electrode wire (MMA method).

- Professional. The units operate on 380 V mains and are designed for continuous operation. The magnitude of the current in them can reach 400 A. Semiautomatic devices can produce MMA, MIG and MAG welding, as well as boil in pulsed mode and work with tungsten electrodes, using argon arc welding (TIG).

Network voltage

Since the semiautomatic devices operate on electricity, it is necessary to properly select the device for mains voltage:

- for domestic use it is required that the device be connected to a 220 V network, that is, to a regular outlet;

- at the enterprises and in small workshops where there is a three-phase network, it is better to use professional equipment capable of operating from 380 V;

- there are units that have combined type of connectionwhich can work both from a three-phase network, and from single-phase.

You should also consider network load carrying capacity. If, when a device with a load of 2-3 kW is connected to it, the voltage drops below 200 V, then it would be better to choose an inverter semiautomatic device that works more stably in the shrouded networks (voltage ranges with which the equipment can operate, are indicated in its instructions).

If under load the network voltage drops to 150 V, then no semiautomatic device will work under such conditions. In such cases, you will need to use a gasoline generator or purchase a conventional inverter unit (not a semi-automatic) to power the device. In addition, the inverter must be PFC power factor adjustment, thanks to which the device can work even at voltages up to 100 V.

Current strength

This parameter is essential for any welding machine. The rated current depends on the thickness of the metal to be welded and on the diameter of the electrode wire.

Choosing a semiautomatic device according to the strength of current, it is necessary to consider the following conditions.

- When the thickness of the metal is not more than 5 mm, the welding current is sufficient in the range of 150-200 A. At the same time, the diameter of the electrode wire should be from 0.8 to 1.0 mm.

- For metal with a thickness greater than 5 mm, a welding current of up to 250 A is required, and in some cases even higher. The thickness of the wire should already be 1.2-1.6 mm.

The table below shows the data that can be used for welding low-alloyed and carbon steels in carbon dioxide.

When choosing a device, it is desirable that there is a small supply of amperage, approximately 50 A. This will make it possible to use equipment without current limit values and unit overheating. In addition, in a thinned network or when using long cables, the amperage is less important than the calculated one. Often, for promotional purposes, the manufacturer deliberately overstates the figures in the passport data for equipment, which in reality do not correspond to the declared ones.

Load duration

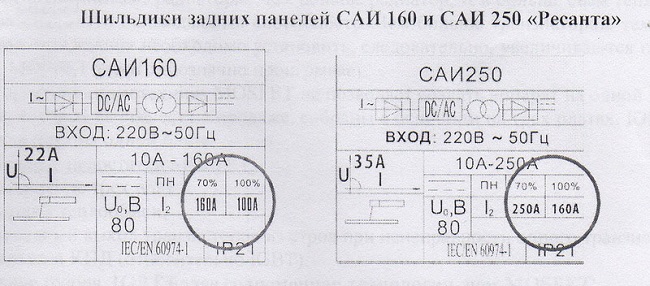

This parameter must be considered in order to prevent overheating of equipment. The duration of the working cycle is expressed as a percentage and is equal to 10 minutes (10 minutes = 100%). This indicator means for how long the device will be able to work at maximum loads until shutdown. The following figure shows where the duration of the load (PN) is indicated on the machine.

Also in the figure you can see with what current the device can work for a certain time at maximum load. For example, if the value of 50% of the device after every 5 minutes of work is required to give 5 minutes to rest, that is, the work cycle can be designated as 50/50. But if PN = 60% and higher (which is typical for equipment of the pro class), at an ambient temperature of 20 degrees the equipment will work at a maximum of 6 minutes, after which it needs to rest for 4 minutes.

As practice shows, to work in the mode when MON = 100% is not necessary. On average, a PN for a welder working on a semiautomatic device is 60% - this is due to inevitable technological stops. Therefore, having an apparatus with PN = 60%, it is possible and not to make special stops in work for its cooling.

Welding methods and additional features

All semiautomatic machines have welding modes using MIG / MAG protective gases. But invertor semi-automatic devices can work in the MMA mode.

- MIG (Metal Inert Gas) - In this method, inert gases are used, for example, argon or its mixture with carbon dioxide.

- MAG (Metal Active Gas) - welding method using active gases. The most common and economical gas for this purpose is carbon dioxide.

