How to adjust the trimmer carburetor

On trimmers, except electric motors, gasoline internal combustion engines are installed. This mechanism requires special attention, because if it is not configured correctly, it will either refuse to work or will work with interruptions and loss of power. Basically, setting the engine is to adjust the fuel supply, and this is done using a carburetor trimmer.

Content

How the carburetor of the benzotrimmer works

It is almost impossible to cover all the varieties of carburetors produced by the manufacturers of benzotrimmers. But, since the design of this module, as well as its principle of operation is in many respects similar between different models, it is possible to make a generalized description of the processes occurring in the carburetor. This information will allow the user to understand the principles of operation of the device, to eliminate the malfunctions that have arisen and to operate it correctly.

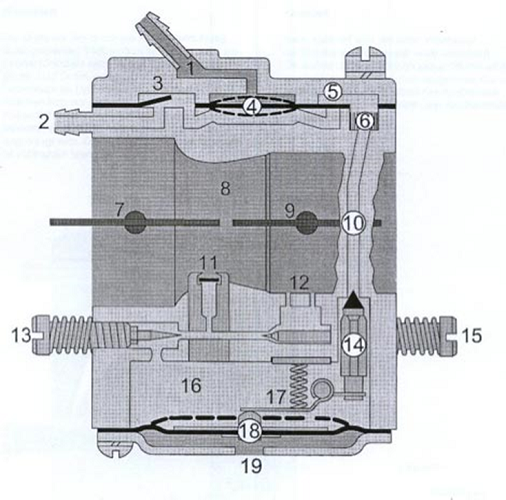

The basis of the carburetor trimmer is solid cast aluminum body. Below is a diagram of this unit.

At the bottom of it, there is a diffuser, which is also called Venturi nozzle (18). Through this nozzle air is drawn in by the motor.

The smaller this hole, the faster the air flows, and the higher will be the level of vacuum in the zone with the smallest diameter.

At the top of the diffuser are fuel channels (11.12). Through these channels the flow of air, tightens gasoline. The fuel pump itself, the nozzles and the system used to regulate the flow of a mixture of fuel with air, can be built-in or installed outside.

Throttle valve (9) regulates the amount of air drawn into the carburetor.Its amount affects the power that the engine develops. The shutter (7) is used for cold start. It must be closed if you are going to start the unit. After the engine has started, it is required to open it, otherwise, the engine will immediately stall.

Pulse channel (1) connects the pulse chamber of the pump with the crankcase of the engine, namely, with its internal volume. The piston located in the cylinder, producing reciprocating motion, sequentially changes the pressure in the crankcase (vacuum or pressure increase). Differential pressure forces the diaphragm (4) to move. Therefore, the pump is synchronized with the engine.

Petrol is sucked from the tank with the participation of membranes (four). Gasoline enters the carburetor through the nozzle (2). Further, its path lies through the inlet valve (3), the exhaust valve (5), through the mesh filter (6), the fuel channel (10), passes by the needle (14) and fills the chamber (16) having the control diaphragm (18) .

The valve (14) is connected to the diaphragm (18) by means of the lever (17). The cavity, which is located below the membrane, connects with atmospheric air through the hole (19).

The device operates as follows.

- A vacuum is created in the diffuser during the suction stroke. This fact causes air leaks. The amount of air entering the carburetor chamber, as well as the engine power and the number of revolutions depends on the position in which the throttle valve (9) is located.

- At this time, the fuel from the chamber (16) is sucked through the nozzles (11,12), after which it mixes with the flowing air. Gasoline, mixed with air, begins to spray. Thus, it is created air-fuel mixture.

- The finished mixture enters the cylinder, where it is compressed by the rising piston and ignites at its highest point from the spark produced by the spark plugs.

- Since the volume under the control membrane (18) is connected to atmospheric air through the channel (19), the membrane moves upwards, opening the valve (14) by means of the lever (17). After opening the valve (14), a new batch of fuel enters the chamber (16).

- After the chamber (16) is filled, the membrane (18) returns to its original position, and the valve (14) closes.

Further, when the engine is running, all the above processes are repeated.To adjust the amount of fuel entering the diffuser through the nozzles, use the screw (13). A screw (15) is also used for setting the idle speed. When unscrewing the regulators, the fuel mixture becomes enriched, and when tightened, the mixture becomes lean. Also in some models of carburetors you can adjust the engine idle quantity control. It is usually located outside and when tightening rests on the lever attached to the axis of the throttle.

