How to choose a piston compressor

Compressors are units that produce compressed air or gas to supply them with various industrial equipment, machinery, tools, etc. These units may differ structurally, have different power and performance. Despite the variety of types of units for air compression, reciprocating compressors are still the most popular.

Content

What are the advantages of reciprocating compressors

The advantages of reciprocating compressors over other types of similar equipment are as follows.

- Low unit cost, which primarily attracts the consumer. Despite affordable prices for piston units, their technical characteristics are not inferior to more expensive equipment designed to compress air.

- Piston air compressor can use to compress aggressive gases. For example, the use of ammonia piston compressors in refrigeration units of refrigerated wagons is widely used.

- Reasonably inexpensive repair. Although rarely required, all parts for it can be purchased at a low cost. In addition, almost all elements of the compressor can be repaired.

- The possibility of short-term operation of the device. That is, intermittent operation of the unit eliminates the need for its uninterrupted use.

- Ease of management and configuration, which simplifies and accelerates the process of working with pneumatic equipment. In addition, piston units are easy to manufacture, which affects their final cost.

The efficiency of a piston compressor is in the region of 60-70%, and this figure is not as high as that of screw machines (efficiency = 99%). But still, the use of piston units is more efficient if low productivity is required (up to 200 l / min) with a pressure of 20-30 atmospheres and more. But you should know that the regulation of performance on reciprocating compressors is a rather complicated task.

Types of piston type compressors

In the market of compressor equipment, a large number of modifications of piston-type devices are presented. There are models of both multistage and single-stage, double-suction and one-sided, glandless, gland, and others. But, basically, the classification of reciprocating compressors is carried out according to design features, the number of compression stages, working pressure and type of drive.

Piston machines are:

- single and double action (clearanceless and crosshead);

- oil and oil-free;

- angular, horizontal and vertical;

- single stage and multistage.

Also devices for air compression differ in the type of drive:

- belt drive;

- direct drive (coax).

Rimless and crosshead units

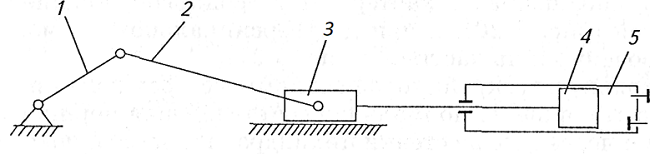

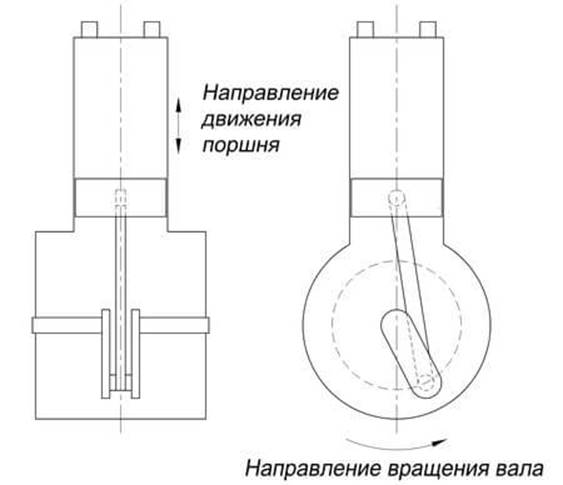

Crosshead translated from German - slider. This part of the crank mechanism is designed to connect between the connecting rod and the piston. The figure below shows the crosshead compressor.

The crosshead view of the apparatus consists of a crank (1), a connecting rod (2), a crosshead (3), a piston (4) and a cylinder (5) with installed valves.

Crosshead principle consists in movements along longitudinal guides, due to which perpendicular loads are removed from the piston. The use of the slider significantly increases the life of the piston and cylinder.

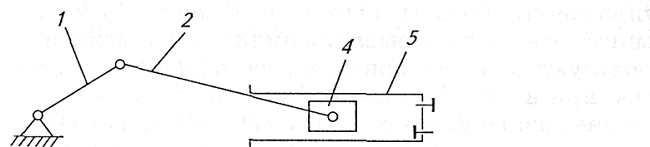

The following figure shows the device of a borderless apparatus in which the connecting rod (2) is connected to the piston (4) directly.

