Causes of pumping station malfunctions and their own removal

The pumping station is the heart of the summer house water supply system or private house. This simple, but functional, device capable of providing good pressure can be purchased at retail by choosing the model that is optimal in its characteristics. Pump stations, when properly installed, are reliable, stable, and do not require periodic maintenance. However, failures in their work inevitably occur over time. Know the malfunction of the pumping station and how to eliminate them is necessary for each owner of such equipment. In some cases, it is quite possible to carry out repairs yourself.

Content

- 1 What is a pumping station

- 2 Automation and safety equipment

- 3 Malfunctions and methods of their elimination

- 4 What to do if the pumping station froze

- 5 Tips for trouble free operation

What is a pumping station

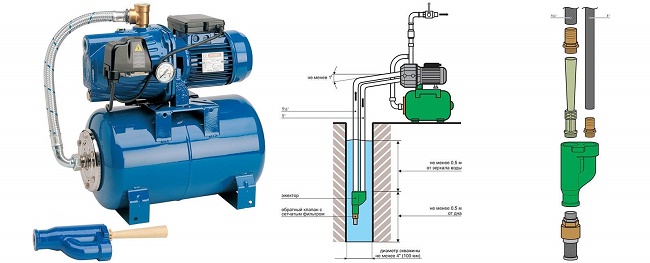

A pumping station is a complex of a pump, a hydroaccumulator-compensator and control automation. Such a system is capable of:

- supply water to the network at home and maintain the required level of pressure in it;

- to provide adjustment of the pressure to supply water to the second floor or to meet the maximum level of consumption;

- protect the piping system from water hammer that could lead to the destruction of parts of the water supply system;

- keep a certain amount of liquid inside the accumulator, which is useful when the power supply is turned off or when the water source is exhausted.

The specific engineering solution of the pumping station may be different. For example, for deep wells apply submersible pump. When taking water from a shallow well is used surface blower. The volume of the hydroaccumulator may be different, depending on the consumption parameters calculated for a private house.

Automation and safety equipment

To understand how to quickly diagnose and troubleshoot, you need to know about the means of control of the pumping station and how it works.

- The reasons for the failure of the pump is dirt and mechanical suspensions. Therefore, the feed pipe must be installed coarse filter.

- To avoid problems when the station does not pump water - it is necessary to mount it on the supply pipe backstop valve. It will not allow water to escape back into the well and prevent air from entering the circuit.

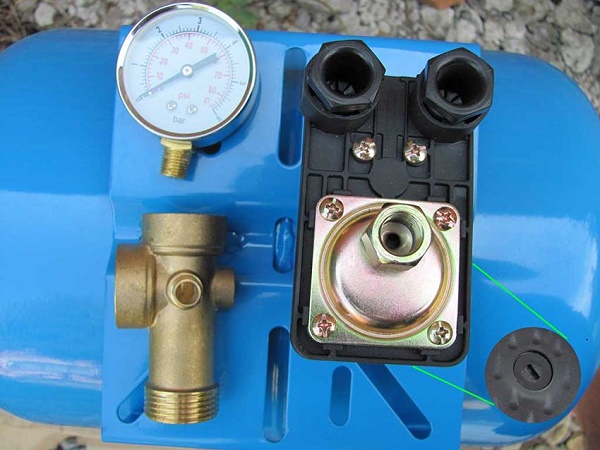

- Manometer - the main device for monitoring the operation of the station and the state of the water supply network. Installed on the outlet pipe, it shows pressure and allows for an instant assessment.

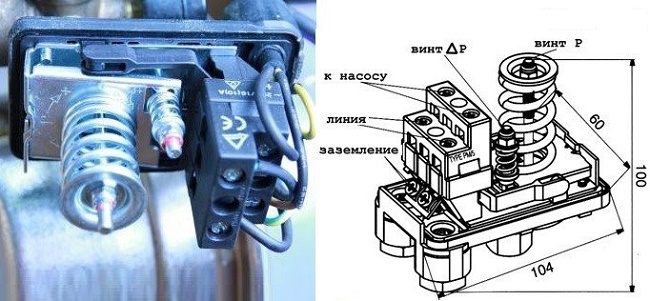

- Pressure settings are made corresponding relays. It is included in the list of hydroaccumulator units and is responsible for switching on and off the supercharger engine.

Everything works quite simply. At initial start-up, the pump pumps water into the hydraulic accumulator.Inside it is a membrane, a rubber pear. Being filled with water and expanding, it compresses the air in the tank. The sensor monitors the growing pressure. When the set level is reached, the relay shuts off the pump. The pressure gauge shows the pressure that is reached in the water supply. When a tap is opened inside the house, the water enters the network, picking up from the accumulator pear. When the pressure drops below the set limit, the relay activates the pump and the cycle repeats.

