Proper installation of the circulation pump in the heating system

Modern heating system is economical, convenient and manageable. However, the practice of its organization often contradicts the principles of constructing such structures. In an average apartment or a one-story cottage, it is difficult to implement the classical gravitational mechanics of the coolant movement. Installing a circulation pump will allow the heating system to achieve a good level of stability and efficiency. Such a device is also useful in structures with a gravitational component of the coolant movement, and a heated floor without a forced supercharger simply does not work.

Content

The choice of the place of installation of the pump in the heating system

A modern circulation pump is quite a technological device. It uses components and materials that can work for a long time at high temperatures. Therefore, the installation of the blower in the heating system of a private house can be done almost without regard to the parameters of the coolant and other criteria.

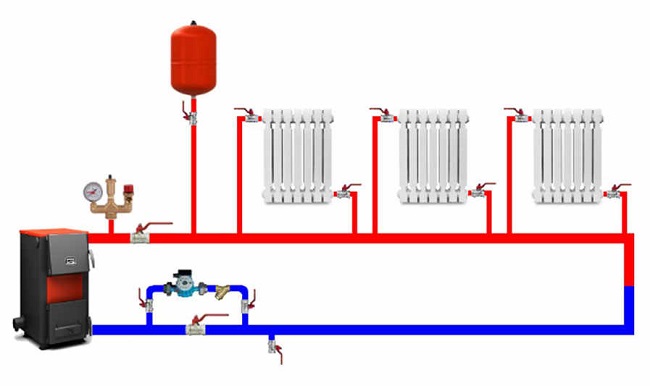

To extend the service life of the device, to ensure optimum working conditions for it, it is recommended to install the pump according to standard requirements, namely, on the return flow of the heating system, where the coolant has a lower temperature. At the same time there are several simple rules for the organization of circulation systems, both open and closed.

- A circulating pump must be installed on each closed heating circuit. This rule is always observed when heating individual parts of a private house or when supplying coolant to apartment radiators and heated floors.

- Installation of an additional pump produced in buildings where the network of pipelines is quite long. It is recommended to mount another blower if the pipe length is 80 meters or more.

- If the flow and return flow vary in temperature by more than 20 degrees - this means the need to install a feed pump in a system with natural circulation. additional superchargerif existing does not cope with the task.

- Control of the circulating pump by changes in its speed can not only provide the best heating mode, but also save money thanks to optimal working conditions of the boiler.

Supercharger easy to install with your own hands. At the same time, it is necessary to choose the right place for installation according to the requirements of optimal equipment operation. At the same time, convenient adjustment of the heating pump and access for its quick dismantling for repair should be provided.

The rules for selecting a point in the heating system, where the installation of a forced circulation device is being done, are fairly simple and straightforward.

- The pump must be as close as possible to the heating equipment.

- It is recommended to install the device on the return pipe.

- Both when installed on the supply line and on the return pipe, there should be no pipe elbows between the boiler and the circulation pump, except for special pipes designed for system maintenance.

According to standard rules, the connection scheme of the supercharger should provide for the possibility of isolating the installation point for dismantling, ensure equipment operation in normal mode, ensure easy maintenance of the system, and commissioning.

Binding schemes of heating systems

Building a line of presentation for a quick understanding of the features of the organization of various heating systems, it is reasonable to start with the option with forced circulation.

With forced circulation

This scheme has a number of features.

- Height differences, pipe slopes, the location of radiators relative to the heating boiler are not regulated in any way.

- The system uses multi-point equipment or a single-point air exhaust system (Mayevsky taps on radiators or one outlet point with the highest level of height).

- It is allowed to organize an arbitrarily large number of isolated circulation circuits, each of which is serviced by a separate pump.

The main feature of the system with forced circulation is that it cannot work without the operation of a circulation pump. Therefore, when the power is turned off, the coolant stops, the rooms are not heated.

Important! If a power outage occurs at negative air temperatures, the system with forced circulation requires an emergency drain, if the time to restore operation allows the coolant to freeze.For this, emergency discharge points are necessarily provided, in several places the structure of pipes with a low level. This does not need to be done if the system is closed and the coolant does not provide for freezing at low temperatures.