Oil and oil free

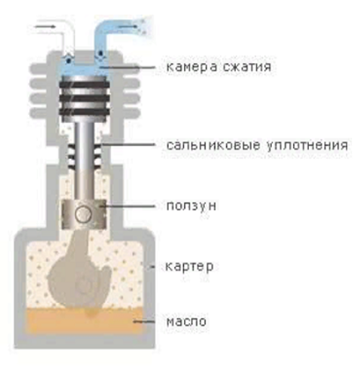

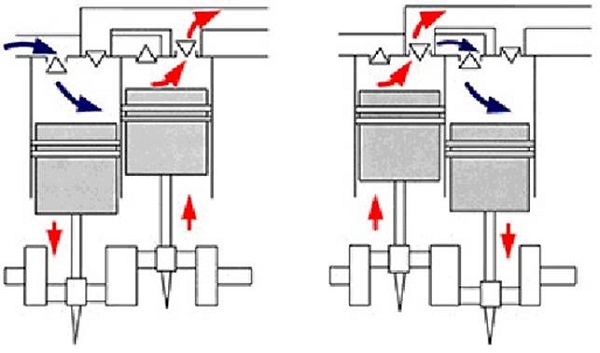

When a piston interacts with a cylinder, friction inevitably arises, which causes not only wear and strong heating of these parts, but also overheating of the connecting rod with the crankshaft. To reduce the negative effects of friction are applied lubricants. The following figure shows how a crosshead oil compressor works.

Oil is poured into the crankcase, lubricates the moving elements of the compressor and acts as a coolant.

In oil-free devices, lubrication is not used, and the piston moves in a “dry” cylinder. To reduce friction, all friction elements of the piston group (cylinder and piston) are made of low friction materials.

Corner, horizontal and vertical devices

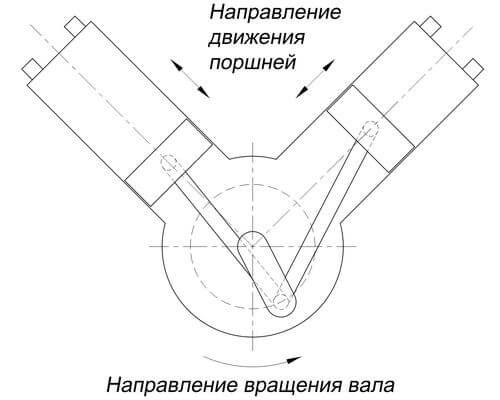

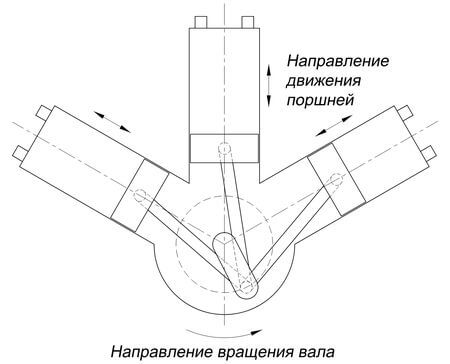

According to the principle of the location of the cylinders, the apparatus is divided into angular, horizontal and vertical.

With angular placement of cylinders, they can be located at a right angle, that is, one row is installed horizontally, and the second - vertically.

Cylinders can also be located V-shaped or W-shaped.

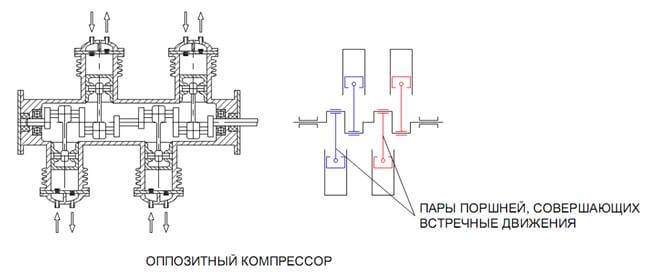

On horizontal units Cylinders (cylinder) are placed either on both sides of the crank, or on one.

Also to the horizontal units can be attributed box compressors. These are, as a rule, aggregates of medium or high productivity.

Important! The principle of operation of boxer units is slightly different from the operation of other piston compressors. The difference lies in the opposite movement of the pistons located on both sides of the crank.

On vertical machines cylinders are placed vertically.Depending on the required pressure and the scope of the units, one or more cylinders can be mounted on them.

Single stage and multistage

Piston devices for air compression are distinguished into single-stage, two-stage and multi-stage.

