How to care for a sewing machine

A sewing machine is a very sensitive home appliance. The slightest disruption in the work of its parts can lead to failures or even serious damage. Each owner should pay special attention to the maintenance of the sewing machine and the maintenance of the unit, namely cleaning and lubrication.

Content

How to clean and lubricate

If you notice that the old sewing machine has started to act up: it skips stitches, does not work with thin threads, and deforms the fabric, then it’s time to do a technical inspection. Consider the process of disassembling, cleaning parts from dust accumulations and lubrication on the example of an ordinary home sewing machine Janome (Janome). There is no fundamental difference in the internal structure of these devices, so the instructions given here are relevant to any models.Of course, specific devices or devices may be added to individual devices, but these are special cases. Let us consider what anyone can repeat at home.

What you need to work

For the procedure, you will need to stock up a certain set of tools and materials.

- With a lint free cloth, any cotton rag is perfect.

- Brush with a hard nap. Usually, a toothbrush is used for these purposes, but artistic brushes also do an excellent job with the task.

- Oil for sewing machines.

- WD-40, you can ask in automotive stores. This is a special substance, with the help of which the moving part of any mechanism is usually lubricated. It is sold in the form of an aerosol.

How to lubricate the home sewing machine in hard to reach places? Professionals usually use a 5 ml disposable syringe, which can be purchased at any pharmacy. His needle allows you to penetrate the smallest holes and dispense oil.

Stepwise Algorithm

We proceed directly to the procedure.

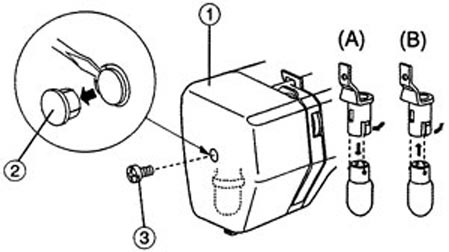

- Unplug the device from the outlet and remove the needle from the mount - it will save you from accidental injuries while working.After that, look for the screw on the front of the case, it is usually hidden under a decorative cap.

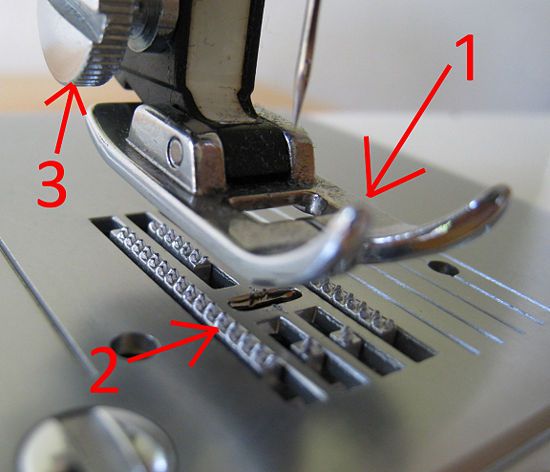

- Remove the cap and unscrew the screw with a screwdriver. Then you need to unscrew the mounting screws at the strip of the rack and pinion mechanism that performs the function of moving matter. The released plate should be pulled out, and how to clean the space under it.

- The next step involves hard work. It is necessary to remove dust from all connections that you can reach safely. Remove from them the old oil to lubricate home sewing machines and apply a new layer. Distribute the substance carefully using an oilcan. For each connection will be enough two drops of oil. Blot down any excess with a cloth and wipe off any traces left. To evenly spread lubricants, slowly rotate the drive wheel.

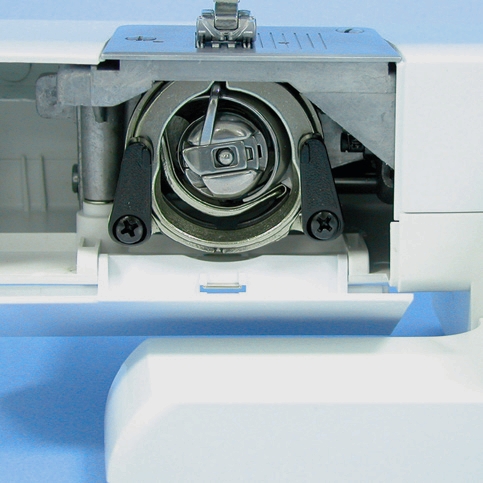

- In the next step, it is necessary to squeeze the mounting mechanisms of the shuttle, and carefully pull it out of the slot. The operation is completely carried out manually, additional tools will not be useful to you.