- Mma - The method of conventional arc welding using electrodes (electrode wire) having a protective coating.

In addition to welding methods, it is desirable that the equipment has additional functions that facilitate the work.

- Hot start - hot start function, helps in ignition of the arc, for example, when the voltage drops in the network or when welding rusty metal.

- Arc force - This is a function of arc stabilization. If for any reason the arc starts to die, then the apparatus increases the strength of the current, thereby stabilizing its burning.

- Anti stick - the presence of this function eliminates sticking of the electrode to the metal during operation.

Also important is the presence of the TIG mode, which allows the use of tungsten electrodes in a protective argon gas medium.Thanks to this mode, it is possible to weld practically any metals.

Overview of popular models of semi-automatic

Many manufacturers put up their products on the welding equipment market, and it is quite difficult for a beginner to choose a suitable automatic welding machine from the whole variety. Market flooded Chinese-made deviceswhich have low cost, but do not differ in high quality, and especially reliability. On the other hand, well-known brands from European and American manufacturers are quite expensive, and not every home artist can decide to buy them for household use.

European manufacturers

Wester MIG 180. This invertor semiautomatic device is developed in Germany, but is issued at the Chinese plants. But despite this, the semi-automatic machine has good build quality and high reliability. The manufacturer gives him a 3 year warranty, which also confirms the good quality of products.

The device is household, consumes 7.5 kW of electricity and is capable of producing a current of up to 180 A. The minimum wire diameter that can be used on it is 0.6 mm. If you look at the reviews on the Internet, left in relation to the semi-automatic Wester MIG 180, then among them there are practically no negative ones.

Telwin BIMAX 152 TURBO. This is a semi-automatic from the Italian manufacturer, which is a leader in the manufacture of welding equipment.

The device at the output produces a constant current ranging from 30 to 145 A, consumes 3.7 kW, and can operate in MIG / MAG welding modes. The wire feeder is built into the unit.

FUBAG IRMIG 200. This is a semi-automatic inverter from the German manufacturer, proven to be highly reliable. This device get for small productions, auto repair shops and for construction. With a price of about 20 thousand rubles, the semi-automatic is interesting for the following features:

- smooth adjustment of current;

- the feeding device for the inverter is built into the housing and operates in automatic mode;

- the device can work not only in the mode of semi-automatic welding (MIG / MAG), but also in the manual MMA method;

- due to the forced cooling system, overheating of the main modules of the device, which can operate at temperatures from -10 to + 40 ° С, is prevented;

- The semiautomatic has a Euro connector for connecting the burner to it.

This model has a mass of 15.4 kg and compact dimensions, so that it is convenient to take it to various objects, carry it within the yard, etc.

American manufacturers

LINCOLN Handy Mig - pretty high quality semi-automatic transformer from the US manufacturer.

The device can be used for welding most metals. But its main purpose is MIG / MAG thin sheet metal welding. LINCOLN Handy Mig has a maximum welding current of 80 A, 4 levels of voltage regulation and a smooth adjustment of the electrode wire feed.

Russian manufacturers

Interskol ISP-200/7 from the Russian manufacturer is an inverter semi-automatic.

The device is able to work as a method of MIG / MAG, and using stick electrodes (MMA). The developers made sure that the semi-automatic could work with significant voltage drops in the range from 160 to 240 V.

In addition, the model attracts the domestic buyer with the following characteristics:

- effective ventilation system eliminates overheating;

- compact size and low weight (12.6 kg);

- a wide range of welding current settings, from 20 A (for thin-walled metals) to 200 A;

- low cost, within 18 thousand rubles.

Fast and Furious 200 PA. This welding inverter can work as a semiautomatic device, performing traditional types of MIG / MAG welding, as well as a conventional welding machine that uses piece electrodes (MMA method). The equipment also allows the use of argon-arc welding (TIG).

The semiautomatic device can generate welding current ranging from 15 to 200 A for all types of welding. Wire thickness up to 1.6 mm and electrodes up to 5 mm in diameter can be used with the device.

Summing up, we can conclude that domestic welding equipment is no different from foreign analogues, and in some respects it exceeds them. In addition, prices for Russian semi-automatic are more accessiblethat is important for most consumers.

/rating_off.png)