Chainsaw sharpening and lubrication

Every tool needs periodic maintenance. If we talk about a chainsaw, then first of all it requires its main working body - a saw chain. Teeth need periodic sharpening. From the correctness of the events depends on the service life of the tool and the quality of the cut. In addition, each chainsaw has a chain lubrication system. Knowledge of its device and the principle of operation is necessary for each owner of this tool.

Content

When need sharpening

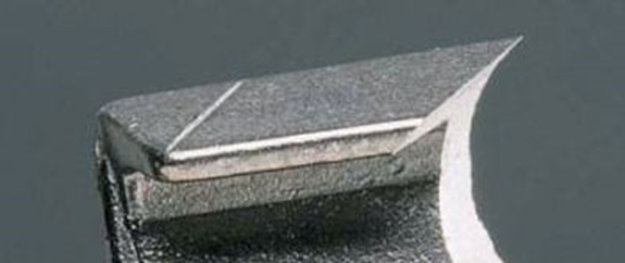

Whatever the company was the unit, the time comes when you need sharpening the chainsaw chain. A dull saw can be recognized by the type of sawdust: if they are mainly composed of fine dust, then it’s time to sharpen the teeth. The sharpening operation can be performed at home, since it is not particularly complex. The photographs below show what a sharpened tooth and a tooth that requires straightening looks like.

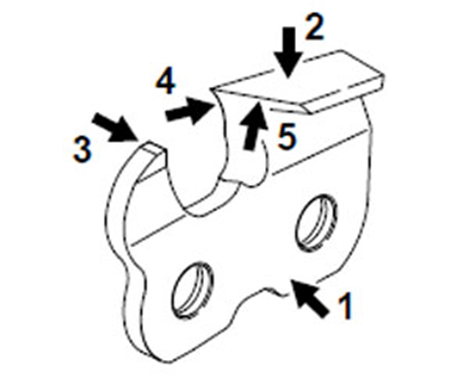

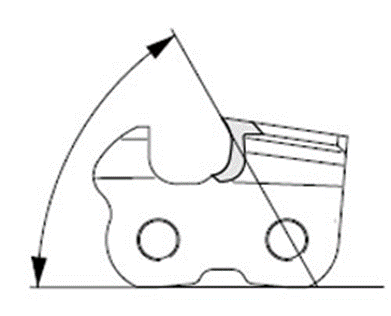

Before starting sharpening the teeth with your own hands, it is recommended to understand the principle on which they work. The following figure shows how sawing occurs.

As can be seen from the figure, the link shape is similar to small plane. Similarly, planing material occurs. Chip thickness is determined by the limiter.

Tooth parameters

The cutting element of the chain (link) has the following structure:

- base;

- tooth blade;

- depth stop;

- end blade;

- upper blade.

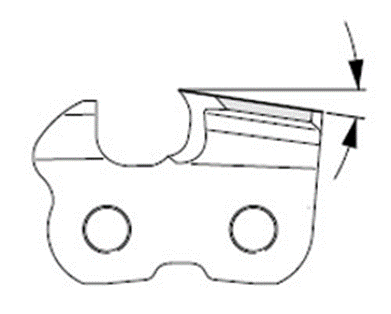

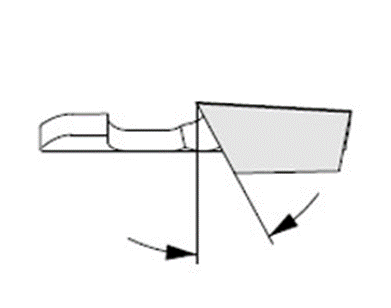

To achieve maximum efficiency when sawing can only sharpening the teeth at the right angle. If you grind off the back part of the back of the tooth, then the back angle of the upper blade will be formed, allowing the edge to easily cut into the material.

Rear scapula It is also ground at an angle to the back so that the vertical blade can cut the fibers of the wood.

The edge of the upper blade should form relative to the bottom of the link. front corner 60-85°.

The inclination of the upper blade in various types of saws can have an angle of 50-60 °.

Sharpening angle measured relative to the guide rail (at right angles).

This angle is usually changed depending on which types of jobs will be held by the chainsaw. If the angle is increased, the non-frozen and soft wood will be cut faster. Reducing the angle of sharpening makes it possible to saw hard woods and heavily frozen wood. In addition to the above, such a measure can eliminate the strong vibration of the instrument and contributes to its smooth running.

The sharpening angle must be at least 25 °, with the exception of longitudinal sawing chains, where a 10 ° angle is considered normal.

