Calculation of the main parameters of the pump for home use

A water pump is a device that has been used for pumping fluids for a long time. Without this equipment can not do neither at the dacha, nor on the plots. Water pumps are used to supply water from wells and wells to the irrigation and irrigation systems, to fill tanks with water, to ensure uninterrupted operation of the water supply system, and to pump out water when drying sections.

Content

Types of pumps used in everyday life

General information about the pumps say that they are units, the main purpose of which is pumping liquids using pressure created artificially. That is, the pump is hydraulic mechanismthat converts the mechanical energy of the drive into the energy of water, ensuring its movement.

There are a large number of types of devices of this type, each of which is designed to perform specific tasks in certain conditions. The units differ not only in the device, but also in the method of transporting water. For domestic purposes in a private house centrifugal, vortex and vibration pumps are used. Also, these types of units can be either immersed or working outside the liquid, that is, surface.

Centrifugal machines

Centrifugal type hydraulic machines are the most popular and popular units for domestic use.. Such popularity is not accidental. Centrifugal machines have a very simple design and are easy to repair at home. Besides all this, it is very reliable pumps, distinguished by their durability during operation.

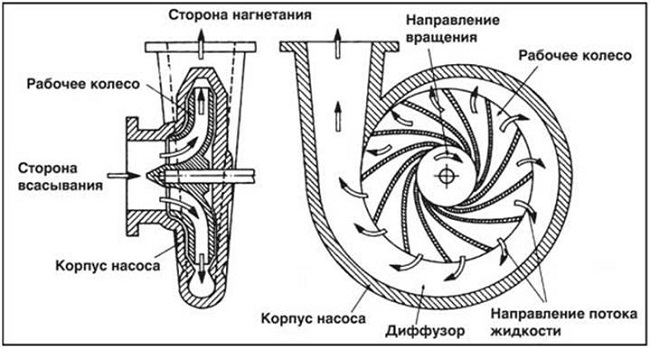

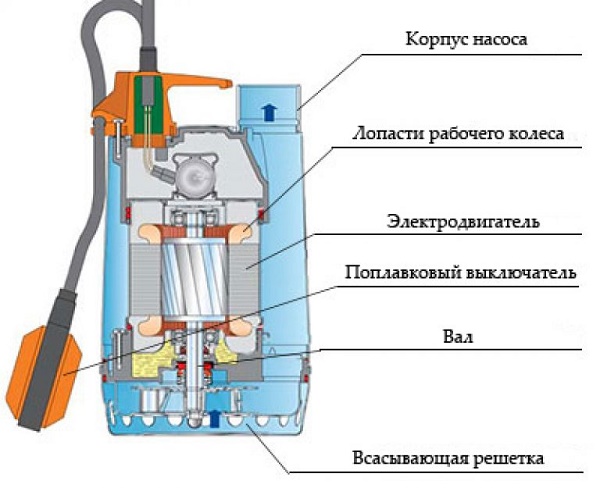

A centrifugal pump consists of only 2 main elements: the body (snail) and the impeller with blades.

The principle of the centrifugal apparatus simple:

- the water entering the chamber, where the rotating impeller is located, is captured by its blades;

- a centrifugal force is created in the chamber, which presses the water against the walls of the housing;

- as a result, due to the appearance of excessive pressure in the diffuser, water is pushed out through the outlet;

- At the same time, when water leaves the diffuser, a vacuum is created in the center of the chamber, which promotes the absorption of fluid through the inlet.

Centrifugal units are water pumps for domestic use. Therefore, they can be used for the following tasks.

- To supply water to the system watering and irrigation of plants. In this case, with the help of hydraulic machines, liquid is pumped out of wells and boreholes, from surface reservoirs, as well as from natural or artificial reservoirs.

- The devices allow you to supply water to autonomous water supply systems.

- Units allow you to remove the accumulated water in the cellars, basements and accumulated water on the territory of the infield.

