Independent repair of electric convector

With the onset of cold weather, you remembered that somewhere in the pantry should be electric convectorwhich perfectly complemented the central heating last winter. When you turn on the network, the device does not show signs of life, although there is current in the network? This means that the reason why the convector does not want to heat the room is hidden inside the appliance. Do not rush to call the master - repair of the convector is quite possible to do it yourself.

Content

We check internal connections

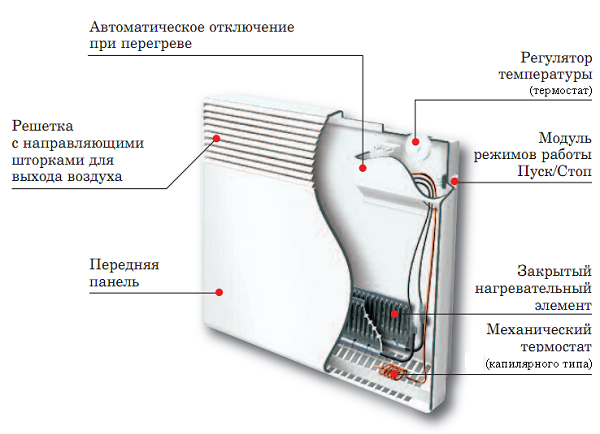

Before opening the convector, it is necessary to read the instruction manual, find the detailed scheme and study it thoroughly. The design of the convector is quite simple, and you can understand it without technical education.

Tip! Before turning on the device, it is necessary to vacuum it, or rather, to blow it out, directing a stream of air inside the device to remove a layer of dust from the heating elements.

First you need to check power buttonif it is working, then we move further: we remove the front panel of the device to open access to the internal device. Visually check all the wires that are suitable for the terminals - we are looking for signs of burning or loosening in the tightening of the fastening screws that attach the installation wires. If a screw is found, weakened due to a broken thread, then change it to a new one and tighten it. We remove the found scale, we clean the wire connection place, having disassembled the connection. This operation must be approached thoroughly: sanding down the washers and bare part of the wire with emery paper, then reassemble everything, firmly tightening the screw.

Then check with a multimeter Temperature regulator. In electric convectors of different models, this particular switch of mechanical action can break.

Thermal limiter

Its task is to automatically turn off the convector when the inside temperature limit set by the manufacturer is reached.The contacts of the emergency thermal limiter are always closed, which is easy to check with a probe.

Upon detection nagara, it is removed, and in the case of the formation of sinks at the contacts, they must be filed with a file, then degreased with B-70 gasoline. All operations must be done carefully so as not to disturb the bimetallic plate and not knock down the factory settings.

If the thermal limiter cannot be repaired, then it must be replaced with a new one in order to protect itself against various troubles associated with overheating of the electric convector.

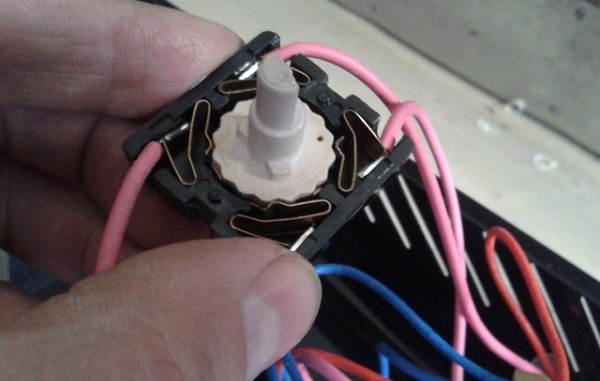

Check switches

If on the convector, besides the power button, there are other key mode switches and the like, you need to check their serviceability. We set the “On” position, we check with ohmmeter the conductivity of each switch in turn, touching the probes of its contacts.

Having detected a malfunction, try to remove it by the method. stripping contacts, and if the breaker breaks, it should be replaced completely.