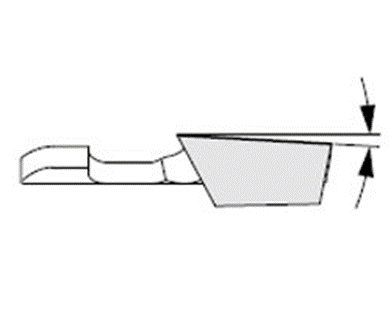

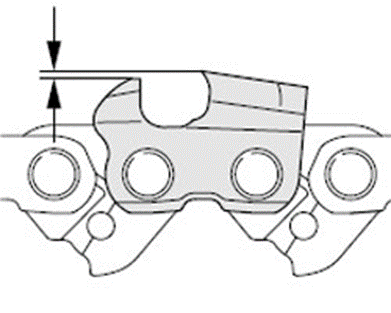

The next figure shows that there is a stop in front of the tooth, which limits the depth of the material capture.

This emphasis, as already mentioned, you can adjust the thickness of the chip and the performance of the unit. The gap between the upper edge and the limiting stop should be 0.5-0.8 mm. If this distance is made larger, the risk of recoil of the chainsaw will increase, the vibration will increase, and the machine will begin to capture more material. With a small gap, the cutting speed decreases.

Chainsaw chains are often sharpened with regular files using special patterns. But you can do it on manual or electric sharpening machines.

File Sharpening

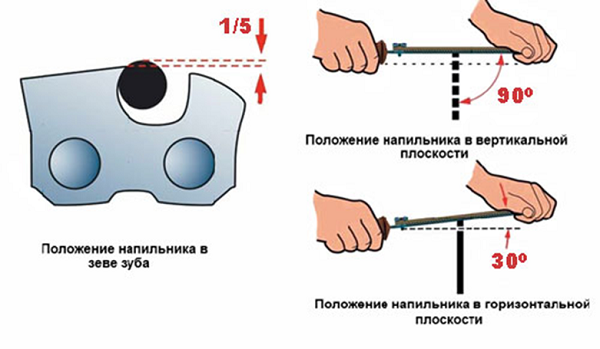

Most often home craftsmen used manual sharpening. So, to properly sharpen the chain, you will need 2 files with different profiles (flat and round). The inner contour of the cutting link has the shape of a circle, therefore it is grinded with a tool with a round section. The depth stop is required to grind down with a flat tool.

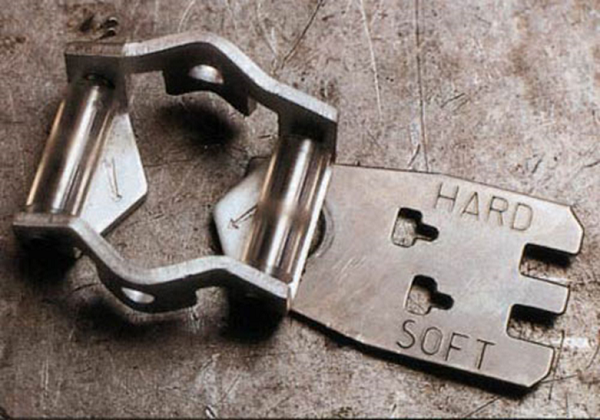

Sharpening a chain of chainsaws "by the eye", maintaining all angles, is very difficult. Significantly simplifies this process. use of templates. One of them is shown in the following photo.

The sharpener should be positioned so that the chain enters the cuts located at the bottom of the template. The file is required to bring under the cutting edge and put on the rollers. Move the sharpening tool in a straight line parallel to the sides of the fixture.

For cutting the limiter to the desired height, the template is superimposed on the link so that the support fits into the hole of the fixture. If you are going to work with soft wood, the emphasis is placed in the hole opposite the word “SOFT”. Conversely, to prepare the saw for processing solid wood, it is necessary to set the delimiter under the word “HARD” on the template.

To grind down the stopper should be a flat file. Movement should be smooth and smooth, away from you.

The next photo shows that the stopper protrudes slightly from the device, and it must be grinded.

You can also purchase branded set for sharpening links, which includes a suitable tool (files) and accessories. Using this kit is as easy as the one discussed above.

Sharpening the chain with the machine

Sharpening machine is used in the following cases:

- cutting links become blunt, for example, when a saw enters the sandy soil or the soil with gravel;

- Chainsaw chains have not been sharpened for a long time, and the working teeth have lost their shape;

- There is no time to sharpen teeth with a file, for example, in production.

Machines can be divided into electric and manual. The latter is more correctly called adaptations, since the physical force of a person is used for grinding. Electric machines have a motor that drives an abrasive wheel.

