Heating in a private house using circulating pumps

Today you rarely find a house heating system built according to the classical gravitational scheme. Almost everywhere used circulating pump for heating. This device is useful and functional, but it reduces the general requirements for the accuracy of the design of the pipeline network. At the same time, without a forced source of circulation, the operation of such technological heating systems in a private house or apartment, such as a heated floor, is impossible.

Content

Design and principle of operation of the circulation pump

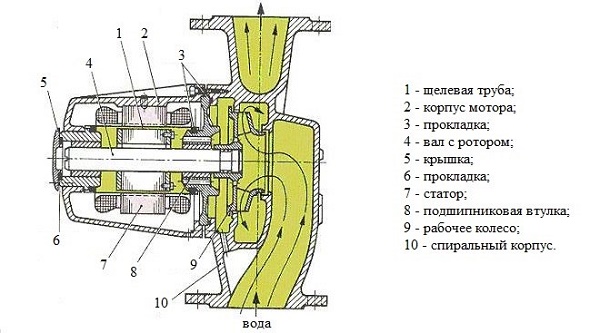

The device of the circulation pump - the implementation of the standard scheme centrifugal machine. The main structural units include:

- pump casing;

- a rotor that transmits rotation from the motor shaft to the turbine unit;

- turbine impeller with inclined blades, which is also called the impeller;

- means of sealing, isolation from water or coolant;

- the main electrical circuit that switches modes of operation and monitors engine parameters.

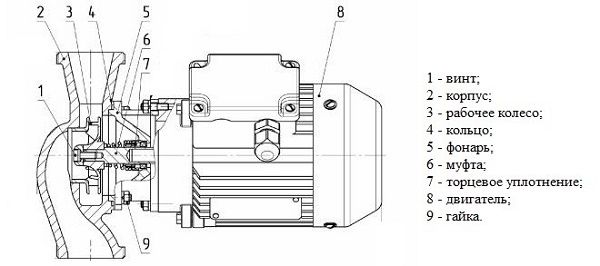

Circulation pumps may have a different body shape and location of the discharge and inlet nozzles. This is done so that the device is simply mounted, serviced under the operating conditions for which it was designed. In particular, the selection of the pump can be done according to the type of connection: with a flange, a threaded connection, a nut.

The circulating pump has small dimensions. It is often embedded directly into the internal cavity of the housing of household gas heating boilers. Assembly with the pump can be installed safety devices.The small size of the supercharger is easy to understand, given the purpose of the circulation pumps. They are not required to record the power of the fluid. In fact, they move the water literally in a horizontal direction.

The task of circulation pumps is to overcome the hydraulic resistance of pipelines. If the collector group of a heated floor is considered, the blower is busy creating a stream of a very small volume as such, since there are no significant gravitational forces in this type of heating circuit.

The principle of the circulation pump can be illustrated with a few points.

- The coolant enters the inlet.

- When the engine is turned on, the torque is transmitted through the rotor to the turbine wheel.

- Rotating, the wheel with inclined blades moves the water, which moves to the edge of the disk under the action of mechanics (distribution of forces on an inclined plane), as well as due to centrifugal force.

- As you approach the edge of the disk, the flow rate of water increases, as does its pressure.

- Liquid is discharged into the outlet.

As the water or coolant moves to the edge of the turbine wheel, an underpressure occurs in the inlet nozzle; it captures a new portion of the working fluid for transportation.

Important! The circulation pump of a gas or solid fuel boiler is able to efficiently maintain a certain length of pipelines, pumping the amount of coolant stated in the specifications. If you need more performance and pressure - it is not necessary to buy a separate, external supercharger. In the system, you can install an additional pump that will create the necessary flow or help raise the water to the second floor. The same is done when a distributed, zoned floor heating system is built.

Both conventional home and dual pump heating systems can use different types of blowers. The main difference between the models offered on the market in the engineering solution of the rotor-turbine zone.

Wet Rotor Pumps

Pumps for circulation with a wet rotor - the most common type of supercharger for the heating system of a private house or apartment. The devices are so named due to the fact that the operation of the nodes occurs directly in the coolant.

