How to remove the main malfunctions of the submersible pump

Submersible pumps have to work in difficult conditions. They are constantly exposed to water, vibration, low temperature, abrasive particles, etc. But despite the fact that the units are made of parts with a large margin of safety, in them over time there are various faults. In order to repair the water pumps with your own hands, you need to familiarize yourself with the main symptoms indicating these or other equipment failures.

Content

Main malfunctions of submersible pumps

If a submersible pump fails, it is not always necessary to remove it from the well for inspection. This recommendation only applies to pumping stations in which pressure switch installed. It is because of it that the device may not turn on, not turn off, or create bad water pressure. Therefore, it is first checked that the pressure sensor works, and after that, if necessary, the pump is removed from the well.

Important! In the case of submersible pumps that operate without accumulators, they should always be removed from the mine when any signs of breakage appear.

Failures of the water pump will be easier to diagnose if you first become familiar with the most common breakdowns of this unit.

Pump not working

The reasons for the pump not working may be as follows.

- Electrical protection tripped. In this case, turn off the machine from the network and turn on the machine again.If he is knocked out again, the problem should be sought not in the pumping equipment. But with the automatic switching on of the machine, the pump is no longer included in the network, you must first find the reason for which the protection worked.

- Blown fuses. If, after replacing, they fail again, you need to look for the cause in the power cable of the unit or in the place where it is connected to the power grid.

- Cable damage has occurred.under water. Remove the device and check the cord.

- The protection of the pump against starting “dry” has been triggered.". Before starting the machine, make sure that it is immersed in the liquid to the required depth.

Also, the reason that the device does not turn on may be due to the incorrect operation of the pressure switch installed in the pumping station. It is necessary to adjust the starting pressure of the pump motor.

The pump works, but does not pump

There can be several reasons for the device not pumping water.

- Shut off valve closed. Turn off the machine and slowly open the tap. In the future, you should not start the pumping equipment with the valve closed, otherwise it will fail.

- The water level in the well dropped below the pump. It is necessary to calculate the dynamic water level and immerse the device to the required depth.

- Check valve stuck. In this case, you need to disassemble the valve and clean it, if necessary, replace it with a new one.

- Intake filter clogged. To clean the filter, the hydraulic machine is removed and cleaning and rinsing of the filter screen is carried out.

Slow machine performance

Also, a decrease in performance causes:

- partial clogging of valves and valves installed in the water supply system;

- partially clogged riser apparatus;

- pipeline depressurization;

- improper adjustment of the pressure switch (applies to pumping stations).

Frequent on and off of the device

This problem occurs if the submersible pump works together with the hydroaccumulator. In this case, frequent starts and stops of the unit can be provoked by the following factors:

- in the hydraulic tank there was a decrease in pressure below the minimum (by default it should be 1.5 bar);

- ruptured rubber pear or diaphragm in the tank;

- pressure switch not working properly.

Water is pulsed

If you notice that tap water is not flowing in a steady stream, then this is a sign of a decrease in the water level in the well below the dynamic. It is necessary to lower the pump deeper if the distance to the bottom of the shaft allows this.

A buzz is heard, but the water does not swing

If the pump is buzzing and there is no pumping of water from the well, then there may be several reasons:

- “gluing” of the impeller of the apparatus with its case occurred due to long-term storage of the device without water;

- engine start capacitor faulty;

- voltage down the network;

- wedged the impeller of the pump because of dirt gathered in the housing of the apparatus.

The unit does not turn off

If the automation does not work, the pump will work without stopping, even if excessive pressure is created in the hydraulic tank (as seen from the pressure gauge). All the fault is pressure switchbroken or improperly adjusted.

Nuances of breakdowns depending on the brand of pump

When operating pumps from different manufacturers, it was noted that some brands of devices often undergo the same breakdowns. From this it follows that these models of units have their own distinctive features in terms of the appearance of faults.