- Apply the required amount of lubricant on video. This part should rotate well, so as not to impede the movement of the shuttle.Also carefully treat shaft attachment points. Some models may have gaskets of felt and felt there, do not be surprised and do not rush to pull them out. These parts are designed to absorb the oil for sewing machines, which turned out to be superfluous and flowed out of the knot.

- Check the operation of the hooks securing the hook mechanism. They should move easily, not jam and not create obstacles.

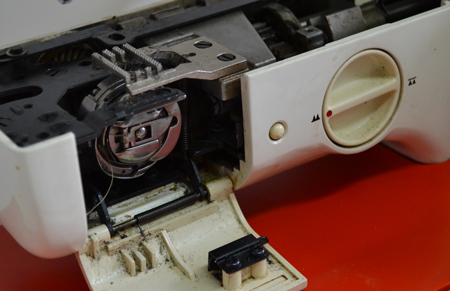

- Like previous nodes, your attention requires the carriage and the plate that fastens it. Simply remove the part and scrape off a layer of old oil and dust. After that, the carriage is greased with a thin layer of fresh grease and put in place.

- Under the plate of the mover fabric usually the most dirt and dust. She gets there with a piece of material that passes through the foot with the needle. Use a toothbrush and carefully clean out all the debris that has accumulated during the work. Pay special attention to the rubbing parts - you must erase the old layers from them. How to lubricate our sewing machine in this place? Using a special grease gun or syringe. In this segment, you need to be even more careful, because the leaked oil does not necessarily get on the threads, and then on the fabric of the product.

- Do not deprive of attention and shuttle. Thoroughly clean all its elements from dust. This can help a dry brush for painting with a hard pile. Do not use a damp cloth or wipes with a cleaning solution - this may damage sensitive parts.

In all this work, a substance called WD-40 will serve you well. It perfectly removes old sewing machine oil and dust accumulated in the mechanism connections.

The cleaning procedure for a sewing machine can take quite a long time. If you are not ready to spend it or are not confident in your skills, it is better to call the master. Mistakes during assembly and disassembly, as well as inaccurate handling of small parts can lead to malfunctions in the future.

Lubrication features

The biggest mistake is the opinion that the oil for sewing machines should be applied in large quantities. In this situation, more is not better. During use on the internal parts of the device accumulates an impressive layer of dust that gets there with the cloth. Over time, this may cause problems with the advancement of the web. In addition, deposits of dirt on moving parts create a serious load on the drive device. The excessive amount of oil applied by the generous hand of an ignorant owner accumulates the smallest pieces of matter, scraps of thread, dust. Falling into lumps, this mass accumulates in one place, causing problems with the sewing machine.

How to choose oil for lubrication

Sewing machine oil possesses viscosity index. Applying an unnecessarily thick, you risk not smearing the internal parts of the mechanisms, which are the main friction. Taking a more fluid, again you can be left with nothing, because it simply flows down, and the mechanisms again, do not get a lubricant. Lubricant for the average household sewing machine should have a medium viscosity. Usually this indicator is listed directly on the label. It is worth noting that oil for industrial sewing machines is sometimes not necessary at all: high-quality professional units are equipped with an automatic lubrication system.

Which oil is the best? The one that comes with the machine. If it was not originally, then choose a special lubricant of only the best quality. Its cost can begin from 100 rubles and above. It can be sold with special oiler and in a simple plastic bottle.

Do not even think about using car or vegetable oil - it is strictly prohibited, as it has a detrimental effect on the functioning of the entire system.

Experts do not recommend saving in this matter. Cheap oil may smell unpleasant, dry out quickly, or clump together. This oil is not recommended to be stored for a long time after opening. You can use it only if nothing else was at hand.

/rating_off.png)