Thus, using 3 adjustment screws, you can achieve maximum engine performance, as well as adjust its smooth operation at any ambient temperature, and even in mountainous areas.

Common carburetor problems

Trimmer carburetor breakages occur due to the use of poor quality gasoline, a damaged air filter and the accumulation of dirt in the chamber of this unit. Most often, it is quite possible to repair the carburetor yourself. The following are typical malfunctions of a motokos carburetor.

Fuel pump problems

A frequent malfunction that “chases” the fuel pump is pump membrane deformation. For this reason, it does not fit properly, and the pump channels are not compacted.

Causes of membrane deformation may be the following:

- long work trimmer;

- use of unusable fuel;

- gas in the pulse channel.

As a result, membrane damage reduces pump performance, and, as a result:

- depletion of the combustible mixture occurs;

- difficult to start the engine;

- there are interruptions in the work of the motor;

- damaged piston.

Also, the consequences for the engine described above may cause the pump cavity to become clogged with impulse side. In this case, the dirt enters the membrane through a pulse channel.

To eliminate the clogging, you have to disassemble the carburetor and clean the membrane.

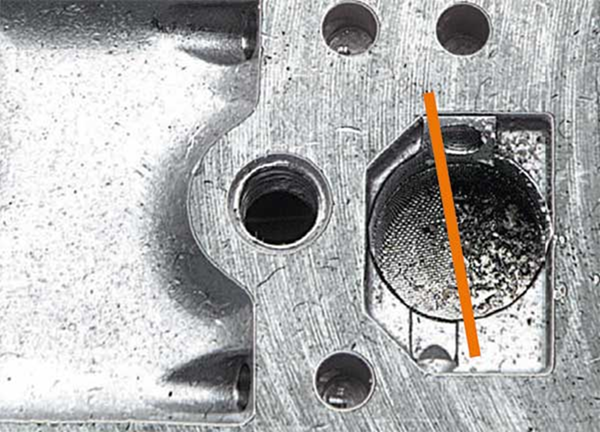

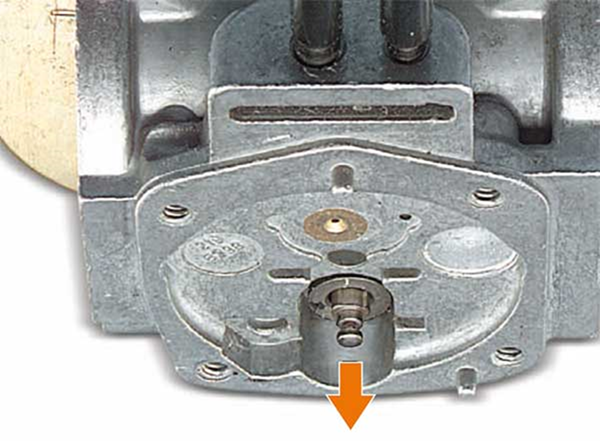

Mesh filter clogging

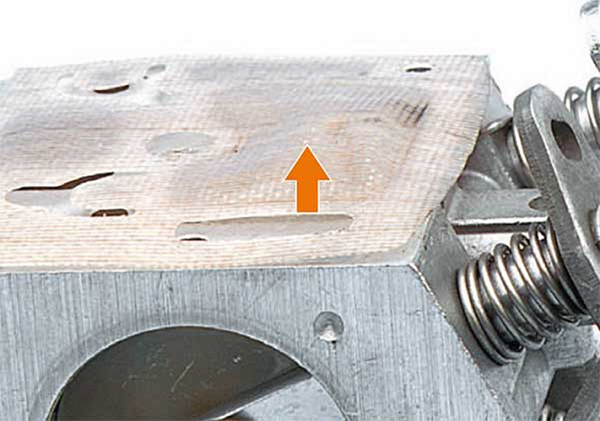

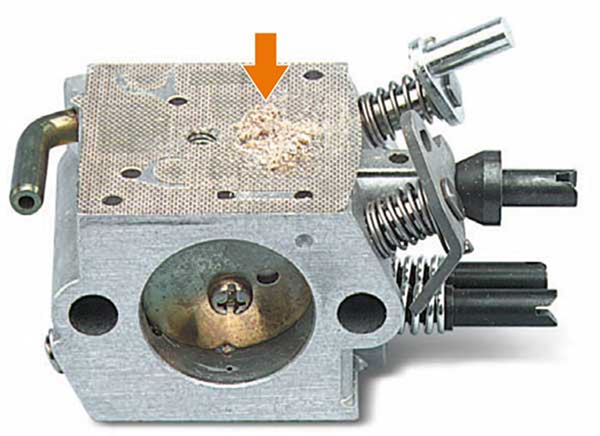

The strainer may be contaminated when contaminated fuel enters through a fuel hose or a suction head that is defective. In the photo below you can see what a clean filter looks like and a dirty one (the parts are separated by a dash).