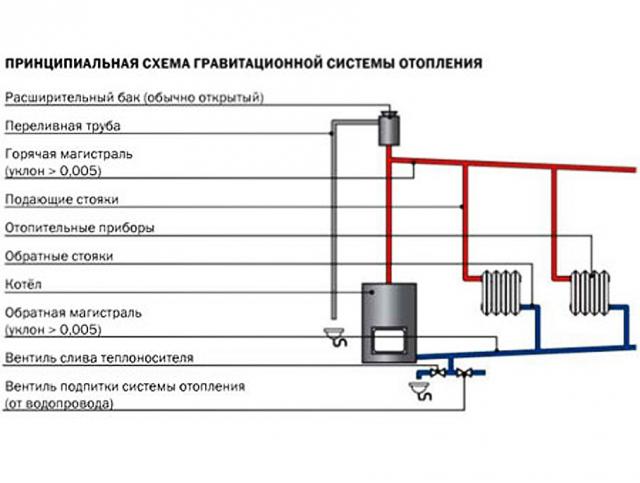

With natural circulation

A system with natural circulation has several advantages, but requires strict adherence to the rules of the organization. Its features are as follows.

- After the heating boiler, an acceleration line is provided, a vertical pipe, which allows to create pressure during the expansion of the coolant for its movement through the network.

- A clear parameter of the slope of both the supply and return pipes is regulated.

- With multiple heating circuits it is difficult or impossible to achieve optimal heat transfer in each of them.

The control of the circulating pump by the movement of the coolant can dramatically increase the functionality, efficiency, customizability of the heating system with natural circulation.

Such a system allows to solve a number of standard tasks:

- level design errors and overcome the hydraulic resistance of the pipeline network;

- to optimize the loading of the heating circuits when installing several pumps, to regulate the heat release;

- improve the working conditions of the heating equipment.

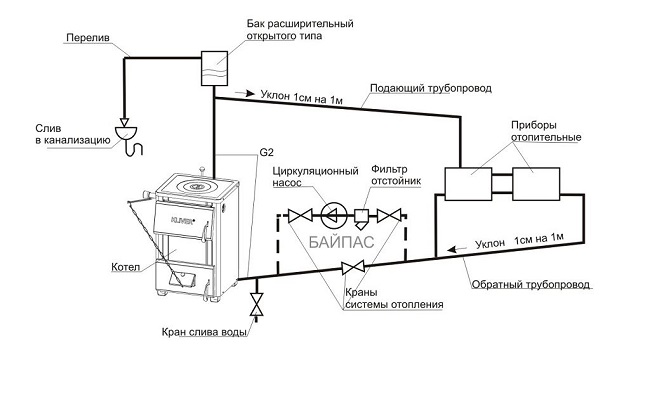

The main advantage of the system with natural circulation, for all the complexity of its organization, is the ability to work when power is disconnected. To achieve this, the circulation pump set to bypass. This is a fairly simple structure.

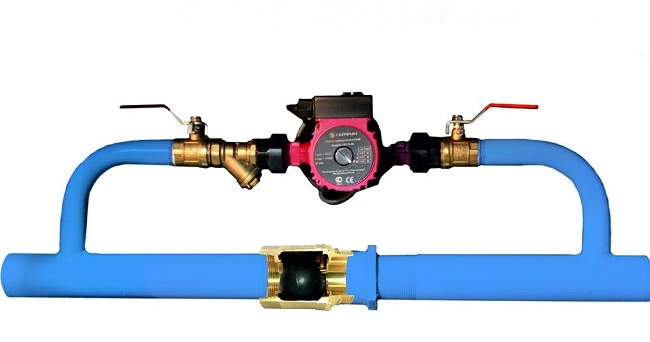

A bypass is a separate unit for installing a circulating pump with a loop bypass and valves for maintenance.

The bypass assembly provides several convenient features.

- When the ball valves are shut off, the supercharger can be removed without draining the entire system in order to repair the circulation pump or replace it.

- The system is powered without power.

