Overview of the main types of pumps and their applications

Pump is hydraulic devicewhich provides absorption of water, its injection and movement. In their work, they use the principle of transfer of liquid kinetic and potential energy. Pumps are of several types, and the division is based on their technical parameters. The main differences between different types of water pumps are the different efficiency, power, capacity, head and pressure of the effluent.

Content

General classification

Currently, there are more than three thousand types of pumps. They differ in structure and purpose,as well as suitable for different areas of use. All this diversity can be divided into two large groups: dynamic and positive displacement pumps.

Displacement pumps - These are devices in which a substance moves due to a constant change in the volume of a chamber, while it alternately aligns with the inlet and outlet. They, in turn, can be divided into:

- membrane;

- rotary;

- piston

Dynamic - these are models in which water moves with the chamber due to hydrodynamic forces, and there is a constant communication with the inlet and outlet of the pump. Dynamic pumps are jet and blade, with the latter in turn are divided into centrifugal, axial and vortex.

Below all these types of pumps, as well as their classification will be discussed in more detail.

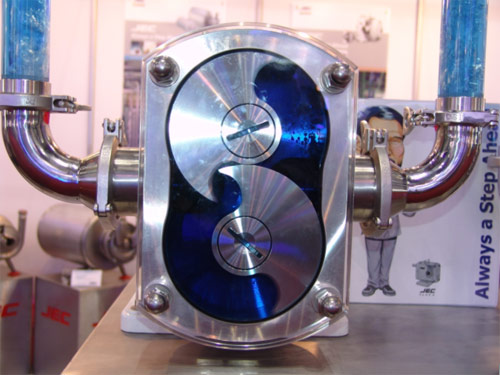

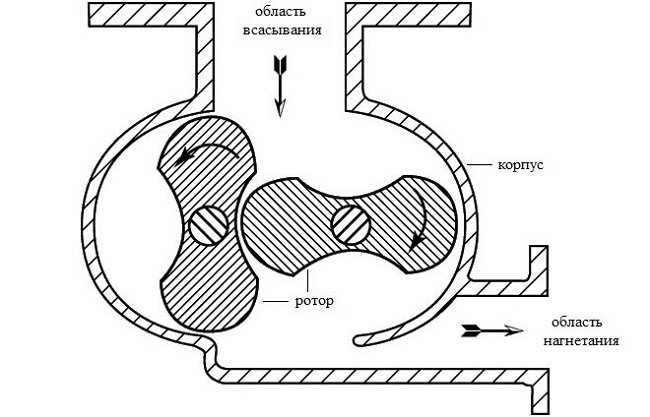

Rotary devices

Overview of water pumps open rotary devices. Their fundamental difference is no valve. In other words, a rotary water pump moves water by pushing it out. This process is carried out by a special work item - the rotor. This is implemented as follows: water enters the working chamber.The movement of the rotor along the inner walls of the working chamber forms a change in the volume of the enclosed space, and the water is ejected according to the laws of physics.

Advantages of rotary pumps:

- high efficiency;

- self-priming water;

- the possibility of reverse water supply;

- pumping substances of any viscosity and temperature;

- low noise level;

- no vibration.

Of the minuses it is worth noting that the purity of the pumped liquids must be ensured (without solid inclusions). In addition, complex construction requires expensive repairs.

Due to the possibility of working with aggressive and viscous substances, rotary pumps are used in the chemical, oil, food, marine industries. Subspecies of rotary pumps - screw - are actively used in oil production. Another field of application is public utilities, where they are used to maintain pressure in the heating system, and the pump does not need lubrication and cooling.

Piston models

The device of the piston pump is based on the displacement of water mechanically. This is one of the oldest types of water pumps, but in its modern form, its device is much more complicated than before.In particular, these pumps have an ergonomic and durable housing, a developed base of its constituent elements, as well as flexible connectivity to the water supply. In this regard, they are widely distributed, both in industry and in everyday life.

The pump is a metal hollow cylinder, which, in fact, is the body - it moves the fluid. The physical impact on her carries plunger piston typewhose work may resemble a hydraulic press. The operation of this device is based on reciprocating movements. When moving up (translational motion) in the chamber creates a vacuum of air, which ensures the absorption of water. Water enters the chamber through the inlet with a valve, which at this moment opens the hole. When the return movement of this valve returns to its place, and the valve opens the outlet. At the same time the piston squeezes out water. Almost the same principle works the most ordinary syringe.

In this work, there is one drawback - the liquid flows unevenly. To eliminate this phenomenon, several pistons are used at once.which move with a certain periodicity, which ensures a smooth flow.

Exist double acting piston pumps. Here, the valves are located on both sides, and the water several times passes through the entire cylinder, that is, the piston disperses the water inside the working space during movement and pushes some of it out of the pump. Due to this, it was possible to reduce the pulsation in the pipeline. The dual-type construction has a minus - a more complex system, which makes it less reliable.