- The rotor is placed in a special glass with sealing or vortex leakage protection.

- During operation, parts of the rotor, including plain bearings, are in the water or coolant.

- There is a continuous lubrication and cooling of parts of the structure.

Thanks to such features of work, wet systems are distinguished by stability, no need for maintenance, low noise.

To prevent air from entering the rotor area, the pump is equipped with exhaust outlets. The upper one is designed to operate an automated system, and through the gas in the front of the case, gas is released during commissioning or adjustment.

Important! Running a pump with a wet rotor under the condition that air enters the pipelines causes sharply increasing wear of moving parts, overheating, seizure, or irreparable damage to equipment. The presence of abrasive particles in the coolant is not recommended. Therefore, the water pump with a wet rotor should be installed only in a closed heating system.

Dry rotor pumps

The pump with a dry rotor is executed with carefully isolating the turbine block from leaks. The system has several advantages and disadvantages.

- The advantage of dry systems in better cooling - most of the nodes are not in contact in the heating system with a hot coolant.

- Dry pumps are noisier.

- The overall level of reliability of pumps with a dry rotor is lower due to the greater number of seals, the lack of constant lubrication.

However, the main advantage of dry-type blowers is that they are not afraid of airing.. They are also less hampered by abrasive suspension in water - only the turbine suffers from it, whose output to failure is much higher than that of the rotor unit with its sliding bearings. Therefore, such blowers should be chosen if an open heating system with a circulating pump is built.

Speed-controlled pumps

The speed of the pump in the heating system plays a big role. With the help of its changes can be achieved:

- optimum operating mode of the heating equipment;

- stabilization of the temperature of all radiators, regardless of the range of their location from the boiler;

- reduce the temperature of the coolant at a constant heating efficiency, since at a higher circulation rate water every passage loses less energy.

Today, various technical solutions for pumps are on the market. Home heating can use a one-speed model, the performance of which must be chosen according to the characteristics of the boiler and the total volume of coolant. Are offered two, three, four speed models. Their work is based on changing the switching pattern of the pole pairs of the motor.

A more technological, but also significantly expensive solution is frequency control. The pump of this type provides not step switching, but smooth regulation of speed. This allows you to fine-tune the work of the heating circuit.

The use of circulating pumps in the heating of the house

Since some features of the operation of circulating pumps for water in various heating schemes have already been mentioned above, it is necessary to take a closer look at the main features of their organization. It is worth noting that in any case the supercharger is placed on the return flow pipe, if the domestic heating implies raising the liquid to the second floor - another instance of the supercharger is installed there.

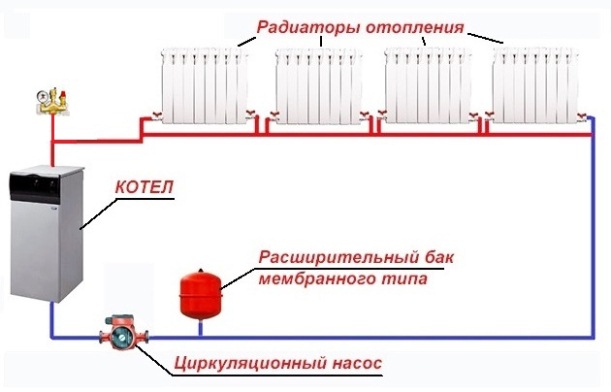

Closed system

The most important feature of a closed heating system - sealing. Here:

- the heat carrier does not come into contact with the air in the room;

- inside a sealed piping system, pressure is above atmospheric;

- the expansion tank is built according to the hydro-compensator scheme, with a membrane and an area of air that creates back pressure and compensates for the expansion of the coolant when heated.

On a note! For a closed circuit, you can make an expansion tank with your own hands. Its capacity is calculated by simple formulas, depending on the total volume of water in the system.