Units with one compression stage are the progenitors of devices with several steps. They are distinguished by a simple principle of operation: the air in the cylinder is compressed in one direction with the help of a piston, which is driven either by a direct or belt drive.

Despite one compression stage, the units have a number of positive qualities:

- low-power engine required;

- simple connection;

- compact size;

- Ease of Management;

- ease of repair and maintenance.

On a note! Compressors with one compression stage are most popular both among individuals and among large companies.

Devices with two stages of compression are considered to be the best in terms of efficiency and power of the equipment they serve. Two-stage vehicles, as the name implies, have 2 pistons. Therefore, the air is compressed in 2 stages:

- in the first stage, the air is compressed and forced into cooling in order to expand its compression range;

- At the second stage, the maximum air compression occurs.

Thanks to two stages of compression, an even distribution of loads occurs, which increases the service life of the unit and increases efficiency, since significant savings are achieved in power that is spent on compression.

Multi-stage installations for air compression - These are, as a rule, industrial units. They have more than two stages of compression, have heat jackets that remove excess heat, and are distinguished by their large size and weight. Multistage compressor units with piston compressors allow compressing air (gas) under high pressure and producing it in large volumes. It does not require the use of high power.

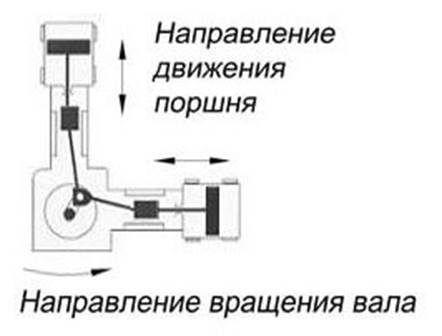

Devices with direct and belt drive

Piston devices used for air compression can be equipped with two types of drive: direct (coaxial) and belt.

In coaxial units The electric motor is connected to the crankshaft of the piston unit of the apparatus using a coupling (see the figure above).Devices with direct drive are divided into oil and oil-free. The latter are used in areas where the quality (purity) of air is of particular importance (air must not have impurities of lubricant and moisture).

In belt driven machines The crankshaft of the piston unit is connected to the engine shaft via a belt drive (see figure above). The belt drive ensures high performance of the equipment and its continuous operation (the devices can work without interruption for several hours).

Main characteristics of piston units

The main characteristics of piston units that should be taken into account when choosing are performance, operating pressure, air quality and noise.

Performance

The performance of a piston compressor in its passport is denoted in m3/ min or l / min Since piston units operate in on-off modewhich means using 50% of the time for work and 50% for “rest”, then when calculating a piston compressor, it is necessary to take into account its shutdown time. For example, if it is known that a pneumatic equipment or tool requires a flow rate of 500 l / min., Then the unit, taking into account the pause, should produce 1000 l / min.

Power

This parameter is measured in kW and relates to engine power. Typically piston compressor power not specifically calculated. This is because it will be sufficient to calculate only the performance of the unit. Having picked up the device with the necessary performance and looking in the passport to it, it is easy to find out the engine power of this device.

On a note! Basically, information about the power of the device is useful when laying the electrical cable to which the equipment will be connected. The cable must have a wire cross-section corresponding to the power of the apparatus for compressing air.

Operating pressure

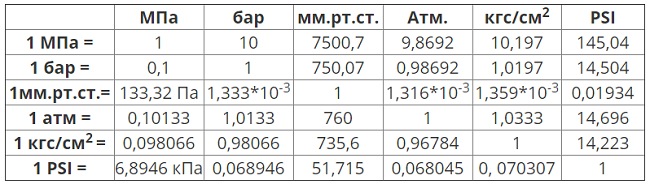

Pressure is measured in units such as bar, Pascal (Pa), atmosphere (atm.), A millimeter of mercury (mm Hg) or kilogram-force per square meter. centimeter (kgf / cm2). For English-speaking countries, it is common to measure pressure in pounds per square inch (PSI).

The relationship between units is shown in the table below.

Working pressure is, one may say, the main characteristic of compressor operation. The efficiency of the pneumatic tool or equipment using compressed air depends on this parameter. Any pneumatic tool can only work properly at a certain pressure in the system. This indicator is indicated in those. documentation for the instrument or other equipment using compressed air.

