Adjusting the ignition on the chainsaw

A separate class of chain saws as a power unit uses gasoline engines. They are necessarily equipped with an ignition system that is responsible for the timely ignition of the air-fuel mixture in the cylinders by means of an electric discharge, which breaks through the space between the electrodes of the spark plugs. From the moment at which the spark arises, depends on the correct operation of the motor. The inspection of the technical state of the ignition system of the acquired gasoline saw should be given special attention. In specialized stores, equipment is sold in a healthy way, but if the setting is knocked down, you can set the ignition on the chainsaw on your own.

Content

Device and principle of operation of the chainsaw ignition system

The standard ignition engine carburetor engine consists of:

- magneto;

- spark plug;

- electrical cable connecting them to each other;

- engine mute keys.

Ignition chainsaw "Ural"

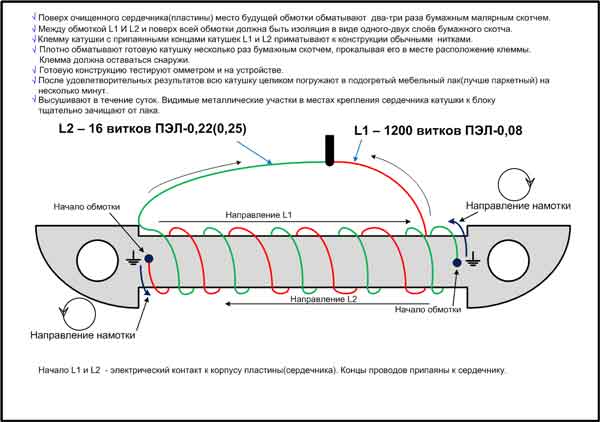

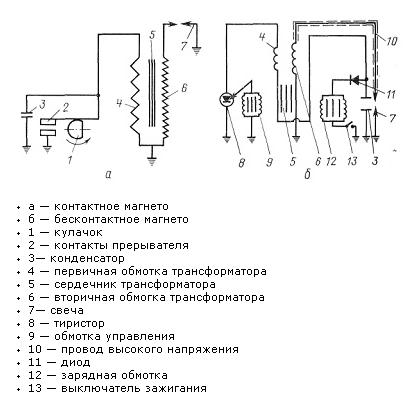

Magneto is a type of alternator that supplies spark plugs with electricity. It consists of a fixed winding of an inductor and a permanent magnet mounted on a flywheel rotating with the crankshaft of a gasoline engine. A moving magnetic field creates an electromotive force in the low-voltage winding, which is converted by the transformer into voltage with a potential sufficient to produce a spark.

Have contact magneto the first lead of the high-voltage winding is connected to the spark plug, and the second through a mechanical switch to the ground. At a certain moment, a special element of the structure divorces the contacts, which leads to a sharp increase in the voltage in the network and the leakage of a spark in the interelectrode space of the spark plug.

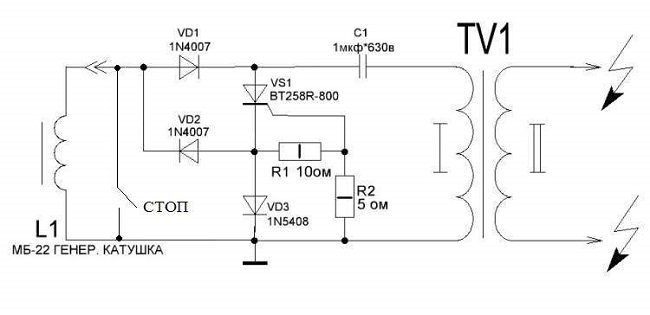

To prevent overheating and oxidation of the breaker contacts, a capacitor is connected to the electrical circuit.

Chainsaw ignition circuit with contactless magneto based on the operation of the control coil, which plays the role of a voltage supply regulator. The electronic unit also includes a diode, a capacitor and a thyristor that transmits a current with a voltage of a certain magnitude. When it is opened, the capacitor is intensively discharged, forming a current in the turns of the primary winding, which is induced in high voltage, giving a breakdown on the spark plug installed in the cylinder. The electrical network operates in a pulsed mode in time with the rotation of the crankshaft and the translational motion of the cylinders.