The main advantage of piston pumps is simplicity and durability, the main drawback is low productivity.. In general, this type of pump can be made more efficient, but this does not make sense, since more power at lower cost can provide other types of pumps for pumping water.

The scope of such pumping equipment is quite wide. They allow you to work not only with water, but also with an aggressive chemical environment, as well as explosive mixtures. Due to the fact that such devices cannot pump large volumes of liquid, they are not used for large tasks.However, these pumps are often found in the chemical industry. They can also be used to provide an autonomous water supply system for home or for watering. Another place where such devices have successfully recommended themselves is the food industry. This is explained by the fact that piston models are delicately related to substances passing through them.

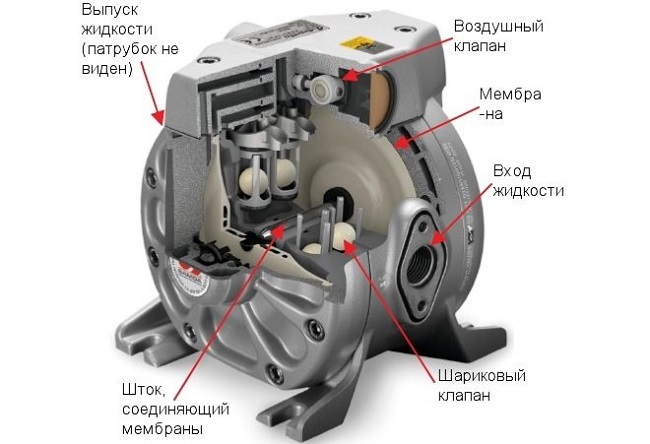

Membrane devices

Diaphragm pump is a relatively new type of equipment for pumping liquids and other substances. This type of equipment is capable of work with gaseous medium and makes it through a special membrane or diaphragm. It performs reciprocating movements and with a given cyclicality changes the volume of the working chamber.

The design of the device includes:

- a membrane;

- working chamber;

- stem for connecting the diaphragm to the drive shaft;

- crank mechanism;

- valves to protect against the receipt of a substance back;

- inlet and outlet.

Such pumps can have one or two working chambers. Devices with one camera are more common, with two used in those places where higher performance is required.

The work is carried out as follows: when launched, the stem bends the membrane, which increases the volume of the chamber and creates a vacuum effect in it. This phenomenon ensures the absorption of the pumped medium. After the chamber is filled, the stem returns the diaphragm into place, the volume decreases sharply, and the substance is pushed out through the outlet. At the same time, in order to prevent the liquid or gas from returning back at the time of the return movement, the input is automatically blocked by a special valve.

Exist models with two valveslocated parallel to each other. Here, the process is carried out in a similar way, only two working chambers, and with each movement water comes out of one and enters the other. Such devices are considered more efficient.

Advantages of diaphragm pumps:

- can work with any environment;

- small size;

- quiet work;

- lack of vibration;

- simplicity and reliability of the design;

- energy efficiency;

- maintaining high purity of the pumped substance;

- low price;

- long service life;

- do not require special or frequent care, they do not need lubrication;

- replace the damaged parts can a person without special education;

- possess high universality.

With such an abundance of pluses, there are no significant minuses.

Diaphragm pump is widely used in medicine and pharmaceuticals, in farms (in milking machines). They are used for food production in the nuclear industry. With their help, make metering pumps for use in the production of varnishes and paints, they are used in printing and in various places where there is a need to work with toxic and hazardous substances. It’s safe to work with the latter since diaphragm pumps have high tightness.

Jet pumps

Inkjet models are the simplest of all possible devices. They were created in the 19th century, then they were used to pump water or air from medical tubes, and later they were used in mines. Currently, the scope of application is even wider.

The design of the jet pump is very simple, thanks to which they practically do not require any maintenance.. It consists of four parts: a suction chamber, a nozzle, a diffuser and a mixing tank. All the work of the device is based on the transfer of kinetic energy, while here mechanical force is not used. The jet pump has a vacuum chamber into which water is sucked. Then it moves along a special pipe, at the end of which there is a nozzle. By reducing the diameter of the flow rate increases, it enters the diffuser, and from it into the mixing chamber. Here, water is mixed with the functional fluid, due to which the speed is reduced, but the pressure remains.

Jet pumps are of several types: an ejector, an injector, an elevator.

- Ejector only pumps the substance. Works with water.

- Principle of operation injection pump - injection of a substance. Used for pumping out steam.

- Elevator used to reduce the temperature of the carrier, which is achieved by mixing with the functional fluid.

Thus, jet pumps are used to work with water, steam or gas. They can also be used to mix different substances or to raise liquids (airlift function).