To eliminate the problem, thorough cleaning and washing of the strainer will be required. Also recommended blow through with compressed air All holes in the trimmer carburetor body.

Faulty adjusting lever

This breakdown occurs when the contact surface of the lever wears out.

Erase contact surface occurs due to the presence of gasoline abrasive particles or due to strong motor vibration during operation. This defect of the adjusting lever causes problems with the intake, as well as incorrect operation of the engine at idle.

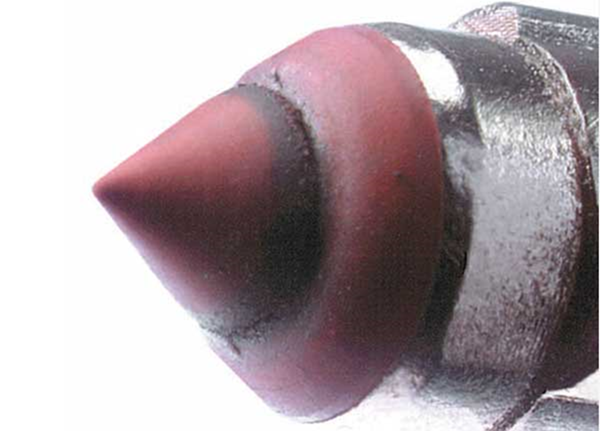

Wear needle

The inlet needle fails, as a rule, due to the presence of abrasive particles in the composition of the fuel fluid.

As a result:

- ensure the tightness of the inlet needle seat;

- there is a leakage of the combustible mixture;

- engine malfunctions due to the re-enrichment of the fuel mixture.

Also, the intake needle can simply jam.

Sticking of the inlet needle can cause the presence of dirt in fuel, or a long simple apparatus without work.

Congestion blockage

If dirt accumulates in the adjusting cavity, the inlet needle cannot lock the hole tightly and pours a lot of fuel into the chamber.

It causes fuel re-enrichmentand the engine starts to work incorrectly.It is necessary to disassemble the carburetor and clean the cavity of the adjustment membrane.

Deformation of the adjustment membrane

The membrane may be deformed during long-term operation of the unit and when using aggressive fuel.

The impossibility of normal adjustment due to a defect leads to:

- piston damage;

- difficulty starting;

- fuel depletion;

- engine malfunction.

The problem with the intake adjustment lever

This problem may occur if the adjustment lever is installed incorrectly or bend it before installation. As a result, the contact surface takes the wrong position, which violates the additional fuel supply.

Wear flaps

The throttle and air dampers mainly wear out due to the presence of abrasive particles in the air. Defective flaps appear as if they have been sandblasted.

As a result of wear of the dampers, the engine performance decreases, there are malfunctions in its operation, piston rings, piston and cylinder cover wear out.

Worn throttle and choke shaft

The air and throttle shaft may wear out for the following reasons:

- insufficient and improper maintenance of the air filter;

- the air filter is damaged;

- The air filter is not suitable for this unit.

Due to hit poorly purified air, the shaft wears out and can break. Broken shaft parts can get into the combustion chamber or engine crankcase and cause serious damage to the entire piston system.

To eliminate problems with air purification, it is necessary to replace a defective filter or flush the existing one (serviceable). The filter should be washed in soapy water and dried.

When it is necessary to carry out adjustment

Adjusting the carburetor is necessary in the following cases:

- The new engine was tested (used 4-5 liters of the fuel mixture);

- changed the composition of the fuel (brand of oil and gasoline);

- the weather changed (it became hot, cold);

- the vacuum of air has changed (concerns mountainous areas);

- after prolonged storage;

- increased load on the engine (after a tool change, etc.);

- due to the vibration, the adjustment screws spontaneously unscrew;

- increased fuel consumption, carburetor pours fuel;

- carbon deposits quickly appear on the spark plug electrodes (the fuel mixture is prepared correctly);

- the engine starts and immediately stalls or badly gaining momentum;

- no gas enters the cylinder;

- large amounts of exhaust gases.