Vortex hydraulic machines

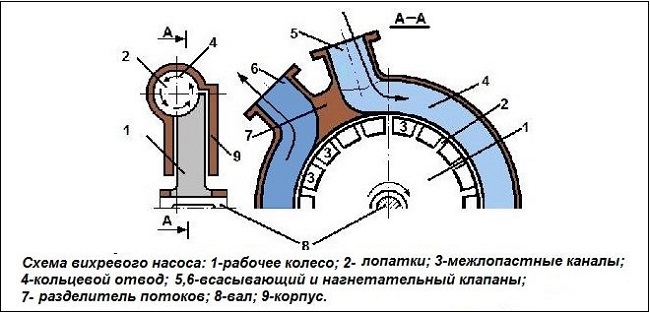

The main element of the vortex apparatus, as well as centrifugal, is Working wheel. But its structure is somewhat different from the impeller of the centrifugal unit.

The impeller is a disk with blades located around its circumference. The disk is installed in the case with the inlet and outlet pipes placed in its upper part. The figure below shows the structure of the pump vortex type.

The impeller is set eccentrically in relation to the annular outlet. The fluid is fed into the chamber tangentially to the impeller and moves around the ring due to centrifugal forces. Both channels, inlet and exhaust, are separated by a partition. When the impeller rotates, an underpressure is created near the inlet nozzle, which facilitates the absorption of liquid. Overpressure is created at the outlet, which pushes water out of the apparatus.

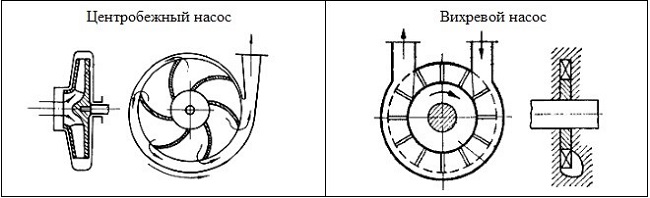

The following figure shows difference in design between centrifugal and vortex pump.

Due to the fact that vortex devices are capable of creating a high pressure of a liquid (3–9 times more than a centrifugal device) with a small flow, they are most often used for water supply, installing at pumping stations. After all, in order to supply water to an apartment located on the 9th floor or higher, a sufficiently large pressure in the system is required, and only vortex pumps can cope with this task.

Also, a vortex pump is a universal unit capable of pumping liquid-gas mixtures and volatile liquids, such as kerosene, gasoline, and others. Therefore, this device is used in refueling systems.

Vibrating

Vibration type devices are very popular among summer residents due to low power consumption and low cost (from 800 to 1500 rubles).

But when choosing a pump for pumping water should be borne in mind that vibration is detrimental to any mechanism. Vibration apparatus, whose service life rarely exceeds 2 years, is no exception.

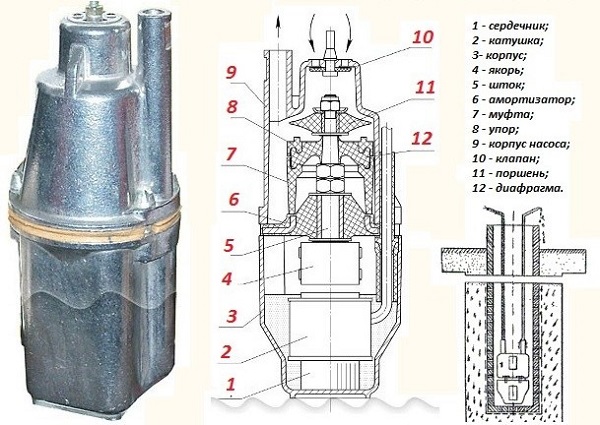

The following figure shows the internal structure of the vibrating apparatus for pumping water.

As can be seen from the figure, the pump is designed in such a way that in it no rotating parts. An electric coil (2) is used as a motor in the apparatus (see figure above), which creates a magnetic field. This field attracts the anchor (4) mounted on the rod (5).Also mounted on the piston rod (11). When it goes down together with the rod, a vacuum is created in the upper chamber of the apparatus, as a result of which the valve (10) opens, and water begins to flow into the chamber. After the disappearance of the magnetic field, the rod rises along with the piston. In this case, the inlet valve closes and the outlet valve opens, and the water flows out under pressure.