This type of pump is common in various industries. They can be used alone or in combination with others. Simplicity of a design allows to use them in emergency situations with shutdown of water, and also for fire extinguishing. They are also popular in air conditioning and sewage systems.Many models of jet type are sold with different nozzles.

Pros:

- reliability;

- no need for constant maintenance;

- simple construction;

- wide scope of application.

Minus - low efficiency (no more than 30%).

Centrifugal pumps

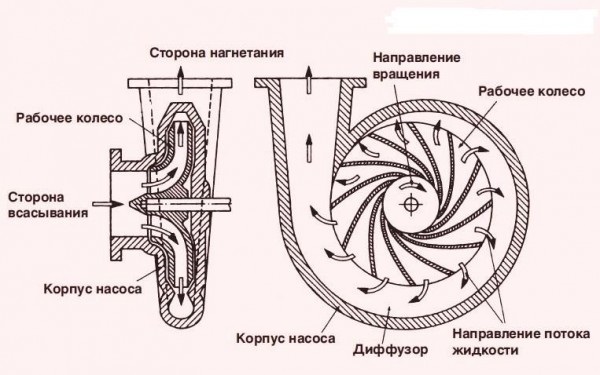

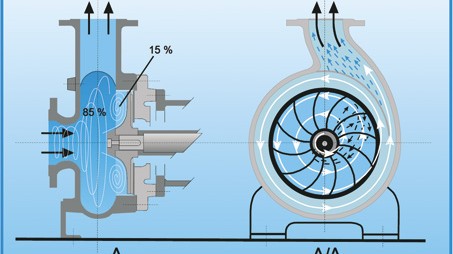

In this type of device, the main working element is disc on which the paddles are fixed. They have an inclination in the direction opposite to the direction of movement. The blade is fixed on the shaft, which is driven by an electric motor. The design can be used one or two wheels. In the second case, the blades connect them together.

The principle of operation of a centrifugal pump is based on the fact that water through the inlet pipe enters the working chamber. The medium captured by the rotating blades begins to move along with them. Centrifugal force moves water from the center of the wheel to the walls of the chamber, where it creates increased pressure. Due to it, water is discharged through the outlet. Due to the fact that water moves constantly, pumps of this type do not create a pulsation in the water supply.

The use of centrifugal pumps for domestic purposes allows you to perform various tasks.Often they are used to extract water from a well or well. The water pumped out in this way can be used for arranging the water supply at home, as well as used for watering the site. With the help of centrifugal models you can provide circulation of warm water in the heating system: due to the fact that the pumping centrifugal pump does not pulsate, there will be no air in the system. Various subspecies of such pumps can be used to pump water from basements or pools, to remove fecal matter, and also as drainage machines.

It should be noted that simple pumps with a centrifugal system are designed for clean water without solid elements. Various subspecies allow you to work with polluted environments.

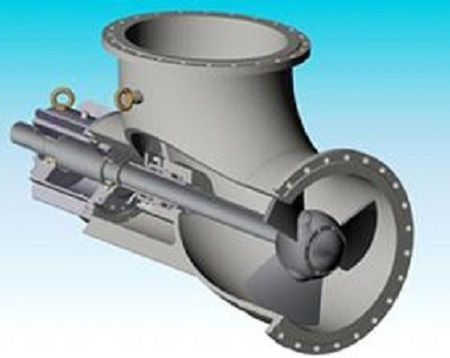

Axial models

In devices of this type completely no centrifugal force, and the whole process takes place by transferring kinetic energy. In the working chamber, which has a bend, the blades are on the axis. It is located in the direction of flow. Water moves through the chamber, the axis increases its speed of movement and pressure. Due to this design, the requirements for their production are quite serious.Most often, such pumps are used as ballast and control systems in ships, floating docks and similar equipment.

The main task of these pumps - pumping fresh and salt water. Used for drainage, supply and purification of water. Axial pumps can have very compact sizes and be installed in a water supply system.

Swirl Pumps

Vortex pumps have a similar structure to centrifugal ones, only in them the water supply is carried out in such a way that when it enters the chamber it moves tangentially relative to the periphery and shifts to the center of the wheel, from which it again goes to the periphery due to the movement of the blades, and from there discharged through the outlet. The main difference is that with one revolution of the wheel with blades (impellers) the cycle of suction and ejection of water occurs many times.

This design allows you to increase the pressure by 7 times, even with a small amount of water - this is the fundamental difference between the vortex and centrifugal pumps. As well as centrifugal pumps, these models do not tolerate the content of solid inclusions in water, and also cannot work with viscous liquids.However, they can be used to pump gasoline, various liquids containing gas or air, and aggressive substances. Minus - low efficiency.

Such pumps are used for different purposes and areas, but their installation is advisable if the amount of the substance you need to work with is small, but you need high pressure at the outlet. Compared to centrifugal models, these devices are quieter, smaller and cheaper.

