Types of vacuum pumps and their principle of operation

In various spheres of human activity, a vacuum is required. This term describes the state of the gas phase, the pressure of which is below atmospheric. It is measured in millimeters of mercury or pascals. The dilution of gases occurs during the forced removal of substances from devices with limited volume. The technical device designed for this purpose is called a vacuum pump. It can be used independently or enter into more complex systems.

Content

Scope of vacuum pumps

Vacuum is widely used in various technical devices.It allows to reduce the boiling point for water or chemical liquids, to remove gases from materials that require increased homogeneity of the composition, to create sterile processing and storage conditions. With small dimensions and economical energy consumption, modern vacuum pumps make it possible to quickly achieve a deep degree of rarefaction. They are used in various processes and areas of activity:

- in the refining and chemical industries to maintain the necessary conditions for the reactions and the separation of the resulting mixtures;

- when degassing metals and other materials to create parts with a homogeneous structure and the absence of pores;

- in the pharmaceutical and textile industry for the rapid drying of products without increasing the temperature;

- in the food industry for packaging milk, juice, meat and fish products;

- in the process of vacuuming refrigeration and other equipment with increased requirements for the absence of moisture;

- for the normal functioning of automatic conveyor lines using vacuum suction pads as grippers;

- at the equipment of production and research laboratories;

- in medicine during the operation of breathing apparatus and dental offices;

- in printing for fixing thermofilms.

The principle of operation of vacuum pumps

Vacuum is created by mechanically removing a substance from an enclosed space. Technically, this is implemented in various ways. Principle of operation jet pump vacuum pump based on the entrainment of gas molecules by the flow of water or steam ejected at high speed from the ejector nozzle. Its scheme provides for the connection of the side branch pipe, in which a vacuum is created.

The advantage of this design is the absence of moving parts, and the disadvantage is the mixing of substances and low efficiency.

In the technique the most common mechanical units. The operation of a vacuum pump with a rotating or moving reciprocating main part consists in periodically creating an expanding space inside the case, filling it with gas from the receiving pipe and then pushing it out through the outlet. Constructive device of the vacuum pump at the same time can be very diverse.

Main types of vacuum pumps

In the manufacture of devices for creating vacuum, metal and plastic materials are used that are resistant to the chemical effects of the pumped medium and possess sufficient mechanical strength. Much attention is paid to the accuracy of the fitting of nodes and the tightness of the contact surfaces, eliminating the reverse gas leakage. Here is a list of the main types of vacuum pumps, differing in design and principle of operation.

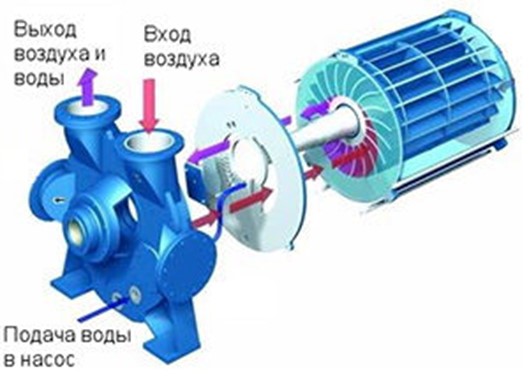

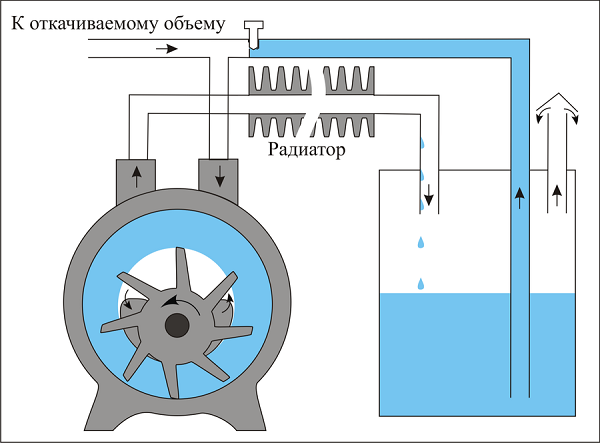

Water Ring

Water ring vacuum pump is one of the options for liquid ring units, using to create a vacuum pure water circulation. It has the form of a cylinder with a rotor with blades, rotating on a shaft that is offset from the center. Before starting, it is filled with liquid.

When starting the engine, the impeller accelerates water along the inner walls of the housing. A sickle-shaped vacuum region is formed between it and the rotor. It rushes gas from the pump inlet. Moving blades move it along the shaft and throw it through the outlet. Aggregates of this type are often also used. for partial gas cleaning due to its intense contact with water.

The use of fluid as a working body provides many advantages.

- Water rotating in the space between the rotor and the pump casing eliminates the likelihood of gas re-breakthrough, replacing seals and reducing the requirements for precision parts.

- All rotating parts of the pump are constantly washed by liquid, which reduces friction and improves heat removal.

- Such devices rarely require repair, have a long service life and consume a minimum of electricity.

- Working with gases containing water droplets and small mechanical impurities does not adversely affect the technical condition of the equipment.

The latter circumstance is important when using such pumps for pumping air from tanks containing moisture. They are used for air conditioners and other refrigeration units when evacuating the system before filling them with freon.

