Compressor Air Dryer

The air compressed by the compressor often has particles of moisture or oil, the entry of which into the system is undesirable. To remove impurities from compressed air, install a dehumidifier for the compressor. In some cases, without this element, performance of work with the use of pneumatic tools becomes impossible.

Content

Purpose of a moisture separator in compressors

For the organization of proper operation of the pneumotool, a very important indicator is the purity of the compressed air that is fed to it. First of all, it must be dust free.Used for cleaning from mechanical impurities air filter, installed at the entrance to the unit. Also, it is necessary to remove moisture from the air masses, which, when compressed, condenses in the receiver and in the system itself. To remove moisture at the outlet of the compressor, an air dryer is installed.. In addition to moisture, compressed air can have oil particleswhich inevitably fall into it.

On a note! Mixing oil with air during its compression is typical for an air piston and rotary (screw) compressor, since the operation of these units implies the presence of lubricant.

If the air is not cleaned from moisture, then the following happens:

- when mixing moisture with oil, an emulsion is formed, which is capable clog up the pneumatic channels;

- at low temperatures, moisture in the pneumatic canals freezes, which can cause blockages or damage;

- rust accumulates in the air ducts, which over time can completely shut off the air supply;

- when moisture gets into the pneumatic tool, parts start to rust and quickly fail;

- the air-oil mixture that is formed cannot correspond in its compositionrequirements for its application in the food, electronic, pharmaceutical and chemical industries;

- in the presence of moisture quality painting becomes impossible, for example, cars, because the paint will fall loosely, with the formation of bubbles that will cause it to peel off.

Device and principle of work of a detail

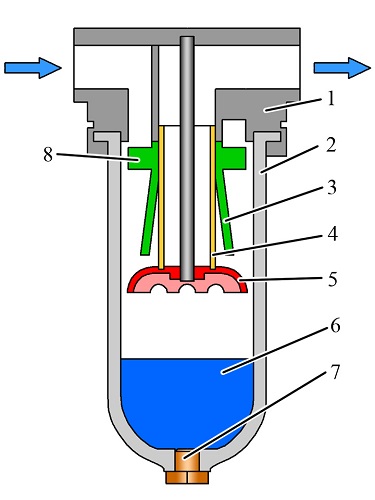

The device is a standard moisture separator vortex type for pneumatic systems shown in the figure below.

This node consists of the following elements.

- Housing. Attached to the pneumatic duct and is the basis for the entire dehumidifier.

- Glass. Forms an internal cavity in which the deflector (3), filter (4), damper (5), stopper (7) and impeller (8) are placed.

The principle of operation of the moisture separator simple enough. After entering the body (1) of compressed air, it moves in the direction of the impeller (8). Once on the impeller, which has guide blades, the air twists. Under the action of centrifugal force, all particles in the air move to the walls of the glass (2), where they condense and roll down. To separate the quiet zone in which there are pollution (6), a valve (5) is provided.Further, the air flow enters the deflector (3) with the filter (4) installed, which retains small solid particles of pollution. The accumulated pollution is removed through the plug (7) installed at the bottom of the glass.

Varieties of air purification systems

For cleaning compressed air, both for industrial and domestic purposes, several types of dehumidifiers are used: vortex, moisture and oil separators, adsorption and modular purification systems.

Vortex filters

The moisture oil separator of the vortex type has a cylindrical shape (the device was discussed above) and purifies the air due to its turbulence in the chamber (glass). Vortex oil separator is the most common device for cleaning compressed air from moisture and grease particles.

Adsorption moisture separators

To remove oil and moisture from compressed air, substances with active absorbing properties are used, for example, silica gel, alumogel, calcium chloride et al. The following figure shows an adsorption type oil separator.

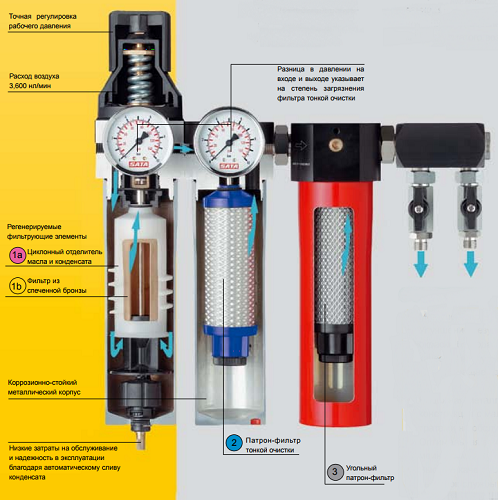

Modular cleaning systems

The best results in removing condensate, oil and dust particles from the air are provided by a modular cleaning system.. It consists of several elements: a cyclone (vortex) separator, a fine filter and a carbon filter. The following figure shows a modular type oil separator.