- It is possible to carry out the initial start of heating without the participation of the circulation pump.

- It is easy to organize the structure of protection of the pump from impurities entering its turbine by installing a coarse filter or mesh type unit.

Water heating scheme of a private house can use as a bypass with manual or automatic control.In the latter case, in the loop bypass circulation pump mounted check valve.

When the circulation pump is operating, an overpressure is generated at the outlet of the check valve. The node overlaps the flow, providing an optimal pattern of movement of the coolant. When the power is turned off, water starts to move through the valve due to the natural gravitational component. This scheme does not require adjustment and adjustment, including during commissioning.

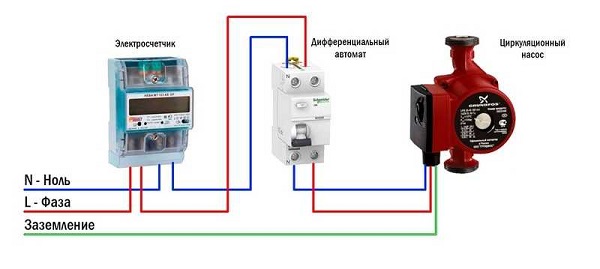

Connecting the pump to the power supply

Connection to the power supply network can be done in two ways.

Direct connection

The first is a standard, is a direct Connect the power cable to the outlet with the desired type of voltage. Wherein:

- choose a wire with a cross section of at least 2 square meters;

- conductors should be stranded to reduce the likelihood of fractures when bending;

- connection must be made using ground wire.

The specific cross-section of the conductors should be selected based on the recommendations of the manufacturer and the rated power of the pump. The socket in which the device is connected should be located as close as possible to the installation point, it is recommended to install emergency shutdown devices between it and the RCD pump.

It is recommended to connect the grounding wire from the socket, the general structure of the power grid. If this cannot be done due to the outdated type of wiring, the pump is allowed to be connected to an external circuit.

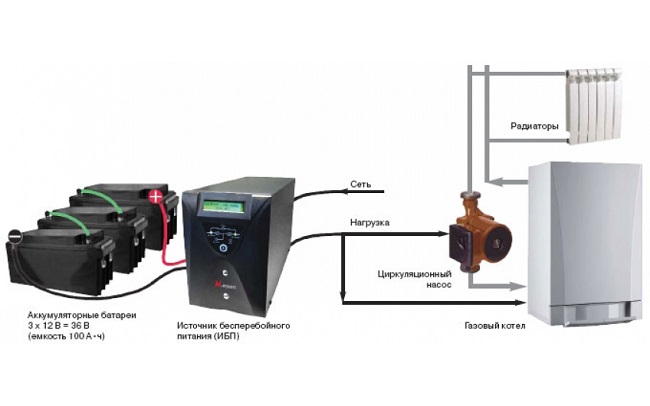

UPS application

During the operation of the supercharger, especially under load, there may be power failures, cases of its termination, changes in the input voltage parameters. This may adversely affect the service life of the device, its effectiveness, lead to breakdowns. Therefore, if possible, you should use a wiring diagram. through uninterruptible power supply.

When choosing a model of uninterruptible power supply carry out a simple calculation. The basic conditions include the power of the circulating pump and the time during which its operation must be maintained. According to the results of the calculation choose the battery capacity or UPS model. Many manufacturers of such equipment on their official resources offer charts and tables that make it easy to determine the best option for a power source.

Adjustment and start to work

Commissioning after the installation of the circulating pump is not difficult, but must be carried out in a specific order.

- The pump is mounted in the bypass or crashes into the return pipe.

- The device is connected to the mains.

- The heating system is filled with water.

- Air plugs are removed by opening the valves on specially made taps or Mayevsky taps installed on radiators.

- The air is removed from the casing of the circulating pump by opening the valve, unscrewing the screw on the lid of the device.

As soon as water starts to leave the special drainage of the pump, the device is ready for operation. After that, it is enough to start the heating boiler, check on the passport, what speed it is better to turn on at the heating pump, set the optimum mode and adjust the pressure parameters in the system in the process of heating the heat carrier.