The advantages of a closed heating system are numerous. These include the ability to conduct desalting of the coolant for zero sediment and scale on the boiler heat exchanger, and pouring antifreeze to prevent freezing, and the ability to use a wide range of compounds and substances for heat transfer, ranging from water-alcohol solution to engine oil.

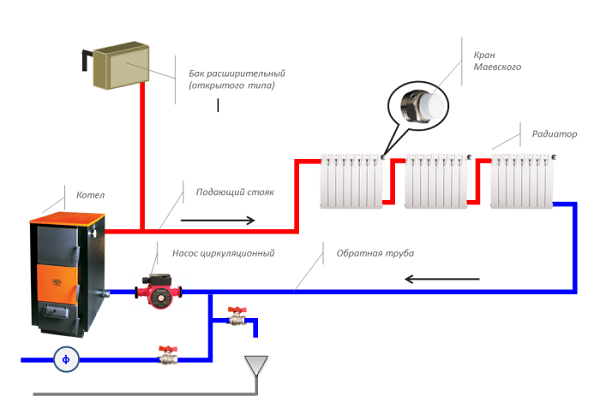

The scheme of a closed heating system with a single-pipe and two-pipe pump is as follows:

When installing Mayevsky nuts on radiators of heating, the setting of the circuit is improved; a separate air exhaust system and fuses in front of the circulation pump are not needed.

Important! The closed heating system, built without the inclination of pipes, respecting the level of the main lines of movement of the coolant, does not work without a circulation pump. It also does not function when the power is turned off.

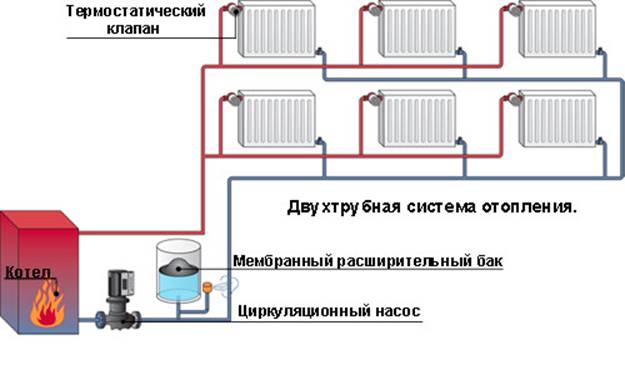

Open heating system

The external characteristics of an open system are similar to a closed one: the same piping, radiators, expansion tank. But there are cardinal differences in the mechanics of work.

- The main driving force of the coolant - gravitational. Heated water rises up through the expansion pipe, to increase circulation, it is recommended to do it as long as possible.

- The supply and return pipes are inclined.

- Expansion tank - open type. In it, the coolant is in contact with air.

- The pressure inside the open heating system is atmospheric.

- The circulation pump, installed on the return flow, acts as a circulation booster.Its task is also to compensate for the shortcomings of the piping system: excessive hydraulic resistance due to excessive joints and turning, violation of tilt angles and other things.

An open heating system requires maintenance, in particular, constant topping up of the coolant to compensate for evaporation from an open tank. Also in the network of pipelines and radiators are constantly undergoing corrosion processes, because of which the water is saturated with abrasive particles, and it is recommended to install dry rotor circulating pump.

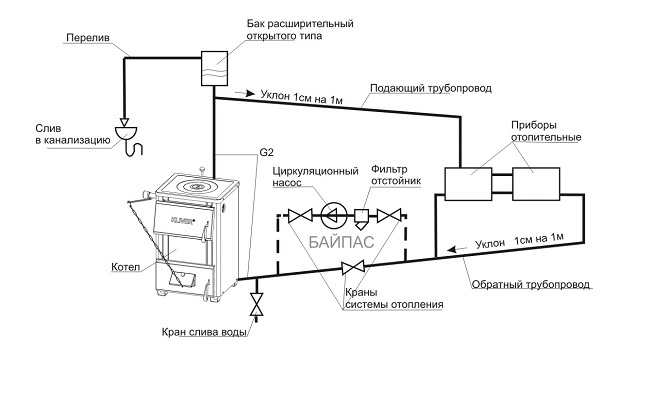

The scheme of the open heating system is as follows:

An open heating system with correct angles of inclination and a sufficient height of the accelerating tube can be operated and at power off (termination of the circulation pump). To do this, in the structure of the pipelines make bypass. The heating scheme looks like this:

When the supply of electricity is stopped, it is enough to open the valve on the bypass loop so that the system continues to work on the gravity circulation circuit. This unit also makes it easier to start the heating.