Due to the alternating current feeding the coil, the appearance of a magnetic field occurs in pulses with a frequency of 50 Hz. That is, the piston moves up and down with a frequency of 100 times per second.

The vibrating water pump can be used for the following purposes:

- pumping water from a newly dug well to clean it;

- water supply from a well for consumer needs;

- water supply from various tanks (tanks, cisterns, etc.);

- pumping water from rooms exposed to flooding;

- pumping water from trenches and trenches;

- water supply for irrigation from open water sources such as river, lake, pool.

It is not recommended to use a vibrating pump to supply water from a well.. This fact is explained by the detrimental effect of vibration on the walls of the well, as a result of which they fall off.The collapse of the borehole wall will completely remove it from the troja. In addition, the device itself will be covered with earth at a great depth, from where its extraction will be impossible.

Surface and immersion devices

In the market of pumping equipment there are 2 types of units for pumping liquid: submersible and surface. The second is called pumping stations. Work surface apparatuses on the principle of suction. Pumping stations may include either centrifugal or vortex pumps. The performance of these devices depends on the height at which you want to raise the liquid. In practice, household units are able to lift water from a depth of not more than 8 m.

Units whose working part is in a liquid are called submersible. These devices can be both vibration type and centrifugal, the construction of which was mentioned above. The main advantage of submersibles over surface ones is that they are capable of delivering water from a depth of more than 8 meters. This feature is especially useful during the dry season, when the groundwater level drops significantly.

Characteristics for pump selection

If you decide to conduct water supply in your summer cottage or in private housing construction, for which a well or a well is a water intake, the pump must be selected after carrying out accurate calculations. The latter should include the length of the pipeline, the immersion depth of the hydraulic machine, the distance to the static water mark in the well and other parameters. Also, when choosing equipment for water supply, it is necessary to properly study the main characteristics of the pump, such as power consumption, performance, pressure and noise characteristics of the unit.

Power consumption

Pump power is a performance characteristic that should be considered when installing a unit.The more powerful the unit, the a larger cross section needs a wire to connect it. In addition, if the house has weak wiring, then it is necessary to pull a separate power supply line to the device, and install the protection system in it in the form of a circuit breaker.

Performance

The volume of fluid that is pumped over a certain period of time determines the flow rate of the pump, that is, its performance. Performance parameters are usually denoted in l / min or m3/ h

It should be assumed that the deeper the device is immersed in the well, the less will be its performance. Therefore, these parameters should be taken into account when calculating

Head pressure

In order to choose the right pump, it is necessary to calculate the pressure value, which is defined as the energy transferred to the fluid from the moving elements of the unit, for example, a piston or impeller. In simple words, the pump head is height to which the unit can raise water. Measured pressure in meters.

Noise level

Since the unit is powered by an electric motor, the appearance of noise during its operation is inevitable. The noise is mainly caused by the rotation of the motor bearings and the impeller mounted on its shaft for cooling. In each unit manual indicates the level of noise that it produces. Therefore, the selection of the pump must be done not only on the above indicators, but also on the level of noise.

If the pump you choose is quite noisy, then it must be installed in the basement or in a separate building from the house.

If you are going buy submersible unit, there is no need to worry about the noise that it will emit, since it will work deep underground, which is a good sound insulator.

Calculation of parameters of the submersible pump

Before choosing a submersible pump, it is recommended to calculate such parameters as performance and pressure.