Aquarius

Pumps "Aquarius" have predisposition to overheating, especially if working in wells of shallow depth. If a cheap model breaks, its repair costs about 50% of the cost of a new device. If a device fails, it is easier to throw it away than to repair it.

Grundfos

Most models of this manufacturer have valve system. Also around the engine there is a special insulation. Sometimes failures in the pump are due to the failure of the listed parts. Since the thermal insulation gasket is located around the engine, it will need to be removed from the housing for repairs.

Kid

Devices “Kid” are products of domestic manufacturers. The cost of repairing units of this brand is not high, and most of the failures are eliminated by the owners of the devices themselves. The main breakdown often encountered in this pump is occurrence of strong noise during the work of a hydraulic machine without pumping out of liquid. This behavior means that there was a rupture of the central axis holding the anchor and the membrane.

Jilex

The engine in the pumps of the vortex and rotary type “Dzhileks” is oil filled. Therefore, frequent breakdown of these units is engine oil outflow. You can add it only in the service center.

Important! Many on the Internet are advised to use transformer oil or regular glycerin instead of the original oil filler. It is not recommended to do this, of course, unless you set a goal for yourself to spoil the technique in an unusual way.

Trickle

It is believed that the work of drainage pumps “Streamlet” can continue without interruption for 7 hours or more. This is explained by the peculiarity of their design that meets all standards of European standards. But despite this, the device overheating as well as pumps from other manufacturers. Therefore, it is recommended after every 2-3 hours of operation of the device to give him time to “rest”.

Marquis (Marcus)

The owners of the pump for the well “Marcus” sometimes notice that the device is turned on only after a slight blow, either through the pipe to it or after the blow to the hydraulic machine itself.This fault is due to “souring ”impellerwhich should be cleaned, having disassembled the unit.

How to disassemble the unit to diagnose damage

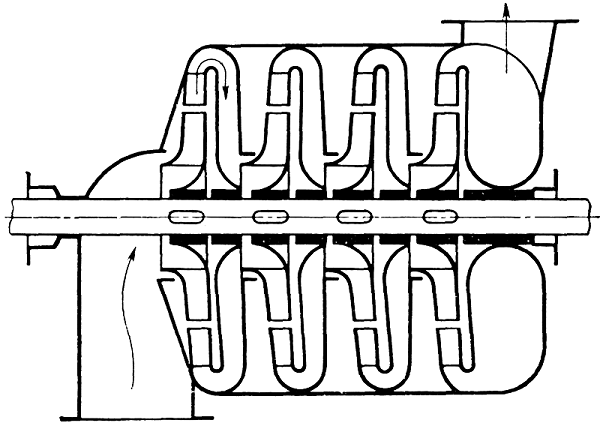

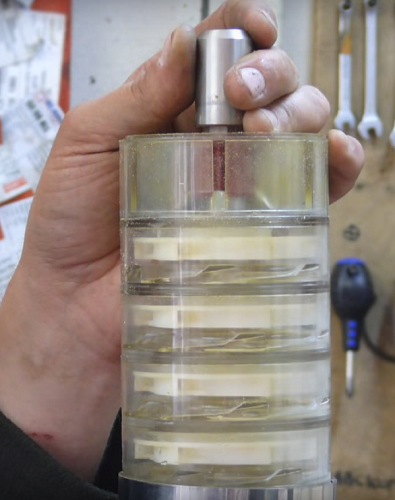

If the pump breaks, requiring replacement of parts located inside its body, the unit will need to be disassembled. Submersible pump consists of a compartment for the engine and a compartment with one or more impellers, the purpose of which is to capture water. Below is a diagram of the device of the part of the centrifugal pump, where the impellers are installed.

As can be seen from the figure, the impeller is mounted on the shaft of the unit. The more of them, the higher the pressure created by the pump. In the second compartment of the hydraulic machine is located rotary engine. It is in a sealed enclosure, and to open it, you need to know some of the nuances.

