The role of the shipping bolts in the washing machine

Transportation of household appliances from the place of assembly to the buyer is carried out in special conditions - using a safety frame and packaging materials. But if for a simple technique there is enough elementary foam protection, then a washing machine requires a more careful approach. Surely many have heard about the shipping bolts on the drum, which need to be removed from the washing machine before its operation. We will find out exactly where they are and how to dismantle them correctly.

Need to use

The household appliance is designed in such a way that there are moving parts inside. In fact, the drum moves almost randomly along the body of the washer. If you do not fix the device with special bolts, then during transportation the drum may damage the walls of the machine or break completely. Transport parts in this case play the role of a kind of fuse that protects the internal parts.

At the time of final delivery to the place of future work there is a need to connect the device to the network and drain. Only by doing this, you can fully use all the functions of the machine. During the installation work, it is necessary to remove the shipping bolts in the washing machine, otherwise they will violate the algorithm of washing and spinning. Starting the device with the installed transport parts is strictly prohibited - this may entail serious violations that are not subject to warranty repairs.

Location

Basically, the popular models of the washing machine are designed the same way: the shipping bolts they have are on back wall. Exceptions are some devices, the loading hatch of which is located vertically. In them, transport bolts can be installed in the top cover, but this is quite a rare phenomenon.

Mounts

Some basic differences from standard bolts shipping do not possess. They can be a bit larger, and always equipped plastic insert special form. The insert secures the drum in one position. The immobilized drum does not respond to the roll and vibration that accompany it throughout the journey. The general principle of the design is to securely fix the drum by pressing it against the back panel.

To immobilize him in this way, usually between three and six bolts are enough.

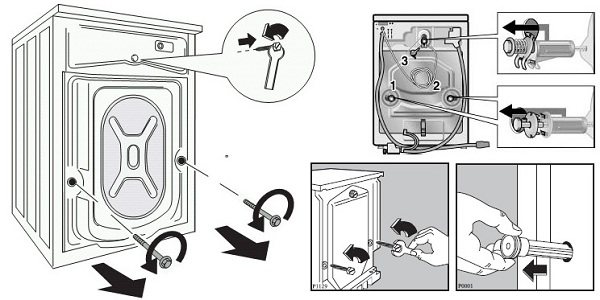

Disassembly instructions

To dismantle the transportation parts at home is very simple. This requires a simple wrench or versatile tool with customizable size. Ordinary pliers can also be used. Dismantled bolts are recommended to be maintained throughout the entire operation of the device. If you need to transport the car to another place, they can be easily installed back.

For dismantling, you can use a key in the size of ten to fourteen (depending on the brand).

Himself dismantling process as follows:

- ensure free access to the rear panel of the unit;

- loosen the fasteners by turning them counterclockwise with the selected key;

- remove bolts by hand;

- removing the mount, do not forget to put the plastic parts provided in the kit.

The task of these caps - protect the openings from contamination and foreign objects. In the case where the developer has not provided any special parts, thread protection is optional. If you have any problems with the dismantling of the transport bolts, use the help of professionals. Remember that malfunctions that are not covered by the warranty will have to be fixed at your own expense.

If not removed

If suddenly you did not understand how to remove the shipping bolts on the washing machine, and decided to leave everything as it is, you risk further serious damage to the machine. In addition, bolts can cause unpleasant sounds, vibrations and incorrect execution of specified algorithms. Some owners sin on service specialists, but the matter is precisely in the shipping bolts.

All these troubles are due to springs and dampers washing machine. These are the parts that hold the drum in weight. Their main function is to dampen and soften the vibration. In the case when the drum is tightly fixed with bolts, all vibrations are transferred directly to the external panels. Linen in the tank is arranged randomly, causing even more vibration.

It becomes especially noticeable when spinning is on.

The drum pressed to the panel cannot compensate for the vibration and provokes excessive overloading of all parts of the system. The system of bearings and the engine receive the most damage. Vibrating damages all parts of the device without exception. If the shipping parts are not dismantled in time, each failed node will have to be repaired independently. Removing the bolts will save you many problems.

Do not forget to use the instructions given before starting the instrument for the first time. Work that will take you no more than ten minutes will help avoid serious damage.

/rating_off.png)