Ignition timing

The mechanical device and the factory setting of the magneto ensure the coincidence of the discharge time of the candle with the optimal position of the moving piston. For four-stroke gasoline engines, a spark must occur before the piston reaches the top dead center - this is because the process of completely igniting the air-fuel mixture takes a certain amount of time. The speed of the engine parts is comparable to the rate of ignition of the fuel, so the piston from the moment of the breakthrough of the spark until the burning gases create an extremely high pressure has time to go some way.

For each engine there is ignition timing. It is equal to the crank rotation expressed in degrees from the moment of breakdown in the interelectrode space of the spark plug to the moment when the piston is in the top dead center. This indicator depends on many parameters, including the design features of the engine and the properties of the fuel mixture.

In practice, in the case of mass production of the engine at the factory, individual adjustment of the ignition of each product is not carried out, but corresponding marks are placed on the rotating parts, which must be combined during installation.

In what cases is the ignition setting required? There are major failure symptoms in the system:

- engine does not start;

- the motor works, but with noticeable interruptions;

- there is a decrease in tool power.

In these cases, do not rush to contact the service center. Try first to adjust the ignition yourself.

The procedure for checking and setting the engine to work properly

The most vulnerable element of the carburetor engine is a candle. It also allows you to judge the likely causes of failure of individual units of a gasoline engine.The following procedure is recommended.

- Remove the candle and inspect it. A dry candle with a slight brown tinge of electrodes can be considered good.

Nagar on the spark plug

- When detecting traces of fuel on the candle should check the carburetorwhich gives the cylinder an excess amount of gasoline, filling it. The presence of dark bloom indicates a probable change in the geometry of the cylinder or piston.

- If the appearance of the candle revealed no abnormalities, check the performance of the electrical circuit. First, a high-voltage cable supplying voltage to the candle is brought to the cylinder with a small gap and set in motion the starter cord. In this case, a spark of breakdown should occur. Its absence may indicate a cable fault. In this case, it is checked with a tester and replaced with a serviceable one if it detects its breakdown or damage to the insulation.

- In the case of serviceability of the high-voltage cable should check ignition coil and the wire going to the disconnect button. If a visual inspection does not reveal any obvious damage, it is necessary to ring the ignition coil, comparing the tester's testimony with the characteristics,specified in the instruction manual chainsaws. If a fault is detected, you will have to replace the entire unit with a similar one.

Chainsaw Ignition Coil

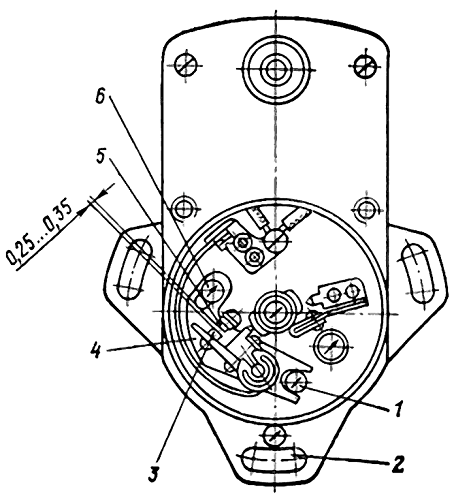

In the process of installing on the engine a new electrical module, you must adjust the magneto gap. The optimal distance between the flywheel and the ignition coil for most chainsaws is 0.2-0.4 mm.

Gap between magneto and flywheel

For fidelity, it is recommended to carefully study the documentation for the purchased model and follow the manufacturer's requirements.

With such a small gap, it will not be possible to use an available measuring tool for direct measurement. In practice, for the saw Husqvarna apply strip patterncut from thin and flexible sheet material of the required thickness. It is clamped in the space between the flywheel and the coil when it is installed, and then pulled out.

In order not to resort to adjusting the ignition, operate the tool carefully, avoiding shock. In particular, this applies to chainsaws with electronic chips in the ignition system, since they are very sensitive to mechanical damage.

/rating_off.png)