So, to move from theory to practice and disassemble the pump, follow these steps (depending on the manufacturer, the design of the unit may vary).

- Loosen the 2 screws that hold the mesh of the machine.

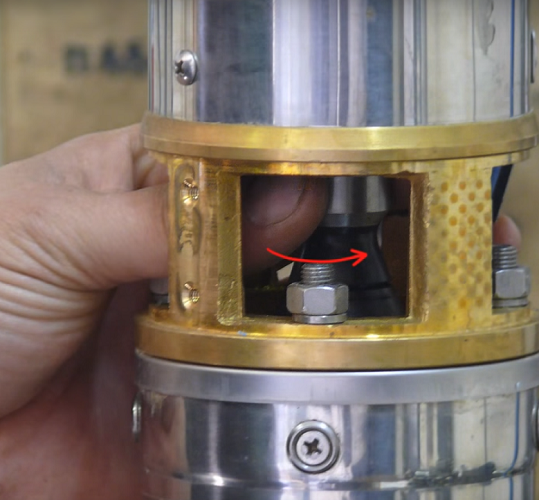

- Remove the net and rotate the motor shaft by hand. If it does not turn, then the problem may be either in the engine compartment or in the pump part of the apparatus.

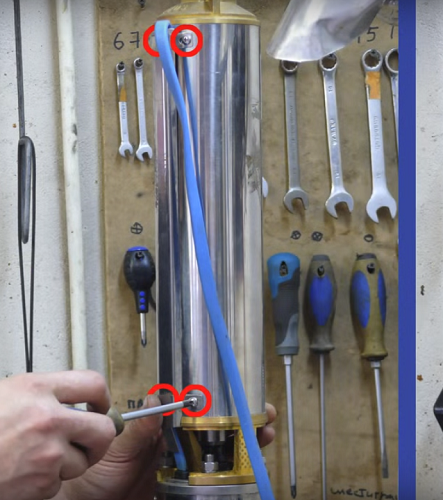

- First you need to disassemble the pump part of the device. Unscrew the 4 screws holding the channel of the power cable and disconnect it from the unit case.

- Next, unscrew the 4 nuts holding the pump flange.

- After unscrewing the fasteners, separate the pump part of the device from the engine. At this stage, you can determine in which section the jamming occurred. If the shaft of the pump compartment does not rotate, then it is necessary to disassemble this assembly.

- Twist the entire fastener holding the bottom flange of the pump part of the unit.

- In the fitting located at the top of the block, you need to twist the adapter, which will help keep the thread from damage.

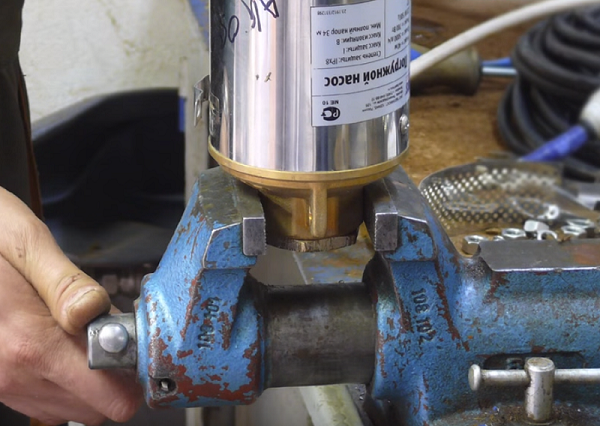

- Secure the pump in a vise.

- Having picked up the suitable tool, turn off the bottom flange.

- Now you can pull out the impeller unit and inspect it for troubleshooting.

- Next, you should check the support shaft for wear or play.

- To replace (if necessary) impellers, it is necessary to fix the shaft in a vice and unscrew the upper nut.

- At the next stage, the blocks are removed, washed and, if necessary, replaced with new ones.