Floor heating system

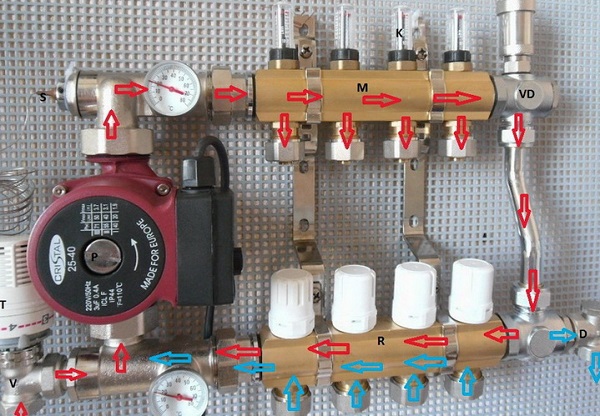

In a warm floor system, the correct calculation of the circulating pump and the choice of a reliable model is a guarantee of stable system operation. Without the forced injection of water, such a structure simply cannot work. Principle of installation of the pump following:

- hot water is fed to the inlet pipe from the boiler, which is mixed through the mixer unit with the return floor of the heated floor;

- the supply manifold for underfloor heating is connected to the outlet of the pump.

Distribution and control unit underfloor heating is as follows:

The system works according to the following principle.

- At the inlet of the pump is installed main thermostatmanaging the mixing unit. It can receive data from an external source, for example, remote sensors in a room.

- Hot water comes to the supply manifold at a set temperature and diverges through a network of underfloor heating.

- The return flow has a lower temperature than the flow from the boiler.

- The thermostat with the help of the mixer unit changes the proportions of the hot flow of the boiler and the cooled return flow.

- Water is pumped through the pump at a set temperature to the inlet distribution manifold of a heated floor.

Important! In such a structure there is no gravitational component of the circulation. Therefore, when you turn off the power and pump the floor heating simply does not work.

Main characteristics of circulation pumps

The main characteristics by which the choice of the circulation pump is made:

- headshowing the ability of the device to raise water to a certain height;

- performance and consumptionshowing how much fluid the supercharger delivers per unit of time.

These parameters are key in the calculation of the heating system. The head will allow you to understand whether the supercharger is able to maintain the pipeline network with a certain height difference. And the consumption is calculated according to the requirements of the heating boiler for the planned coolant volume.

Another factor that is often very important to the user is the installation size of the device. This is the size of the pump, it is meticulously considered if the supercharger is planned to be embedded into an existing pipeline, while ensuring a neat and inconspicuous installation.

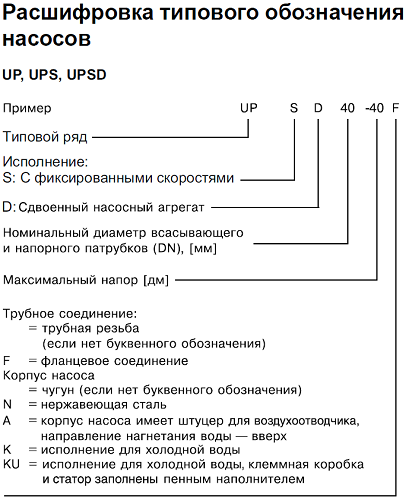

All the data the user needs contains front panel marking. The numbers on the circulation pump mean:

- device type (most often it is UP - circulating);

- type of speed adjustment (not specified - single speed, S - speed switching, E - smooth frequency regulation);

- nozzle diameter (indicated in millimeters, means the internal dimension of the pipe);

- head in decimeters or meters (may vary from different manufacturers);

- mounting dimension.

