How does a home water pumping station work?

When organizing the water supply of an individual cottage or a small enterprise located in a rural area, it is required to properly equip the water intake point and lay the necessary pipelines. In the case of permanent residence and regular water consumption, the installation of an ordinary centrifugal pump cannot provide the user with an adequate level of convenience. For this purpose, special equipment has been developed and presented on the market, which is capable of comprehensively solving the problem of uninterrupted water supply for a private house or other separate object. This article is devoted to the device and the principle of operation of the pumping station, which can be easily found in a specialized store.

Content

Design features of a modern pumping station for domestic needs

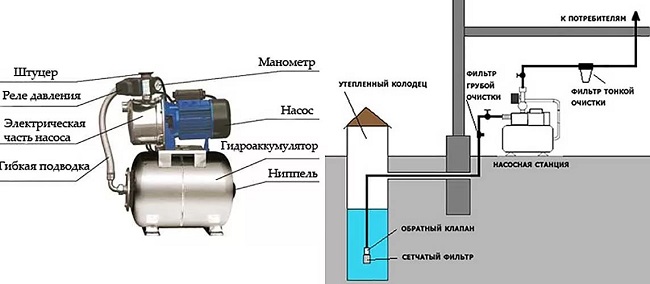

The water supply system of the building with the scheme of the pumping station, included in it as an integral part, includes several basic elements.

- Well or borehole, in which the primary accumulation and settling of the liquid. For year-round use it should be warmed.

- Suction pipeequipped with a check valve. Usually it is installed in the well or directly in front of the pump station coarse filter from mechanical impurities.

- Pumping station itselfproviding the object with water with the necessary flow and pressure.

- Pressure pipe with fine filterleading to all water dispensers.

The device pumping station for home plumbing is extremely simple and functional. It consists of the following mechanisms.

- Water centrifugal pump driven by an electric motor.When it is turned on, a vacuum is created in the suction inlet and an overpressure in the pressure port. As a result, the liquid is sucked from the well and is injected into the water supply manifold of the house.

- Manometer, allowing on-site to monitor how the pump works.

- Diaphragm accumulatorresponsible for the constant availability in the system of the necessary supply of water with working pressure.

- Pressure switch, giving control signals to start and stop the motor.

- Flexible hoseconnecting pump with hydroaccumulator.

- Valves for the possibility of shutting down pipelines at the time of audit, maintenance and repair of equipment.

Important! The device of the centrifugal pump does not allow to turn it on for a long time without filling it with liquid. This can lead to overheating of individual parts and failure of the entire unit. To exclude the creation of such situations, a dry running sensor is provided, which turns off the engine in the absence of water.

Sensor of the dry course DPR-6

How does such a system work?

For proper operation of the water supply system, you need to know the principle of the pumping station.Domestic water consumption happens periodicallytherefore there is no need for continuous operation of the pump. On the other hand, it is convenient for the tenant that the flow rate appears immediately after opening the tap. These tasks are solved in a simple and effective way.

A running pump provides the consumer with water and pumps it into the drive. At the same time in the entire system increases the overpressure until it reaches the set maximum value. At this point, the relay is activated and the motor turns off. In the process of fluid consumption, its pressure decreases until the control unit again issues a command to start the pump.

The design of the hydroaccumulator and its advantages over the water tank

The accumulator is a sealed container, designed to work under high pressure. Its internal space is divided into two parts. rubber membranefirmly attached edges to the walls of the apparatus. On one side of it water flows, on the other, air is pumped through the nipple to a pressure of 1.5 atmospheres.

The principle of operation of such a device is based on its periodic filling and release from liquid.Its pressure changes gradually due to the air cushion, working as a compressible and expandable springs. This design allows for a long time to expend water without turning on the pump.

Tip! Capacity is selected on the basis of the estimated fluid flow. For an average family, suitable devices for 25-40 liters. With large water consumption will require 100 or more liters. For summer cottage, used as a place of Sunday rest, 15 liters will be enough.

Pump stations with hydroaccumulator superseded outdated circuits that used as a drive pressure tanks. They had to be installed at high altitude, and they were emptied by gravity.. The modern version has a number of significant advantages:

- compact size;

- simple installation;

- the possibility of maintaining a large head;

- no risk of overflow in case of malfunction of the fill sensor.

When choosing equipment, it is better to choose models that can work without a tank.

Work control unit

The main advantage of the pumping station is work in automatic mode. In industrial installations, this may require a separate control cabinet with a variety of measurement and control devices.

The household equipment is completed with the regular control unit in which all necessary options are realized. Its main element is relay. It has two springs configured for maximum and minimum system pressure. They are connected to contacts that at the right time close and open the electrical circuit of the pump motor.

It is extremely useful function fluid flow controller, providing protection against dry running with the pump off when air enters the suction hose. On a number of models, electrical interlocks are implemented against motor overheating and power surges in the power supply network.

Distinctions of pump stations as the soaking-up devices

The most important characteristic of any surface pump is the depth of fluid intake. It depends on the type of equipment and accessories installed on the suction hose.

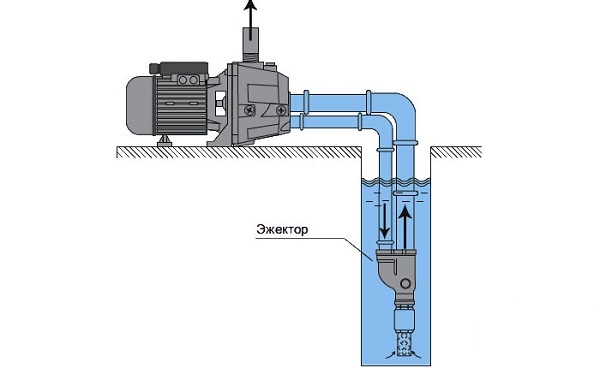

To improve pumping, an ejector is usually used - a small tube-shaped construction with an internal nozzle. It creates a vacuum due to a jet of water flying out of a narrow orifice at high speed.

No-pumping pumping stations even theoretically, they cannot reach a suction depth of 10 meters.In practice, this figure is always much lower. They are used when pumping from a shallow well. The presence of the ejector ensures a more stable operation of the surface pump with a large length of the receiving pipeline.

Pump stations with built-in ejector able to raise water from a depth of 7-8 meters. At the same time, air is first sucked away, and then water is pumped out. Such systems are installed in separate rooms, because they require good sound insulation.

Sometimes the ejector is placed directly in the well. For his work requires the connection of two pipes. In one of them, water is pumped under pressure from the pump to create a high-speed jet, and in the other, pumping occurs. Pumping stations with a remote ejector can take liquid from a depth of up to 50 meters. They do not emit strong noises, but their efficiency rarely exceeds 40%.

Proper operation of equipment

Pump stations are designed for long-term autonomous operation in continuous mode. They can be used for domestic water supply and fire fighting. Excellent performance and high reliability modern models of the brand Jumbo. They require minimal maintenance. In the process of their normal operation it is necessary:

- periodically conduct an external examination for the absence of gaps and extraneous sounds;

- at least once a year wash the coarse filter;

- in the case of a long break for the winter period, free all cavities from the water and store the dismantled equipment in a heated room;

- At the first start-up after re-preservation, check the correctness of all connections and make sure that the pump is running smoothly.

/rating_off.png)