Classification by type of food

All water pumps have a specific method of power - from electricity or at the expense of liquid fuel. In the latter case, they are necessarily equipped internal combustion engine. As a liquid fuel, a mixture of gasoline and oil or diesel fuel is used.

Petrol models are cheaper and run more quietly. Diesel devices are charged with diesel fuel. The price is more expensive, but the fuel is cheaper. In addition, they are more noisy.

Liquid fuel pumps are otherwise referred to as a motor pump. Their main advantage is ease of use and mobility, that is, you can use anywhere, if there is no electricity.

Electric models used to operate alternating current.The owner of such a pump does not need to worry about the availability of fuel, but care should be taken to ensure that electricity is always available, which is not always convenient.

Fluid quality classification

Different types of pumps impose certain requirements on the purity of water. All devices can be divided into three types.

- For clean water. The content of solid particles in it should not exceed 150 grams per cubic meter. Such models include surface pumps, as well as well and well pumps.

- For moderately polluted water. Insoluble impregnations from 150 to 200 grams per cubic meter. Drainage, circulation and self-priming types. Also some fountain models.

- For dirty water. Solids from 200 grams per meter cubed. Drainage and surface sewer models.

Location classification

All pumps are also divided into submersible and external (more common name - surface). The first type is directly in the water or partially in it. Models that are not fully submerged are referred to as semi-submersible.

It is worth noting that there are several types of submersible pumps.

- Vibrating - here the work is based on the electromagnetic field and the vibration of a special mechanism; such types of pumps require certain installation rules. In particular, there are strictly specified distances to the bottom.

- Centrifugal machineswhich were discussed above.

All submersible pumps may have an engine that is already built into the housing, that is, it is under water. In some models, it is located on the surface.

Outdoor pump located directly next to the reservoir. In this case, the suction mechanism performs its work through a special hose. The further the pump is located from the water, the more powerful it should be.

Most often, surface pumps are used in country houses and country sites. They have high efficiency and small size, which makes them popular for use in everyday life. Can be equipped with automaticsthat makes them completely autonomous.

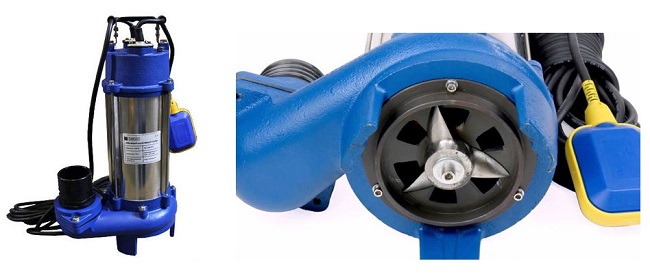

Submersible pumps

Submersible pumps, among other things, are divided by purpose:

- borehole;

- well;

- drainage;

- fecal

Downhole have an elongated shape and are used to extract water from wells. Compact dimensions allow to lower into small wells with a small diameter, however, production can be carried out from a very great depth. Differ in the high power of work. They are used only for water with low pollution or completely clean.

Well wells used for pumping water from mines and wells. The main difference from the borehole - a larger size and a smaller depth of immersion. They are powerful enough, they can work with water containing silt, sand or clay. Quite quiet and does not vibrate.

Main task drainage is pumping contaminated water from basements, trenches, pits and other places. There are varieties with knives for grinding, as well as for working with slightly polluted media.

Fecal pump It has no significant differences from drainage, except that they are designed for heavily contaminated water with large solids (about 35 mm in diameter). Also, they are equipped with knives for grinding garbage. Such pumps can be both submersible and external.

Surface pumps

The main difference between surface pumps is their location near the water. They can be divided into several types:

- self-priming;

- automatic;

- pumping stations.

Self-priming pumps there are no ejector and ejector. In the first case, the water is drawn in by the structure itself, in the second by creating a vacuum in the chamber. They are used for irrigation, delivery of drinking water or for domestic needs, as well as for the intake of water from water bodies on the surface (river, pond). Water should be clean or with little pollution.

Automatic pumps Provided with automatics that simplifies the process of use. The pump does not need to follow. Automatic pumps are powered by electricity. The machine itself can be installed directly in the model or as a separate system. The main task is to optimize the use, as well as the protective function. For example, the device will stop working with a sharp shallowing of a reservoir, an increase in the temperature of the pumped substance, or when the voltage drops in the network.

Pumping station consists of the pump itself, check valve, control system and battery.Such a device has a rubber bulb mounted inside the metal body. Water is pumped into the pear and air around it. A special sensor responds to changes in ambient pressure that occur as the pear is filled with water. When the pressure reaches its maximum, the sensor stops the flow of water.

Ease of use of such units in simplicity and functionality, the ability to use when power outages. They can also be provided with water at once several points.

/rating_off.png)