Features of the use of vortex pumps

Pumps are used for a variety of tasks: in the domestic sphere for organizing watering or water supply at the site, in industry for pumping water from wells, for pumping gaseous and volatile substances, in utilities as pumps in small boilers. All pumping equipment can be divided into several types, which differ in the device, purpose and characteristics. Below we will consider the features of vortex pumps, which are quite widespread.

Content

Where is used vortex pump

The vortex pump mainly performs the task of pumping water, but can also be used to transport gaseous substances.There are several subspecies of devices, but all will have the same element as an impeller with special blades. The principal difference between the vortex pumps is the ability to work with a small amount of water, while they are able to provide a sufficiently strong pressure.

Accordingly, the main scope of application is the places where it is necessary to ensure a large water pressure with insignificant volumes. The water pump of vortex type is used for domestic or industrial purposes. They are used in automatic water supply systems for irrigation, they are suitable for supplying liquids of one type or another, and can act as a compressor to increase the pressure in the water supply system. In particular, the purpose of such a pump is as follows:

- water supply of country houses with the help of an automated pumping station;

- pumping gasoline and kerosene at gas stations;

- power supply of low-power boiler installations, etc.

Often pumps of this type are used in the chemical industry for pumping chemically aggressive substances. Due to the simplicity of construction, chemically resistant alloys are used as materials for the manufacture of vortex pumps.hard to figure cast.

Device and principle of operation

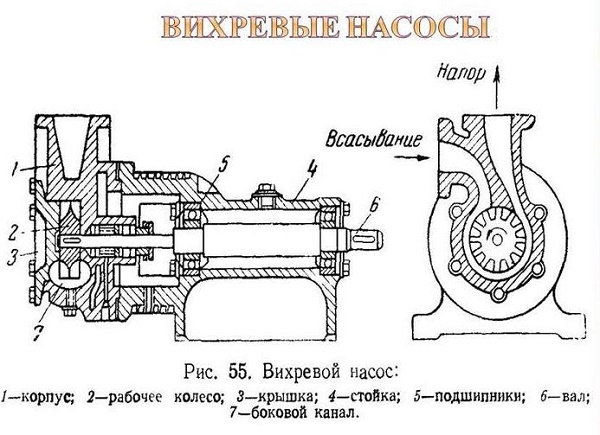

As mentioned above, the main work item of this type of device is wheel (impeller) with bladesthat act as blades. The blades towards the axis of the wheel are radially or obliquely. By itself, the impeller is a steel disc, along its outer circumference there are carved pits that form the blades.

The wheel with blades rotates inside the cylindrical body, and the distance from the end of the blade to the wall is minimal. The principle of operation of the vortex pump is that water is sucked into the inlet and twists into the vortex due to the impeller. At low power consumption, the flow rate increases significantly, and the liquid with great pressure is ejected from the outlet.

It is worth noting that the inlet and outlet connections are located at the top of the pump. This design provides self-absorption of liquid at the start of equipment operation.

There is a special pump in the vortex pump. drain channelwhich connects the outlet with the inlet, while between them they are separated by a special partition.It covers at least two blades, and the distance between it and the wheel is not more than 0.2 mm. Thus, the movement of the pumped water and impeller creates centrifugal force, which increases the pressure. Due to this design, it was possible to achieve not only an increase in pressure at the outlet, but also to provide an opportunity to pump gas-liquid substances.

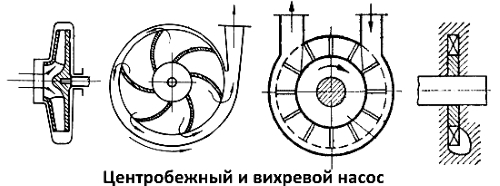

Due to the design features with the same impeller size and equal frequency of the rotations, the operation of the vortex pump is approximately 7 times more efficient than the centrifugal pump.