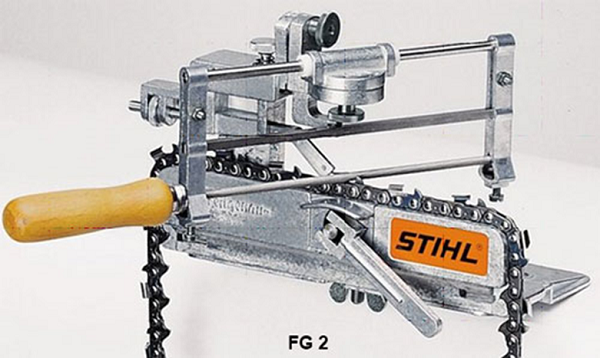

For example, the company Stihl, has released 2 types of manual machines.

- Mobile Sharpener FG 1, which is easily attached to the tire chainsaw.

- Stationary grinding machine FG 2, which can be attached to a workbench.

If you look at the photos of the machines, then you can see that their working part is very similar to the saw, where a file of a round (rectangular) section is fixed as a working tool. To shorten the emphasis in the machine is fixed file with a rectangular section. These machines allow you to edit and sharpen chainsaw chains, adjust the teeth in height (one size).

To sharpen 1 tooth, you need only 2-3 movements.

As already mentioned, there are electric machines. These easy-to-use devices have a flexible system of settings, thanks to which it is possible to install the chain from different angles and bring the grinding wheel as accurately as possible to the surface to be processed, thus achieving the correct sharpening of the tool.

The advantage of electric machine tools is that all grinding work is quick, easy, does not require special knowledge and skills from the operator. Therefore, if you have to constantly sharpen saw chains in large quantities, you should choose a machine with an electric drive.

How the chainsaw chain lubrication system works

In order to supply the lubricant to the links of the saw chain most effectively, it is installed on chainsaws special pump. Its task is to dose lubricating materials to the tire of the unit. The intensity of the oil depends on the number of revolutions of the gasoline or electric drive.

Lubrication system

Details and design of the lubrication system on units from different manufacturers may vary slightly, but the principle of its operation does not change.

The lubrication system consists of the following components.

- Tank for lubricants. As a rule, it is located in the crankcase.

- The filtering element is located inside the tank.

- Oil pipe It is a hose made of oil-resistant rubber.

- The oil pump is the main component of the lubrication system.

- Worm gears. Its main function is the transmission of rotational motion from the engine to the pump.

Tire machine It is also possible to call part of the lubrication system, since it has openings through which lubricant is supplied.

By the way, the chain also takes part in the transportation of lubricant and has some design features for this purpose.

The principle of operation of the lubrication system

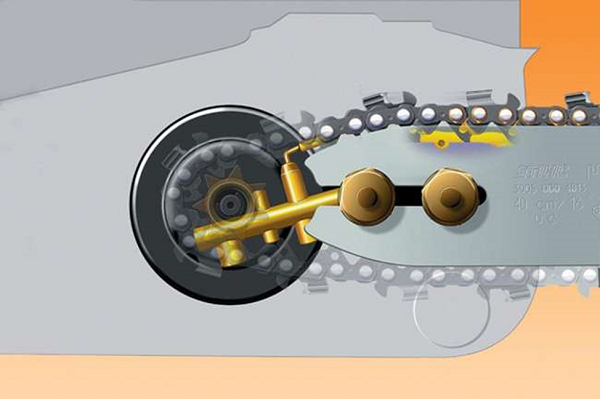

The main node of the system is the pump, and it works according to the following principle. When the engine speed increases, the gear mounted on the main shaft transfers the rotation to the pump shaft via a worm gear. As the pump shaft rotates, the pressure in the line rises. Due to this, the lubricant begins to move in it towards the tire.

The oil channel ends at the point where the tire contacts the crankcase. It is here groovewith which the lubrication channel of the tire is combined.

This groove provides lubricant transportation to the tire, no matter what tension the aggregate chain has. The tire can have any position during operation, but oil will still flow to it through this groove.

Then the lubrication process is included. saw chain. At its links there are either holes or a special groove (depending on the model of the chain). Thanks to such improvements, the lubricant spreads around the entire perimeter of the tire, and lubrication of the chainsaw chain occurs evenly. If the engine speed increases, respectively, the intensity of the oil supply increases.

On some models of units, are installed adjustable pumps grease supply.

In such units, if the need arises, it is possible to increase or decrease the amount of lubricant supplied to the tire.

/rating_off.png)