Malfunctions and methods of their elimination

Unfortunately, over time, the pumping station may start to work in abnormal mode. It is impossible to avoid this, since there are no eternal materials; oxidation and leakage processesIn addition, dirt accumulates in the plant nodes during operation. If the plumbing system began to work poorly, you should slowly check the condition of the pumping unit and eliminate shortcomings that can be handled by yourself.

Pump does not turn on

There may be several reasons for the pump not responding to start commands and not starting.

- Checked mains condition. The integrity of the power cable is assessed (there should be no insulation rubbing, fractures).

- Being tested line voltage. With a low pump does not work.

- Checked quality of connection of contact groups (sockets, operability of protective automats).

If the checks showed that everything is in order, and cleaning the contacts did not bring results, the problem may be pressure sensor operation: it does not work. The hydroaccumulator control unit partially disassembles, checks the state of the relay (contacts, springs), if necessary, parts are cleaned of corrosion and dirt.

If the pump does not start after the measures taken, the problem may be in the combustion of the windings. Such repairs at home will not succeed.

The engine buzzes but the pump does not start.

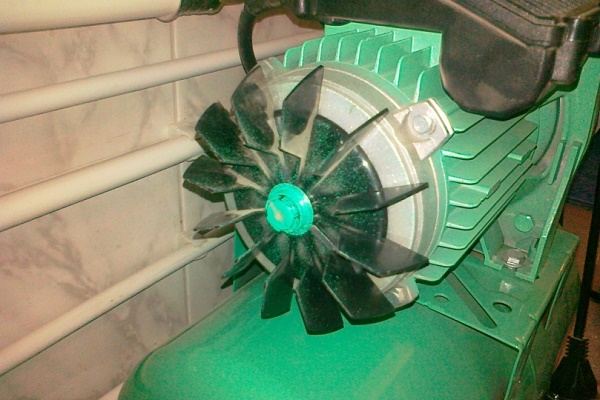

With long-term idle station, its owner may face a situation where, when turned on, the pump hums, but does not pump. The reason for sticking the impeller of the turbine, sticking to the body. This issue is resolved as follows.

- The station is disconnected from the mains, it is necessary to block the inlet and outlet nozzles.

- With the help of drainage it is necessary to drain the water from the feed system.

- Partial disassembly of the pumping station.

- The impeller is rotated manually or removed.

- It is recommended to remove the impeller from the pumping station in order to thoroughly clean the inner surfaces of the housing and the part itself.

Pumping station jerky, does not hold pressure

With frequent switching on and off of the pump (jerky), and also when the station does not hold pressure, it is worth looking for the source of the problem in the accumulator node and piping. There can be several reasons:

- seal failure;

- low air pressure in the body of the accumulator;

- water leaving the system through a check valve;

- leakage when the rubber element is damaged.

The last problem listed is the easiest to diagnose. If the loosening of the spool or nipple outlet pressure control on the hydroaccumulator from it is water, not air - then you need to change the pear. With long-term operation, rubber (including due to the chemical composition of water and impurities in it) loses its flexibility and can crack.

How exactly is the replacement of the pear, it is necessary to learn from the documentation for a particular model of the accumulator. Separate manufacturers can use different sealing systems, provide a unique scheme for the installation of elements and membrane design.

Control of parameters of the hydroaccumulator

If everything is in order with the pear, and when the control outlet opens, air goes out of it, you need to check the accuracy of the parameters of the accumulator. Back pressure in the tank body checked by pressure gauge. It is attached to the spool or nipple outlet hydraulic tank. In the case when there is no pressure at 1.5 - 1.8 atm, it must be adjusted. Typically, the value indicated by the gauge is smaller. Air must be pumped using a compressor or bicycle pump directly through a control outlet.

Malfunctioning check valve

Another reason for the pressure drop and the station jerky operation is a violation of the functions of a check valve installed on the supply pipe. This node required to be cleaned, check its performance. If it is impossible to repair, it is necessary to do a replacement, after which it is necessary to re-perform all commissioning works for the station.

Leaks and Leaks

The last reason for jerk work is leakage and leakage. To ensure no water leaks, check all connections of the inlet and waste pipes. If no faults are detected, then the problem is in the accumulator and air leakage. Checking the tightness of the case is carried out as follows:

- soap solution gets divorced;

- a soap emulsion is applied to the problem points of the structure (lines of welding of the installation elements, to places with abrasions, signs of corrosion);

- Leakage points are determined.

The pump does not build pressure or does not shut off automatically.

Problems of pressure mismatch with specified parameters and the absence of shutdown are always connected with the operation of the hydraulic tank control relay. Salts are deposited on the elements of this site, its contact groups may oxidize over time.

If the pump does not build up pressure, it shuts off automatically - the relay can be re-adjustedwithout having the skills of parsing and cleaning contacts. This is done by going over the position of the regulator and monitoring the pressure readings according to the pressure gauge installed at the station output. In the case when the supercharger does not shut down for a long time, it is recommended replace relay. If this cannot be done, the station should be disconnected from the network, partially disassembled the control unit and thoroughly clean all elements of the sensor structure. It is recommended to pay special attention to corrosion traces. You can get rid of them with the help of special tools.