The marking of the pump contains information about the types of connections of the inlet and outlet pipes. The complete coding scheme and the sequence of words is as follows:

Responsible manufacturers always follow standard labeling rules. However, individual companies may not specify part of the data, for example, the mounting dimension. It needs to be recognized directly from the documentation for the device.

Tips for choosing a circulation pump

The choice of the circulating pump is always done after careful calculation, which takes into account the type of heating equipment, the volume of coolant, elevation changes, the minimum required performance of the supercharger.

Therefore it is worth choosing a pump only from proven brands. Reliable devices are presented in the middle price category. And if you need the highest quality and have the opportunity to pay a half to two times more - you should pay attention to the products of the brands GRUNDOFS, WILO.

Browse popular models

It is impossible to give a clear name of the best model among the superchargers without a clear segmentation according to their operating conditions. Therefore, the rating of circulating pumps for heating is the competition of brands and key features of the equipment they offer.

1. Grundfos UPS

One of the most popular and quality types of pumps. A company with roots in Denmark provided maximum reliability using stainless sleeves, ceramic bearings, turbine wheels made of composite materials. Wet rotor pumps feature the following features:

- low power consumption, from 45 to 220 W;

- very low noise level (up to 43 dB) and vibrations - you can understand that the pump is working, you can only put a hand on it;

- wide temperature range from 2 (-20 for individual models) to 110 degrees Celsius;

- simple installation;

- unpretentiousness, lack of service;

- durability, service life is at least 10 years.

Grundfos UPS pumps are very compact and lightweight. Their disadvantages include high price up to 2 times higher than competitors. However, the popularity of products of this brand suggests that their characteristics justify the price tag.

Pump Grundfos UPS 25/40

2. Wilo Star-RS

Products of this brand are considered the most reliable. In their design and electronic circuits, only proven and simple solutions are used. Pumps are characterized by:

- profitability;

- simple power adjustment;

- reliability, durability - cast-iron casing, turbine wheel made of polypropylene, bearings from metal graphite, stainless steel shafts;

- working temperature from -10 to 110 degrees Celsius;

- protection from surges and surges;

- ease of installation.

Wilo Star-RS pumps are compact, lightweight, maintenance free. Their price is also higher than competitors, but lower than that of the leader of the rating. Users note that at the highest speed the pump starts to make noise over time.

Pump Wilo STAR-RS25 / 4-130

3. Dzhileks "Compass"

The Circle series is a sensible choice, a strong middling with attractive features and value. Pumps are distinguished by:

- profitability;

- simple speed switch;

- small dimensions;

- quite low noise level up to 65 dB;

- rich equipment and easy installation;

- fault tolerance due to the lack of complex technical solutions and the use of reliable materials;

- low price.

The manufacturing company has an extensive service network, however, users note that the pumps of the Jilex “Circular” series extremely rarely break.

Pump Dzhileks "Compass" 25/60

4. DAB VA

A series of pumps from the Italian manufacturer is optimal balance of performance and price. They are not able to offer record numbers, but are reliable, adapted to the realities of domestic power grids. Devices characterize:

- three-stage speed adjustment;

- easy installation using a quick coupling;

- two types of mounting dimensions of 130 and 180 mm;

- noise level up to 70 dB;

- affordable cost.

On a note! Today, the market presents an updated line of DAB VA, where the issue of reliability has been carefully developed.A cast aluminum engine casing, a technopolymer turbine wheel, a ceramic shaft and thrust bearing, graphite bushings, many stainless steel parts and a new generation of sealing rings in EPDM are used.

Circulation pump DAB VB 55/120

Conclusion

Today on the market you can buy any circulation pump. In addition to those presented in the ranking above, are offered adaptive systems, self-determining parameters of the working fluid and changing performance. For the user, the main thing is to correctly calculate the required performance of the supercharger. And then, if you do not buy frankly junk products of the Chinese garage industry, the heating system with a high-quality pump will function for a long time, smoothly and stably.

/rating_off.png)