How to make adjustment

Before you begin setting the trimmer carburetor, you must do the following:

- flush the engine;

- replace or clean the spark plug;

- change to a new one or clean the air filter (it is recommended to wash it in warm, soapy water, squeeze it out and let it dry well).

Also needed set cord suitable diameter trimmer coil or install knives - this is done so that in the process of tuning the engine had at least some load. After installing the cutting tool and starting the gasoline engine, let it warm up for 10 minutes.

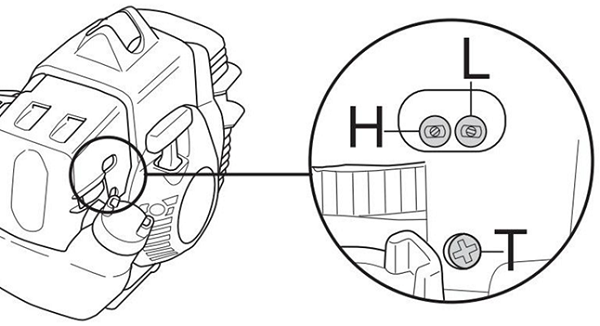

If a at idle motor you noticed that the cutting tool rotates, which means that it is necessary to reduce the engine speed. This is done with the help of the lower idle speed regulator, often marked with the letter “T”. The figure below shows the placement of the knobs on the Husqvarna trimmer.

But, for example, on a Stihl trimmer, this screw may be marked “LA”.

So, turn the idle speed control to the left until the trimmer head stops completely.

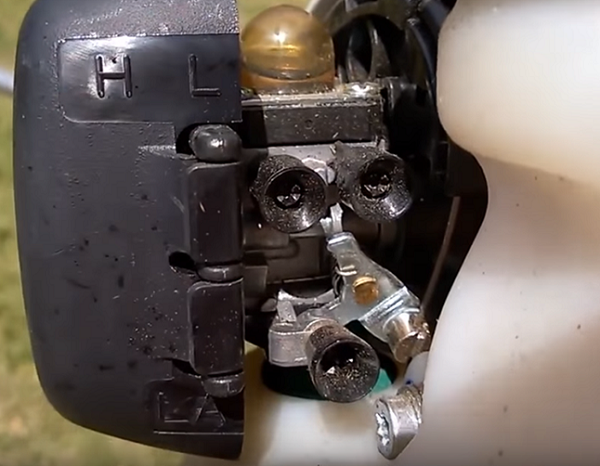

To adjust the carburetor used 3 regulator (screws).

- Right knob L adjusts the level of enrichment of the combustible mixture at low speeds. It needs to be adjusted first. Achieve maximum idle speed. This is done using the L adjuster, turning it left and right. After finding the point of maximum revolutions, return the regulator half a turn to the left (against the hour).

- Lower regulator T (LA) used to adjust idle. Turning it to the left, the engine speed will begin to decrease, and when you turn the regulator to the right, the engine speed will increase.

- Left control H responsible for the enrichment of the combustible mixture at high speeds. The enrichment setting completes the carburetor adjustment. Also with the help of this regulator you can adjust the maximum speed, fuel consumption and engine power.

Important! If you allow the engine to work at full speed for more than 10 seconds, then it can fail.

To eliminate this trouble, adjustment will be required.With the engine running, turn on the full throttle, then turn the “H” control to the right until the reduction in speed begins. After that, the “H” knob must be slowly scrolled to the left until you hear the uneven engine operation. Then turn the “H” knob to the right until the moment when the smooth operation of the motor is heard.

After performing the above steps, the carburetor setting can be considered complete. After correct adjustment, the engine should confidently gain momentum, barely quadruple at maximum speed, and when idling, the cutting tool should not turn. This guide is suitable for adjusting carburetors on Huter, Patriot and other gas mowers.

Also exist carburetors without screwresponsible for the enrichment of the combustible mixture at low revs. That is, they have only 2 adjusting screws: a regulator of idling and a regulator of the quality of the fuel mixture at high revs. How to configure this type of carburetor, you can learn from this video.

The most popular gasoline trimmers 2018

Trimmer UNION BTS-9252L

Hammer trimmer MTK33LE

Trimmer Interskol KB-25 / 33B

Trimmer Carver Promo PBC-43

PATRIOT PT 3555 ES trimmer

/rating_on.png)

/rating_off.png)