Tubular heating elements for boilers

The tubular electric heater - TEN invented in the middle of the XIX century, for 158 years of its existence, it has become an indispensable element of many household appliances associated with the active heating of water. The heating element for a water heater is the main part - without it, normal operation of washing machines and dishwashers is impossible, no electric boiler can heat water in the absence of this component.

Content

Purpose and variety

For any water heater TENY are the main part. They work from the electrical network, so the designers use them in the development of various electric heaters from a regular kettle to automated high-capacity boilers.

TEN for a water heater constructively represents a hermetically sealed copper tube with a spiral of nichrome inside, which is usually located at the bottom of the product or, in exceptional cases, on the side. The lower location is more acceptable because it provides uniform heating of the entire volume of water.

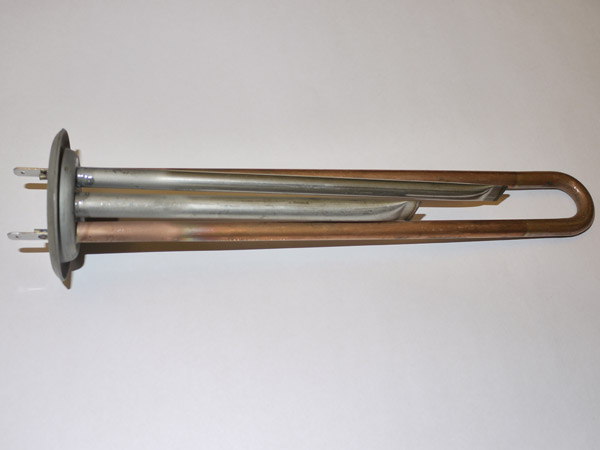

Depending on the design, the heaters are divided into “dry” and “wet”. The first so-called due to the fact that they do not have contact with water - their body hides hermetic flask. Water heaters with dry teng used for modern models. Manufacturers consider such a design more durable, since the casing of the heating element is not subjected to constant exposure to water - the absence of limescale deposits and scale significantly extends the life of the heating element. They will not burn out if the user accidentally turns on the boiler without water.

Dry TEN

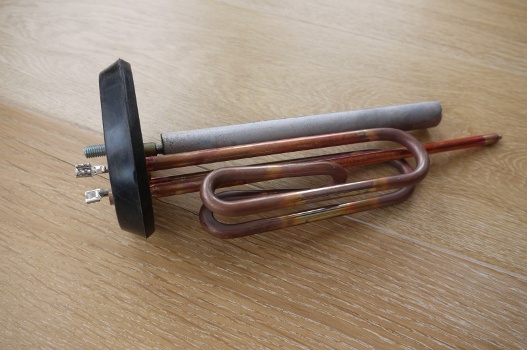

However, the most common model is considered wet or submerged heaters. Some users believe that this is an outdated model and in vain - they continue to be widely used in various water heaters.The main disadvantage of such a heater is the tendency to frequent breakdowns due to scale and deposits, but compared to a dry counterpart, they are easier to find on the market, easier to replace and they are naturally cheaper.

Wet TEN

Design features

The standard design of a wet heater consists of the following elements:

- hollow copper or stainless steel tubes bent in different ways;

- inside there is a spiral of nichrome filament;

- An insulator is a heat-conducting substance - quartz sand or magnesium oxide.

Dry or closed heating element for a boiler is characterized by the presence of insulating flask from ceramics of increased strength. Sometimes its body is made from magnesium silicate or inorganic steatite, but not from metal. Heating takes place through this protective flask, and the tubular element itself does not come into contact with the aqueous medium, therefore it lasts a long time.

If you talk about which types of heating elements are better, then it should be immediately noted that there are very significant differences in power and configuration - for wet elements there are differences in the applied fastening, bending shapes and materials for making the case. The type of tank used in the boiler determines heater shape - according to this characteristic, the electric heater can be made of a direct view or bent, in various directions. In the main body TEN wet type is made from copper and stainless steel. Dry heater for installation in the boiler is made in the form of a straight rod of different lengths and diameters - it depends on the volume of the tank, the body is made of stainless steel, and the satatite coating is made specifically for each model.