Performance calculation

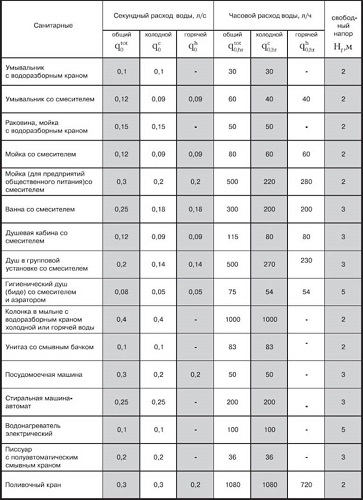

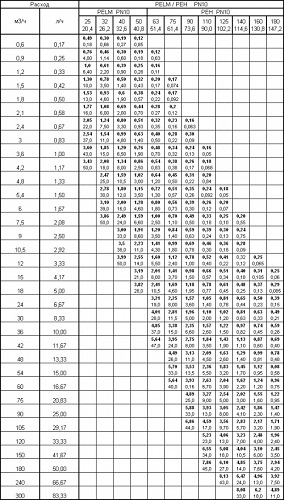

In order for the equipment to fully meet the needs of residents of the house in the water, it is necessary to correctly calculate the performance of the pump before buying it. The total water flow can be found if summarize its costs at all points of consumption in the House. To simplify the calculations, you can use the flow rates shown below.

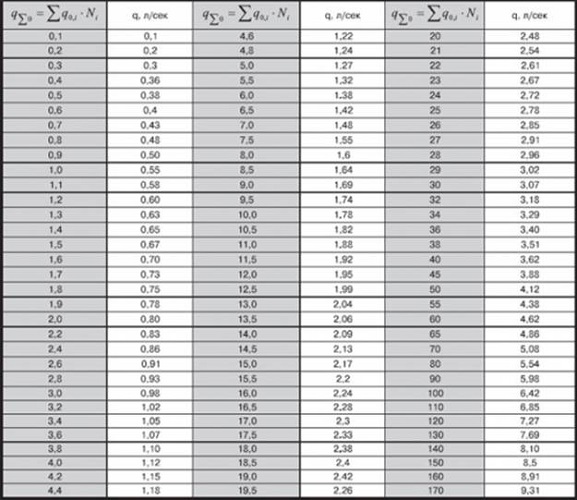

After you sum up the costs of all possible intake points, you should calculate estimated water consumption in the system. This indicator will be significantly lower than what turned out during summation, since the probability of using all water intake points at the same time is extremely low. You can also use the table below to calculate the value.

In the columns with gray fill, the indicators of maximum water flow are shown with a single use of all points of the fence. The columns without pouring (white) indicate the values of the estimated fluid flow, which will reflect the actual water consumption.

Important! Since in the description to the unit its performance is indicated not in liters per 1 second, but in m3/ h, then the number obtained using the table should be multiplied by a factor of 3.6.

For example, the following water intake points are established in a country house:

- toilet with a flow rate of 0.1 l / s;

- washbasin with mixer - 0.12 l / s;

- washing machine (automatic) - 0.25 l / s;

- kitchen sink with a mixer - 0.12 l / s;

- shower cabin with mixer - 0.12 l / s;

- water heater - 0.1 l / s.

Summing up the total consumption from all consumption points, we get: 0.1 + 0.12 + 0.25 + 0.12 + 0.12 + 0.1 = 0.81 l / s. But, since there is a small garden near the house and a plot for a vegetable garden, then the flow rate of the watering tap should be added to the value, which equals 0.3 l / s: 0.81 + 0.3 = 1.11 l / s. Next, we find in the table of the estimated consumption indicator, close to 1.11. Opposite this figure is 0.58 l / s. This number reflects the actual water consumption in this house. The result must be translated into m3/ h: 0.58 x 3.6 = 2.008 m3/ h

Summing up: water consumption in this summer cottage is approximately 2 m3/ h On this basis, it is necessary to select a pump with a capacity of slightly more than 2 m3 / h.

Head calculation

To calculate the head for a submersible pump, the following formula is applied: H tr = N geo + N losses + N free

- H tr - required head.

- H geo - the value of the elevation difference between the highest point of the water intake and the point where the device is located.

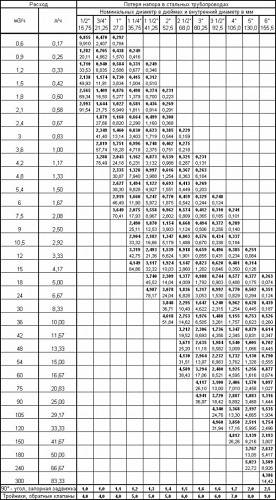

- H losses - total value of losses in the pipeline.Losses can be caused by friction of water in the pipeline, as well as a decrease in pressure in places of pipe bends and in tees. H losses, taken from the tables below. The first table is designed to determine losses in polymer pipes, and the second - in metal.