Important! To operate a station that does not turn off automatically is highly undesirable. This can lead to a very rapid failure of its functional elements or rapid breakdown of the pump engine, turbine parts.

The reason that the pressure drops, or the pump is often turned on in systems with rising water from the depth with a surface blower, can be problems with the ejector. This node has a plastic diffuser, which is extremely negatively affected by impurities in the water. When it breaks, the ejector does not pump water, and the pump cannot cope with the task on its own. To check the status of the diffuser and other elements of the entire site must be disassembled. Repair is reduced to the replacement of broken parts or to thorough cleaning and reassembly.

The station does not pump water

The reason that the station stopped pumping water may be its banal absence in the supply pipe. First check is the intake hose immersed in a fluid source. Also evaluate the state of the filter at its end.

If everything is in order, check check valve status. Due to accumulated dirt, this node may not open and block water access to the station system. Minimal repair of the check valve consists in its disassembly and thorough cleaning. If individual elements of the structure are deformed or damaged, the unit must be replaced entirely.

The most difficult and troublesome breakdown - pump development. The impeller and housing wear during operation under the abrasive action of mechanical impurities in water. In this case, the maximum supply pressure drops, and with some critical indicators of wear - the pump stops pumping water.

Inspect the impeller, measure the gap between it and the body, assess the degree of wear only after disassembling the pump. If, during such an inspection, an excess of permissible parameters (given in the passport to the device) is found, the damaged parts of the mechanism should be replaced.

In the most difficult cases will have change bodythat under certain designs of the pump can be a big problem, requiring for its elimination skills, knowledge, money.

Air in the pumping station

Another reason that the pumping station does not supply water or does not turn on when the sensor prevents the idling - the presence of air in the supply line. To eliminate such a problem, it is required to provide a nozzle for forcing the system to be filled at the equipment installation stage. While the inlet is not filled with water - the station will not work. In some cases, you can use a simple technique: pull out the supply hose, lift its end above the point of installation of the pump and pour water into it manually.

What to do if the pumping station froze

As a conclusion, it is worth touching on the issue of resuscitation of a pumping station. Despite the clear instructions for operating the equipment only in a warm room, situations where the pumping station is frozen happen. Water can turn into ice:

- inside the underwater pipe to the house, on the border of soil freezing;

- in the supply pipes coming from the well or well;

- in the part of the pipeline immediately adjacent to the pump:

- in the most difficult cases - inside the pump mechanics.

If during the inspection of the state of the pipes and the pumping station there are cracks of metal, plastic, structural elements, the repair is reduced to disassembling the equipment, part of the water supply network and replacing damaged parts and pipes.However, the liquid during freezing does not immediately break the metal, and there are non-zero chances to save the equipment.

Important! Before defrosting, the station should be disconnected from the water supply network, if possible open the stop valves or unscrew the flanges of the problem area, creating a vanishing point for the expanding water.

The order of action with pipes depends on their type, as well as the available means and tools. Carts can defrost with boiling water, steel tubes warm up with a blowtorch. The process of temperature rise must be gradual, so as not to cause damage by a sudden change.

The most effective, but long way to defrost the mechanics of the pump - installation of incandescent bulbs. The object of heating must be placed in any limited space, for example, surrounded by a box turned upside down, whose walls are 200 or more millimeters away from the heat source. After that, the lamp turns on, its power must be at least 100 watts.

Pipes can be heated heating cableIt is not difficult to get it in any store selling electrical heating systems. By wrapping the frozen area and applying 220V to the cable, you can quickly and fireproofly defrost the system. Good results of applying this method are observed when working with pump mechanics.

Tips for trouble free operation

Pumping station for reliable operation requires proper installation. To guarantee long trouble-free operation, you need:

- install the pump on a flat, rigid platform or support that does not allow vibration;

- operate the station only at a positive temperature;

- not to allow overheating in the area of the pump (temperature above 40 degrees), for which it is rational to provide a system for blowing or ventilation;

- use only the diameter recommended in the documentation for the supply and removal of water so that the pump can show its declared characteristics;

- prevent pipe bending;

- to provide a drainage system for emergency drainage, as well as nozzles for filling the water in the supply circuit.

If water is drawn from a shallow well with a surface pump, care must be taken to ensure that the turbine impeller is always in the water. To do this, the end of the hose or pipe is immersed in water, making sure that the liquid contains as much of its length as possible. The best way to guarantee safety will be equipping the intake line with a float. His task is to raise and lower the end of the hose, constantly keeping it immersed in water.

The list of periodic system maintenance includes pressure control. The air in the pumping station is checked through a spool or nipple outlet on the body of the accumulator. Having attached to it the manometer, it is easy to see indicators. Nominal pressure - from 1.5 to 1.8 atm. With its deficiency, air is pumped through a vent with a compressor or bicycle pump.

/rating_off.png)