- The assembly of the pump part of the apparatus is performed in the reverse order.

- To disassemble the motor, it must also be fixed in a vice.

- Next, you should remove the plastic protection of the flange, unscrewing the fasteners.

- Remove the retaining ring holding the lid using the pliers.

- Remove the cover using a slotted screwdriver.

- Remove the rubber membrane from the housing.

- Remove the condenser.

- At this stage, you can check the level of oil, its quality, identify the cause of jamming, etc. Going to engine block in reverse order.

Replacing and repairing defective parts

Now that you know how to disassemble the hydraulic machine, you can try to repair the submersible pump with your own hands.

Impeller

Mostly impeller locking occurs due to sandblasting them or because of the formation of dirt on them. In addition, the impellers can be soldered together when a high temperature occurs in the unit when the pump is idling (dry running). To repair this section of the unit it is necessary to remove the impeller (impeller) and remove the accumulated dirt. If the impellers are damaged, you will need to replace them with new ones.

Engine

It is not recommended to carry out self-repair of the pump engine, since for diagnosing this node and subsequent repair it is required to have special knowledge and have the necessary equipment.

In some models of pumps, in order to remove the engine, it will be necessary to press it out using special equipment. Replacing the gland and bearing also held in a service center.

Capacitor

If a engine buzzing and not startingthen you should check the capacitor. It is located in the pump unit in which the motor is installed.

But when the shaft with the impellers rotates without problems, then to remove the hum in the water pump, you should disconnect the condenser and change it to a new one. Of course, better check this item with a multimeterSince similar symptoms can be caused by a short circuit in the motor windings.

Butter

The engine of the water pump is in a special glass filled with oil, and according to its condition, some breakdowns in the electric motor unit can be identified.

- The oil has a characteristic, unpleasant smell.. This means that the engine is still in working condition, but it worked with large overloads.

- Cloudy oil - Water has entered the engine housing due to a crack in the housing or a failure of the gland (cuff) failure.

- Black oil with an unpleasant smell. In this case, we can say with great certainty that the varnish was burning on the engine coils.

Important! Normally, the oil should be clear. Its quantity is determined by the model of the unit. On average, the volume of oil poured into the chamber is at 0.5 l.

If, when opening the engine, the above-mentioned changes in the quality of oil were noticed, then first you need to repair this unit, and after that fill in a new lubricant.

What is the phenomenon of cavitation

Everyone knows that water is dissolved some gas. When a fluid moves at a certain speed, rarefaction zones sometimes form in it. In these zones of reduced pressure, gas bubbles begin to precipitate from the water. After the bubbles hit the high pressure zone, they collapse. This process occurs with the release of large amounts of energy, from which the impeller and the cochlea of the pump are destroyed.The following photo shows the impeller destroyed by cavitation.

The energy of the collapsing bubbles is able to create shock wavescausing vibrations. It extends throughout the unit and affects not only the impeller, but also the bearings, shaft and seals, from which these parts quickly become unusable.

The cavitation effect can most often be observed in pumping stations that work on the suction. In such systems, the impeller creates a vacuum, due to which water rises through a hose from a well. But if at the entrance to the pump there is a lack of liquid, then in the area of the impeller an excessive vacuum occurs, provoking the occurrence of cavitation.

Important! The most obvious signs of cavitation are the vibrations of the pipes and the pump itself, as well as increased noise during its operation. If you do not take any measures to eliminate this process, then it can completely destroy the station.

To prevent cavitation in the pumps, follow the rule: there must be more water at the inlet than at the outlet. There are several ways to achieve this:

- move the device a little closer to the source;

- You can increase the diameter of the suction pipe (hose);

- to reduce the resistance at the suction site, you can replace the suction pipe with a pipe of a smoother material;

- if there are many turns on the suction pipe, then, if possible, reduce their number;

- it is desirable that all bends have large turning radii.

/rating_off.png)