Important! At the last level of cleaning, modular systems provide almost one hundred percent purity of technical air supplied to blow guns, pneumatic tools, spray guns and respirators (not having a carbon filter).

How to make a dehumidifier with your own hands

Since the design of the moisture separator does not include high-tech elements, it is quite possible to make an air dryer for compressors with your own hands from the materials at hand.

Cyclone (Vortex) Moisture Separator

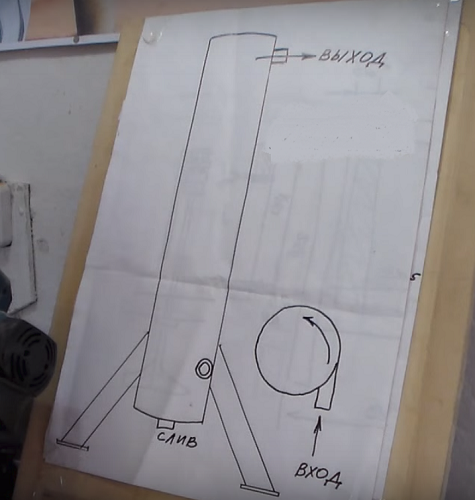

A cyclone valgoobotdelitel can be made from a cylinder for liquefied gas, an unnecessary fire extinguisher or pruning metal pipe of suitable diameter. The length of the pipe can be arbitrary.

The device is made in the following order.

- Drill a hole in the lower part of the body and weld the usual tap. It will serve to drain the condensate accumulated in the tank.Below is a drawing of a homemade vortex moisture separator, according to which you can make this device from a metal pipe.

- In the upper part of the body should weld the outlet fitting.

- A hole is made in the lower part of the tube (cylinder) (not lower than 150 mm from the bottom) and the inlet fitting is welded in such a way that the air enters the tank tangentially. Due to this, turbulence will occur in the vessel, which will facilitate the cleaning of the flow from contamination.

- Further, it is necessary to weld 3 legs with heels (for stability) to the body.

- If desired, the resulting fixture can be painted.

Tip! For proper operation of the device, it must be installed vertically.

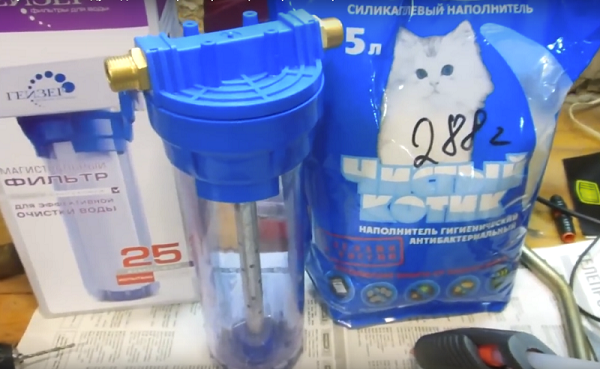

Homemade adsorption moisture separator

It is easy to make a homemade air dryer from a water filter and silica gel litter for cat litter.

You will also need a small metal or plastic tube and a glue gun.

The filter air purification from condensate is made as follows.

- Cut the tube so long as it enters the cap and reaches the bottom of the filter.

- In the tube it is necessary to drill several holes through which the compressed air from the compressor will pass.

- At one end of the tube, you need to insert a cap, so that when lowering it in silica gel, it does not clog.

- The upper end of the tube must be inserted into the filter cover and sealed at the junction using an adhesive gun.

- At the top of the tube or in the cap is necessary set grid, which will prevent filler from entering the duct.

- Next, you should pour the silica gel filler into the flask, insert a tube with a cap into it and screw in well.

Now you can connect a hose from the compressor to the inlet nozzle of the dehumidifier, and to the output one - a hose leading to any pneumatic tool, for example, to an airbrush.

/rating_off.png)