Replacing disc trimmer

Replacing the disc with a trimmer will need to be done regularly with frequent use of a benzokosoy. Even good knives become dull with time, you need to sharpen them or install new ones. In practice, plastic and metal discs are used, having a different number of blades, sharpened differently. The procedure for replacing does not depend on it. In the process, the important point is to comply with safety regulations. If the material of the cutting part of the tool allows, you can independently perform the sharpening, which will save money.

Content

When to use a disc, not a fishing line

For owners of cottages, land, lawn lovers, the trimmer is an assistant that speeds up the routine work.During the operation of the tool, a number of questions arise related to the fact that it is preferable to use the nozzles, how to replace them independently.

When working with benzokosoy often use fishing line, which is cheaper than discs. In addition to the price, it also has the following practical advantages:

- can be used with a large number of trimmer heads;

- fishing line is safer when working than discs.

Lack of fishing line is that it is only suitable for mowing low grass, because otherwise it is often clogged. This is typical for both electric and gasoline braids. When the grass is wound on the spindle, a large resistance occurs on the shaft, and it is damaged. At the same time, the piston system (in gasoline mowers) can also fail or overheat and burn the electric motor (in electric braids).

In some cases knives are more efficient. They are used for mowing:

- high and coarse grass cover;

- weeds;

- shoots of trees;

- home (for example, raspberries, currants) and wild (dogrose) bushes.

Thanks to the use of knives, the tool wears out more slowly: this is due to the factthat he is less clogged.

Cutting attachments of this type are also differently called discs or cutters, the essence does not change.

Which knife is better

Modern manufacturers offer consumers a wide range of discs. Cutting parts are classified according to the following criteria:

- material used for their production;

- the shape and number of blades.

Material

The material for the knives is plastic or metalwhat determines their purpose. Naturally, the question arises as to which disc is better to use: plastic or metal? The choice is determined by such factors:

- the area of the site intended for mowing grass;

- type of tool (electric or gasoline).

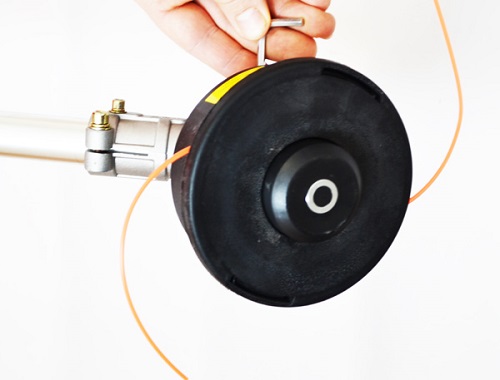

Three-blade plastic knife for electric trimmer

From the point of view of safety, steel mills are not recommended to be installed on electric braids - they are almost always equipped with plastic blades. The design features of the power tool itself, its technical characteristics make the installation of metal cutting parts dangerous:

- the presence of a curved bar;

- Often there are no stops on the handles of electric braids;

- high speed of rotation.

According to the rules of safe operation, plastic knives are applied only on braids with flexible rod. Plastic blades are designed for mowing soft plants (eg, burdock, nettle), dead wood. A metal disc cutter is used for mowing thick, high, coarsened grass, shrubs and shoots of various trees, because its cutting properties and wear resistance are higher than those of plastic analogues.

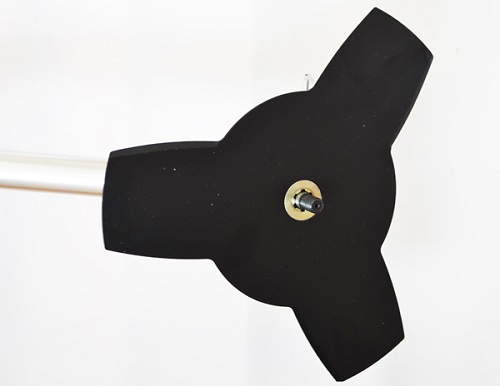

Carbide tipped trimmer for 40 teeth

The device, as well as the technical characteristics of the benzocos determine the use of metal nozzles when working with them:

- the presence of a straight bar increases the distance to the mower's legs;

- comfortable handles with limiters;

- the possibility of a smooth set of revolutions.

Petrol units equipped with metal discs are well suited for mowing large areas with different grass or shrubs.

Metal knife on benzokose

Number of blades

The shape of the disk blades practically does not affect the quality and speed of work, their number matters. For harvesting hay It is recommended to use cutters with a large number of blades, for example, with 8 or 4 main and 4 additional blades. If there are few of them (2, 3), then such knives chop the grass very strongly. Mills with a large number of small teeth are used when mowing young shoots trees and shrubs.

Patriot PT453 benzokosa with metal disc for mowing bushes

Metal knives for benzokosa are sharpened in different ways: one-sided and on both sides. Dull cutting edges with poor sharpening reduce the productivity of work and also degrade the quality of work. This increases the load on the tool and fuel consumption.

The collision of knives with stones is dangerous, as a result of which the tool bounces off, which may cause injury to the mowers.

Select the cutting element for the trimmer on the material, size, design should be based on the type of tool and the power of its engine, the amount of work to be done and the type of plants to be mowed. In part, this will help the manual from the manufacturer to the model used - there are prescribed recommended parameters of the cutters.

The algorithm for installing the knife on the trimmer

Replacing the knife on the trimmer is quite simple. Manufacturers include with it key to remove the cutting nozzle (spools with fishing line) and a pin designed to block the gearbox. To change the disk, you must perform the following steps:

- remove the protective cover;

- insert the pin into the aligned holes located on the shaft and the gearbox, and thus block the drive;

- if a spool with a fishing line is installed, then unscrew it in a clockwise direction and find the nut to tighten the knife;

- install disk;

- put the boot;

- blocking the gearbox with a pin, tighten the nut for fastening, tightening it with a wrench;

- to fasten a casing.

The algorithm for installing the knife on the trimmer is shown in detail in the video below.

Modern trimmers, for example, from the company "Shtil", easy to maintain. It is easy to carry out the replacement of the cutting parts yourself.

When working should pay attention to safety, so as not to cut yourself.

How to sharpen the disk if it is blunt

Motor-mowers are designed for mowing grass, shrubs and young shoots of trees. From the sharpness of the blades depends on the quality and productivity of work.Over time, knives become dull, even with pobedits. In this case, you can go two ways:

- buy a new cutter;

- Sharpen your old blades without soldering.

To properly sharpen knives, proceed as follows:

- gently disassemble the trimmer, while removing the cutter;

- inspect it for the presence of cracks that make further operation impossible;

- if the blades are bent, they are aligned using a hammer;

- hold the blades firmly, not too hard, but so that they do not move;

- based on the size of the disk, choose a file on the metal, so that it was convenient to work;

- to the same degree (at an angle of 30 degrees) they sharpen all the cutting (upper) edges of the knives;

- in the reverse order collect benzokosa.

Soldering discs from solid materials only change to new ones, but they do not sharpen.

Sharpening can be carried out on an emery machine at low revs - this will speed up the workflow. For this, a grinding wheel with an average grain size is used. Sharpen knives should be, wearing gloves and glasses.

For motokos used plastic and metal cutting nozzles with different number of blades and sharpening.These factors determine the scope of application of knives. Therefore, you should select them, given the nature of the upcoming work. Replace and sharpen trimmer discs carefully to avoid injury. There is nothing complicated about it. Only there may be a different way of fixing the cutters on older models, so you may need to use another tool.

/rating_on.png)

/rating_off.png)