Possible malfunctions of circulation pumps

Circulation pump - a fairly simple device. Its serious damage lies in the wear of the turbine wheel, the physical damage to the elements or the failure of the electrical circuit. Some malfunctions of the heating pump can be fixed by hand. For this device need dismantle and disassemble. The order of action is the following.

- Turn off power to the equipment.

- If the pump is installed in the bypass or there are taps on both sides - the coolant supply is shut off, the device is removed from the installation point.

- With long-term repair - you should install a spare pump.

When disassembling the circulation pump, you can access its main functional parts:

The pump is very buzzing, but there is no circulation of coolant

Such a malfunction occurs long equipment downtime. Sealing devices, bearings are deprived of grease, dense mineral deposits are formed. To start the pump is required to disassemble according to the manufacturer's instructions. The case, the electric drive is removed. Using a screwdriver or any clamping device, rotate the rotor and achieve its relatively free rotation. After that, the pump is installed on a regular place and turned on.

The device is very noisy when working

The reason for the excessive noise is trash ingress in the area of the motor shaft and the turbine wheel unit. The problem is eliminated by complete disassembly and cleaning of the device.

Pump does not turn on

There may be several reasons for the launch failure. The most common is power failure You should check the power cable (disconnecting the circuit breakers or pulling the plug out of the socket) for fractures, damages, and test the power supply voltage.

Another reason for launch failure is protection operation. To eliminate the problem, replace the fuses or other elements provided by the manufacturer. Before starting the pump, carefully check the status and parameters of the power supply network, make sure that the other systems connected to the supercharger are working properly.

The device starts and stops working after a short period of time.

The reason for the automatic shutdown is in overload. This is caused by scale on the parts of the wet rotor. To restore normal operation of the pump should be disassembled, remove mineral deposits using special tools.

Strong noise, vibration, heat

The reasons for the abrupt changes in sound and other operating parameters are air in the circulating pump. This problem may be caused by improper commissioning or by exceeding the minimum cavitation limit. Troubleshooting is made by adjusting the parameters of the heating system. Air plugs are removed from the pipes; a similar operation is performed by a valve on the upper part of the pump casing.

Constant, increased vibration

The cause of excess vibration may be bearing wear. These structural elements have a limited service life, even with ideal coolant parameters. The recommended interval for replacing bearings in circulation pumps is necessarily indicated in the passport of a specific model.

It is worth remembering that you can pull a bearing pressed into the bore by using a special puller. Re-installation at home is made with a wooden mallet.The new bearing is placed on the mounting bore and clogged with light, precise strokes.

Insufficient pressure

Properly installed, working circulation pump in some cases is not able to provide sufficient pressure. The reason may be Incorrect rotation speed setting what is often observed at high viscosity of the heat carrier or excessive length of pipelines. If there is such a possibility - the device is regulated, in case of a wrong choice of the model, it is replaced.

At three-phase pumps The cause of insufficient pressure may be in the wrong wiring. Therefore, the first phase of troubleshooting should be to check the phasing, the condition of the neutral wire, the voltage of the grid.

It is always necessary to remember that the circulating pump does not reach the user immediately after production. Therefore, knowing how to disassemble and clean the device, as well as its component parts, is useful. For example, such information will easily help to cope with the case when the trip occurs due to oxidation of the contacts of the fuses. The operation of partial disassembly and stripping in this case can be performed even without dismantling the device.

Important! If simple troubleshooting methods do not help, you should seek professional help. To determine the gap (degree of wear of the turbine wheel) between the impeller and the housing may require special tools. The same applies to the evaluation of the parameters of the motor windings. In some cases, complex, professional repairs may be required.

Conclusion

In order not to encounter malfunctions of the heating system, do not freeze, do not spend money and time to make changes to the harness, you should not save on the design and proper organization of the installation sites of the circulation pumps. Bypasses equipped with shut-off valves, filters, check valves, the right choice of the installation point will help simplify the setting of the heating, provide automatic control, guarantee optimal working conditions of the equipment and significantly increase its reliability and service life.

/rating_off.png)