- H free - is a pressure characteristic that determines the free pressure on the spout. It depends on how comfortable the use of plumbing in the house. For calculations take an average of 15-20 m.

So, to perform the calculation of the pump head, the following data is available:

- well 30 m deep;

- distance to water from the ground surface - 10 m (this is a static level);

- dynamic level (determines how much the water mirror falls when the unit is running) - 15 m;

- the pump is set 1 meter below the dynamic one, that is, at a depth of 16 m;

- the volume of water that will be pumped out of the well - 3 m3/ h;

- the dwelling is removed from the source at 20 m;

- plastic pipe, diameter 32 mm;

- a plastic pipe with a diameter of 25 mm and a length of 15 meters has been laid around the house;

- water intake points are located on the 2nd floor (in this case, the height is 5 meters);

- The system has 2 check valves, 3 tees, 2 angles of 90 degrees and 1 shut-off valve.

First you need to calculate H geo. This indicator is calculated by summing the dynamic level and the maximum height of the water intake point: H geo = 15 + 5 = 20 m. Further, the losses in the system are calculated by summation. In the table of losses for plastic pipes, it is necessary to find a row with a value of 3 m3/ h

Important! It is necessary to take into account the fact that the values in the table are given for a pipeline having a length of 100 m. Therefore, all values will have to be divided by 100.

So, we find in the table the values for a pipe with a diameter of 32 mm (1.54) and for a pipe of 25 mm (2.54). Next, we find the losses for the rest of the system: a valve with a tee have a value of 4, and an angle with a valve is 1. Now you can calculate the loss: (1.54 x 20/100) + (2.54 x 15/100) + (( 3 + 2) x 4) + ((1 + 1) x 1 = 21,689 (approximately 22 meters). Next, substitute the values in the formula for determining the head (H tr = N geo + N losses + N free): H tr = 20 + 22 + 15 = 57 meters. As a result, for this example, you need a unit with a capacity of 3 m3/ h and head not less than 57 meters.

Power calculation

You should know that the calculation of the power of the unit is a rather complicated process using complex formulas and a variety of variables. Therefore, it would be more reasonable to approach this question from the other side: first, you need to calculate such parameters of the device as performance and pressure, and then select the pump model from this data. In the instructions to him and will indicate the power consumption of the device.

Calculation of parameters of the surface apparatus

As already mentioned, pumping stations can work with wells, in which water is at a level of no more than 8 meters from the surface. But when installing the unit should also take into account the distance of the device from the well, depending on the depth of water intake. For example, if water is taken from a depth of 4 meters, the unit can be installed at a distance of 16 meters from the well. For more accurate calculations, you can use the table below.

Performance calculation

For a surface pump, performance is calculated on the same principle as for a submersible unit. How this is done is discussed above.

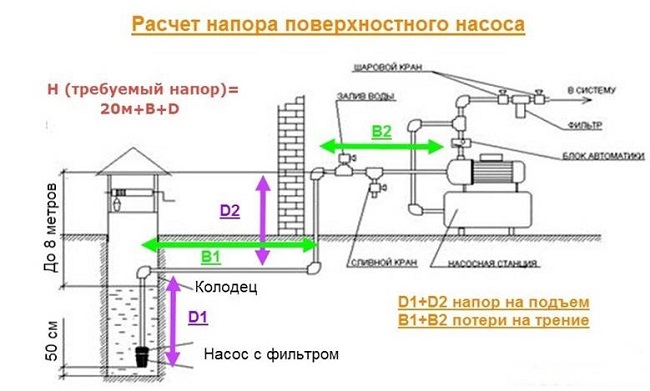

Head calculation

To find out the value of the pressure of the surface station, it is not necessary to do complex calculations. Head is calculated using simple formulas: H = A + B + D. The formula is shown in the following figure:

/rating_off.png)