Advantages and disadvantages of vortex pumps

Vortex pumps have their pros and cons. The advantages include a large pressure at the outlet, the function of self-suction of water, the ability to pump not only liquid, but also volatile substances, as well as structures with gas. With the help of such devices it is possible to carry out not only pumping, but also the transportation of water through pipes. Submersible pumps with a vortex system can be used at a depth of up to 20 meters.

The main disadvantage is low efficiency. It is about 45%; if it is necessary to ensure high production capacity, it is better to choose a centrifugal pump, since it will be more profitable economically.At large enterprises, the models in question are used only because of the impossibility of using centrifugal ones. Another serious drawback - the vortex pump can not pump water, which is interspersed with solid particles. Also such devices not suitable for viscous substances.

Classification

Vortex devices may differ in several ways. Currently, there are the following types of vortex pumps:

- open and closed - vortex;

- submersible and surface;

- combined.

Each of them has a different purpose and structure.

Open-vortex and closed-vortex

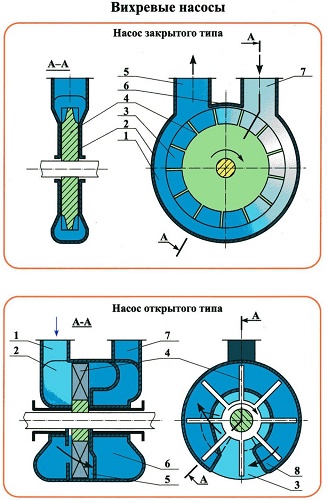

An open-vortex pump differs from a closed-vortex pump in that it has longer blades, the impeller is smaller in diameter than the outlet channel, and the annular channel itself is connected only to the discharge port. In closed models, the blades are shorter and located at different angles, the diameter of the wheel coincides with the diameter of the inner chamber, and the channel connects the inlet and outlet.

The difference in the following. Water enters through the inlet and enters the working chamber, where, in the form of a vortex, it is sent to the connecting channel and through it exits through the outlet pipe under pressure.For closed devices, due to the same diameter of the working chamber and the wheel, water immediately flows into the connecting channel, a vortex is formed there and the pressure increases.

Submersible and surface models

The difference between these models is clear from the name: the submersible ones are located directly in the pumped medium, the surface ones are located next to it. The first option is most often used simply for pumping liquids or not too viscous substances, the second is used for circulating water, for example, in irrigation systems or for water supply at home.

Combined options

Free-vortex models allow you to work with highly contaminated substances. They are used as fecal or drainage pumps, used in sewage treatment plants and in the mining industry for pumping water from wells during drilling.

Centrifugal vortex pumps have higher efficiency in comparison with the classical vortex models, they are able to work with liquids with a heating temperature of not more than 105 degrees. The difference lies in the fact that both a centrifugal and a vortex wheel are installed at the same time.

Vortex type vacuum pumps - this is a kind of blower.With their help, you can ensure the distribution of hot or cold air, as well as to achieve a small vacuum. Often used for drying glass containers and aeration of reservoirs.

Which pump is better - vortex or centrifugal?

To answer the question, which is better, a vortex or centrifugal pump, you should carefully look at characteristics of vortex pumps:

- small size and lower price in comparison with centrifugal;

- ability to create high pressure;

- work with pure substances;

- quite high noise level.

Currently, vortex pumps provide performance from 8 to 60 cubic meters per hour, and the pressure varies from 25 to 250 meters.

Based on the characteristics of the vortex models, we can conclude that they are more suitable in the industry, as they are able to pump not only liquids. Due to the high noise they are not suitable for working in residential premises or located in close proximity to the house. Due to the price and compact size, it is advisable to use them at small pumping stations, because they can work with a small flow, but with a great pressure.They are suitable for farms as a water supply system for irrigation. Such pumps are well suited for auxiliary boiler stations, as well as a compressor for the circulation of water. Another advantage is the simplicity of design and repair.

/rating_off.png)