Check switch contacts

Heating elements

If all the switches are intact, the cord is whole, and the convector still does not work, then the fault may be in the fault heating element. They are used in modern convectors from one to three at a time.

To check the integrity of such an element, we use ordinary multimeter: we apply one probe to the mounting point, and the second in turn we touch the other conclusions on the elements. Often, good contact is prevented by a layer of formed scale or foreign dirt. We clean all contacts, assembly wires to a glittering shine and repeat the measurements. When the cause of the malfunction has been identified, we try to repair the heating element, if this is not possible - it must be replaced.

Heating elements are applied in two types - closed and open type.

Open TEN

This type includes heating elements:

- a spiral stretched between ceramic planks;

- nichrome wirespiraling with strung ceramic beads;

- core of ceramic, which is tightly wound nichrome thread.

Separate blocks are created from open heating elements along with heat shields.

Open heating element

Closed teny

Such heating elements consist of a helix enclosed in a hermetic glass tube made of transparent glass, which perfectly transfers heat, but also serves as dielectric. These include hermetic tubular type electric heating elements (heating elements) - in them the coil is enclosed in a steel sheath, and the quartz sand, tightly packed inward, serves as a dielectric.

In many imported convectors it is possible to find heaters that are formed by applying a coating that conducts current on a special hardening glass or a very thin wire woven into a heat-resistant fabric.

Closed heating element

Such elements are not repaired, but are replaced with new ones. repair kitif the manufacturer has taken care of this. In the absence of spare ones, it will be necessary to select from domestic ones - this is where knowledge of the fundamentals of electrical engineering will be needed. It is better to entrust such nuances to specialists from the service center, otherwise you will have to buy a new convector instead of a burned out one because of your lack of competence.

Heater Replacement

It is easy to make repairs by hand with convectors if there are domestic heating elements inside. If they open type, it can be repaired according to the following procedure:

- Remove the helix from the strip.

- Measure its length and wind a spiral of nichrome wire of the same cross section.

- Put the helix on the ceramic strips (put on the protective beads made of ceramic).

- Set to its original place.

At the same time, we should not forget one feature of nichrome - when heated, the thread lengthens and sags, so when installing it, it is necessary to slightly tighten it to eliminate the dangerous touch of the metal parts of the case.

Closed types of heaters they change in the same way - a burnt-out spiral is removed from a hermetic glass flask, and instead of it we insert a new one. But first it must be rinsed first in gasoline to remove the lubricant - only after that you can proceed to the final assembly with all the precautions.

If the heater is installed in the convector, then your task is to accurately establish its inoperability, and the replacement is carried out even easier than in other cases. A new heating element is installed in the place of the blown-out heater with the subsequent connection of conductive wires.

Heating element repair

Operating rules

Many users are sure that they know these postulates, but in fact, convectors are often incorrectly used, which contributes to the rapid deterioration of expensive equipment. Follow the simple recommendations of manufacturers - this is the key to the perfect service of convectors for a long time.

- Never cover the case with clothing or a veil - a violation of air circulation occurs, which guarantees equipment breakage.

- Do not dry wet clothes on the convector - for this there are special folding devices.

- For rooms with high humidity it is necessary to use models with the IP 24 sign.

- Remember that the body of the convector is not protected from mechanical impact; with an external impact, anything inside the device can break - from a simple sensor to an expensive heating element.

- Do not use carriers that are not designed for the power of your convector, they may burn out and cause a fire.

- Do not allow children to operate the device in order to avoid accidental burns.

- Do not touch the product switches with wet hands - the risk of getting an electric shock increases dramatically.

- Eliminate the risk of small objects getting inside the convector.

The product will serve for a long time and will not let you down during operation, if for a period of temporary non-use during the summer period, you will pack it in plastic bag and put the box in a dry place. The eternal enemy of such devices - dust - will not be able to penetrate into the body and accumulate on the heating elements.

To increase the tightness - connect a vacuum cleaner to the bag for a short time, it will suck off excess air, you will get 100% insulation.

/rating_off.png)