Difficult choice

When users buy a water heater, a natural question arises as to what type of heating element would be better for a boiler. To do this, it is necessary, at a minimum, to familiarize yourself with their performance characteristics.

Standard installation of all heaters in products is of flange type. In this way, full contact with the heated liquid is achieved, but deposits and corrosion products, significantly slowing down the effect of heat transfer.

The heating process increases with the time of operation, which leads to an increase in power consumption. Designers from different manufacturers use various modifications that slow down the occurrence of deposits and scale,but wet fuel elements tend to quickly fail, and maintenance of them is quite difficult.

Dry heaters have a longer service life due to the fact that their case almost never comes into contact with heated water. The inner part of the tank capacity, as well as the flanges of the heaters, is covered with special enamels based on titanium or glass ceramics - such protection against corrosion prevents the occurrence of deposits and scale.

With long-term operation, wet-type thermal heaters are overgrown with scale, which can lead to a breakdown, and the user will receive an electric shock through the body of the product. In the dry version, this negative possibility is eliminated, because between the fluid and the heater body is installed ceramic flask, which is dielectric. In addition, this option completely eliminates overheating of the heater body, service is reduced to a minimum, but periodic replacement is not excluded, although much less often.

Many manufacturers have established production of water heaters of a large displacement using two types of heating elements at once, which contributes to high reliability and increased service life.

Statistics confirm that closed heating elements are operated three times longer than their open counterparts - wet ones serve no more than 5, and dry ones are at least 15 years old. The cost of open heaters is much lower, they are more practical for repairs, but if you do not plan maintenance of your water heater, it is better to opt for the dry option.

What are the heaters

Different models of water heaters are different heating devices, so you need to know their features in order to choose for your boiler identical heating elements.

Ariston

The famous concern from sunny Italy prefers heaters from stainless steel with chromium-nickel compositionbut with a copper sheath. The flange is made of brass - this contributes to an increase in thermal power of at least 1.5 kW. TEN of such performance are used in all water heaters, both small-capacity types, and folios, designed for more than one hundred liters. The cost of a new similar element is in the range of 1.5-2.0 thousand rubles.

Thermex

Another Italian company supplies its products immediately. two types of heaters, which significantly reduces the time of heating water - one with a power of 1 kW, and the other 1.5 kW. They work together or separately, which allows the user to adjust the heating process at his discretion. The body is made of an alloy for which there is a registered patent, the composition is kept secret. A big plus - instead of them you can put the heater from other manufacturers, for example, Atlantic or Garanterm.

Combustion

The Slovenian company uses tubular type heaters, but covered with protection from vitreous glaze or glass porcelainsimilar to enamel covering the inner surface of the container. Thus, developers are successfully struggling with the emergence of scale and limescale, which leads to frequent breakdowns of this part. Water is heated to an optimum temperature of 90.0C, therefore, when replacing and installing a heater from another manufacturer, the user should be reduced to 60 degrees so that the heater does not burn out.

Problems

We give a short list of common faults in the operation of heating elements.

- When cold water is running from the tap, it is a signal that a violation has occurred in the heating element connection - a thermostat.

- If the product turns on and then turns off - this is the first signal that a rather thick scum or a layer of limescale.

- When a user made various errors due to inexperience during self-installation, a very impressive air bagwhich does not allow TEN to heat water.

Any malfunction is much easier to prevent than to eliminate by applying certain efforts and financial injections.

Replacement Algorithm

Replacing the heating element in a water heater is a very labor-intensive operation and it is carried out strictly according to certain regulations:

- disconnect the product from the mains;

- make a complete discharge of water;

- remove the water heater from the fixings and turn it over for the convenience of all work;

- unscrew the fastening of the bottom panel, take a picture of the location and procedure for connecting the wiring;

- disconnect the wires from the heating element and remove it from the tank body;

- clean the scale and scale, if no damage to the body is found, then install the heating element in place;

- in case of replacement, we install a new heating element, do the assembly in the reverse order.

Especially for inexperienced users, to help them carry out such an operation correctly, there is a video story, where an experienced master replaces the heating element in a boiler:

/rating_off.png)