Rotary vane

Such pumps have a cylindrical body with a carefully polished inner surface and a rotor located inside it. Their axes do not coincide, therefore the lateral clearance has a different size. The rotor includes special moving plates, which are pressed by the springs to the body and divide the free space into sectors of variable volume. When the engine is turned on, the gases start moving in such a way that a negative pressure is always created in the suction inlet and an overpressure in the pressure head.

To reduce friction plates are made of anti-friction materials or apply special low viscosity oils. Pumps of this type are capable of creating a sufficiently strong vacuum, but they are sensitive to the purity of the pumped liquid or gas, require regular cleaning and contaminate the product with traces of lubricant.

Diaphragm piston

The working body of the pumps of this principle of action is flexible membraneassociated with a lever mechanism. It is made of modern composite materials that are resistant to mechanical loads. Its edges are firmly fixed in the case, and the central part under the action of an electric or pneumatic actuator bends, alternately reducing and increasing the space of the inner chamber.

The change in volume is accompanied by the absorption and ejection of incoming gases or liquids.When working together in antiphase of two membranes, continuous transfer mode is provided. The valve system controls the proper distribution and direction of the flow. The mechanism has no rotating or rubbing parts in contact with the pumped product.

TO the advantages of such pumps should include:

- no contamination of the product with grease or mechanical impurities;

- full tightness, eliminating leakage;

- high profitability;

- ease of flow control;

- long-term operation in dry mode, which does not harm the structure;

- the ability to use a pneumatic actuator to work in an explosive environment.

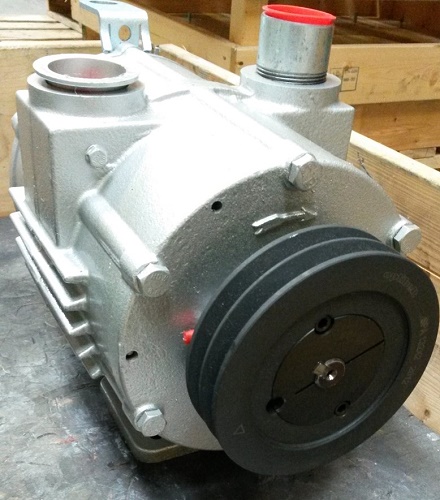

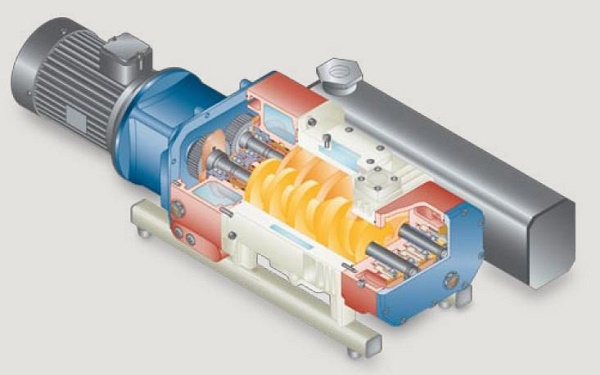

Screw

The principle of operation of screw pumps is based on displacing a fluid or gas along a rotating screw. They consist of a drive, one or two rotors with a helical configuration and a stator of the appropriate shape. High precision manufacturing of parts does not allow the pumped medium to slip back. As a result, an overpressure is generated at the pump outlet and a vacuum at the intake.

Such equipment due to the high quality requirements of manufacturing is not cheap.It can not be kept for a long time on the "dry" mode.

The main advantages of such pumps:

- flow uniformity;

- low noise level;

- the ability to pump fluid with mechanical inclusions.

Whirling

Swirl vacuum pumps with their design resemble centrifugal equipment. They also have an impeller with blades rotating on a central shaft. The principal difference lies in the location of the receiving pipe on the outer circumference of the housing, and not in the region of the central axis.

The minimum clearance between the impeller and the casing ensures a steady movement of the pumped liquid in the desired direction. Units of this type are capable of creating a sufficiently high discharge pressure and have a self-priming effect. These pumps are easy to use, easy to repair and have proven themselves when pumping gas-liquid mixtures, but they have low efficiency. They are sensitive to the ingress of mechanical impurities that can lead to rapid wear of the impeller.

Independent manufacture of a vacuum pump

If you are not ready to bear the cost of purchasing factory equipment, try to make a vacuum pump with your own hands.For pumping air from a small volume tank can be useful medical syringe or a slightly upgraded hand bike pump.

Consider the manufacture of a vacuum unit. from the compressor of the old refrigerator. It is already designed for pumping gas and with minimal repairs can create a vacuum. Your actions will be extremely simple:

- at some distance from the compressor, cut with a hacksaw on metal two copper tubes suitable for it;

- dismantle the compressor together with the power supply circuit or replace it with the starting relay with a new one by analogy with the old one;

- on the copper pipe that went from the condenser, put on a duritovy hose of a suitable diameter and connect it with the other end to a vacuumized container;

- for tightness, you can use a regular clip or use a twist of steel wire;

- connect the vacuum pump to the electrical network and after starting up the air from the second copper pipe to ensure that it works properly.

Important! The compressor of the refrigerator is not intended for operation in a humid environment, therefore it is necessary to ensure that no water gets on it.

/rating_off.png)