Air quality

Such a characteristic of a piston compressor as air quality is especially important for various industries and not only where it is necessary to use compressed air without the slightest impurities of moisture and oil. For example, the presence of oil or moisture in the air during painting works can completely spoil the end result. Paint or varnish will not go smoothly, with the formation of bubbles, which further will cause delamination of the coating.

Noise

The noise level is measured in dB. Piston type air compression equipment is the noisiest among devices of similar action. For example, devices with a belt drive are capable of producing noise exceeding 100 dB. Devices with a coaxial drive are quieter and “noisy” in the range of 80 to 90 dB.But the quietest units are oil-free devices, which, due to their design, have a noise level of about 70 dB.

Some compressor manufacturers use noise protection covers, reducing noise from the working unit to a more comfortable level for a person. The following photo shows the device with noise protection casing.

The noise shield is installed on the piston unit, and sometimes on the engine, thereby reducing the noise of the unit as a whole. Basically, this method of noise protection is used on oil compressors with a belt drive.

Remeza also developed original piston units to combat noise levels.

Twin-cilinder blocks allow you to achieve a noise level of 65 dB. Compressors of this type already belong to low-noise units.

Overview of 5 Popular Piston Compressor Models

The domestic market is overflowed with products of various companies competing in the field of compressor equipment. Among them are both leaders and outsiders. Below is the ranking of the best air piston compressors that have gained the most popularity among consumers.

ELAND Wind 24B-1CO

The homeland of the compressor is Sweden.ELAND has a dynamic growth and supplies its products to 50 countries of the world. The company's management is aimed at long-term cooperation with its partners, and therefore prefers to produce high-quality equipment.

The ELAND Wind 24B-1CO unit is a piston oil compressor. The compressor engine has a power of 1.5 kW and is connected to the shaft of the piston unit through coaxial (direct) drive.

The receiver of the device has a capacity of 24 liters. The maximum pressure created by the device is 8 bar. The cost of the compressor is about 6200 rubles.

FUBAG OL 195/24 CM1,5

This unit is a product of the German manufacturer, which has 40 years of experience in the production of professional equipment for repair and construction. Products of the FUBAG brand won not only European markets, but also supplied to virtually all countries of the world.

Compressor FUBAG OL 195/24 CM1,5 - piston unit operating on 220 V. This unit is oil free and is able to create pressure up to 8 bar.

The device has a direct drive and a 1.1 kW engine. Also, the compressor has a receiver (24 l.), 1 cylinder and 1 compression stage. The cost of this unit is low and varies between 6500-7000 rubles.

Interskol KV-240/25

This is a compressor from a Russian manufacturer that produces a professional power tool. The company's products Interskol is in the top of the popularity in Russia for 15 years. And this is due to the fact that all the products of this company have affordable prices and high quality.

The piston compressor with the direct drive Interskol KV-240/25 is single cylinder unit with a receiver on 25 l.

The device is equipped with a 1.8 kW engine. The device can develop pressure up to 8 bar. Device productivity - 240 l / min. The cost of the compressor ranges from 8900 rubles.

DENZEL PC 2 / 50-350

DENZEL is a German company that produces professional equipment and electrical equipment. The company focuses on the most demanding consumer, so home and professional craftsmen prefer products under the DENZEL brand.

The piston oil compressor DENZEL PC 2 / 50-350 has a direct drive and a 50 l receiver. Also on this unit installed 2 cylinder.

Engine power at the unit is 2.2 kW, and the maximum pressure is 8 bar. The price of the compressor DENZEL PC 2 / 50-350 is in the range of 1169-1200 rubles.Economical option for home and garage.

JAS-1203 II

Finishes review airbrush compressor JAS-1203 II. Jas is a Russian trademark distributing products from China. The specialization of this brand is equipment for aerography artists.

On a note! The Jas 1203 II mini-compressor is the most popular device among artists engaged in airbrushing.

This compact unit is ultra-reliable, low-noise, when compared to conventional compressors, and has an engine power of 150 watts. The device is capable of producing 23 l / min, which is enough for an airbrush.

The unit is equipped with a 3 liter receiver, a pressure regulator and a moisture separator. The device easily maintains the working pressure in the range up to 4 kg / cm2. The device weighs 5 kg and produces a noise of about 42 dB. Buy a mini-compressor can be priced at 5800-6000 rubles.

/rating_off.png)