How to assemble a sandblaster at home

Sandblasting allows high-quality and quickly clean the surface from dirt, matting the glass. The first type of operations is highly in demand in small car repair shops and even private garages. The problem is that the sets of equipment offered on the market are expensive. In this case, for example, in the presence of a home master has enough productive compressor. In this case, you can assemble a sandblaster with your own hands, using, literally, discarded items and parts that you can buy at any household goods store.

Content

Design and working principle of sandblaster

Sand blasting with your own hands can be assembled on the basis of two constructional schemes that differ in the physics of the supply of abrasive material to the output path. However, they will have almost the same list of significant nodes.

- The compressor is the main device for forcing air.

- A receiver that can be made from a gas cylinder.

- Capacity for abrasive material of sufficiently small volume, which is made of freon cylinder or fire extinguisher.

- Pistol, the main tool operator installation.

- Connecting hoses.

Important! To ensure long-term operation and stable parameters of the abrasive mixture, the sandblaster device must necessarily include a dehumidifier. If a reciprocating compressor is used, it is recommended to install an oil filtration system on the air inlet path.

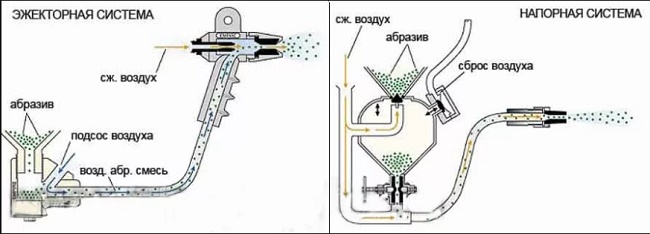

Any homemade sandblasting should form an air-abrasive mixture stream at the outlet. Wherein pressure circuit uses abrasive feed pressure into the outlet, where it mixes with the air flow from the compressor. Household sandblaster ejector type uses the Bernoulli effect to create a vacuum in the abrasive intake path. The latter enters the mixing zone under the action of the atmosphere.

Drawings and self-made sandblasting scheme, on which the apparatus can be assembled at home, are very diverse. The reason is that craftsmen use what they have at hand for their products. Therefore, it is reasonable to consider the general principles on which homemade sandblasting equipment is built.

From which you can collect sand blasting

To understand how easy it is to make a sandblasting with your own hands, it suffices to dwell on the features of the work of each assembly node. In this case, the selection of available parts or finished products becomes obvious.

- Mixing unit. Here from two hoses sand for sandblasting, compressed air from the compressor comes. At the exit - ready air-abrasive mixture. At the same time, there are no requirements, for example, the volume of the mixing chamber, to the node. On this basis, for its manufacture, you can use an ordinary sanitary tee.

- Control devices. A normal manual sandblaster should be able to adjust the air flow.and the intensity of the abrasive material. However, there are no requirements for the control device. At home, this role is well performed by water ball valves made of steel.

- Connection points. To connect hoses to a portable sandblaster, conventional fittings are installed. They can be equipped with hose clamps for a secure fit. All these components are easy to buy in stores.

- Receiver. This part of the design is needed to facilitate the operation of the compressor and stabilize the pressure. The receiver is sure to be needed if you want to get a powerful sandblasting with your own hands. It is possible to manufacture this device from a powder-type fire extinguisher with a large container capacity. Another option is to make the receiver out of a gas cylinder.

- Abrasive chamber. Components for its manufacture may vary depending on the type of installation being created. For example, a mini sanding apparatus of an ejector type is assembled with a plastic bottle for abrasive. Pressure installation will require a sturdy container made of a fire extinguisher or freon balloon.

Important! The connection scheme of the dehumidification and oil trapping devices depends on the specific product purchased for this purpose.However, the majority of models on the market will need to make only a tap from a sanitary tee, on which hose fittings are mounted.

The algorithm for making sandblasting from a gas cylinder or a fire extinguisher

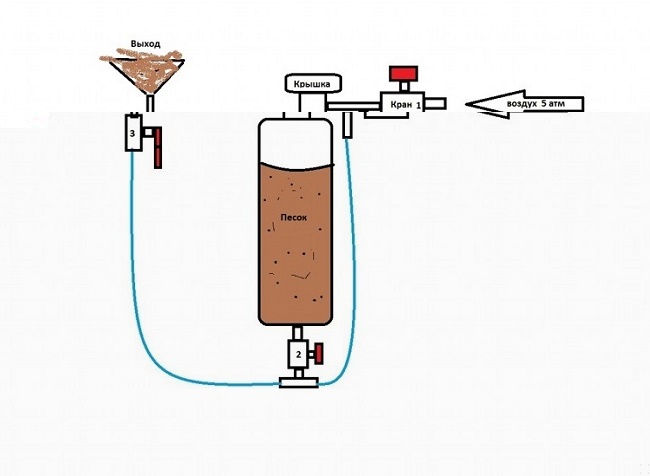

The most simple sandblasting design that you can do yourself is a pressure type installation.. For its manufacture will need (the principles of selection and purpose of the components described above):

- ball valves, 2 pcs;

- freon container, gas or fire extinguisher;

- a piece of pipe to create a funnel of abrasive in the chamber;

- tees, 2 pieces;

- hoses with internal diameters of 10 and 14 mm for the release of abrasive and the air supply from the compressor, respectively;

- fittings and hose clamps;

- plumbing fum-tape to connect the structural elements.

Sandblasting occurs according to the following algorithm.

- The camera is being prepared. To do this, gas is expelled from a fire extinguisher or powder is poured out; the contents are removed from any cylinders under pressure.

- In the balloon make holes. From above - for falling asleep abrasive (corresponding to the diameter of the selected tube), from below - for welding the tap.

- The crane for adjustment of supply of an abrasive can be tightly welded a cylinder. Another option is to pre-install the adapter, on which the regulator is screwed.

- After the crane, using a fum-tape, a tee is installed, a mixing unit.

- A valve is mounted on the cylinder valve, and a tee is installed behind it.

The assembly of the basic structure is completed by welding the wheels or carrying handles. Do not interfere and support legsso that sandblasting is not only mobile, but also sustainable.

Further, the connections and the formation of supply and output paths of the finished working mixture are carried out:

- on the cylinder valve, lower tee - fittings are installed;

- a hose with a diameter of 14 mm air supply is located between the valve tee and the corresponding mixing unit at the bottom of the cylinder;

- a compressor is connected to the remaining supply of the valve tee with a fitting;

- to the free discharge of the lower tee fix the supply hose of the working mixture.

On this creation of the device can be considered finished.

What to do the nozzle and gun

Homemade gun for sandblasting is also not difficult. It can be made using nozzle for ball water valvemounted on the end of the air-abrasive feed hose. This output element is a clamping nut fixing the nozzle for abrasive ejection.

The last element of the structure - the nozzle - can be made of metal, turning the part on a lathe. However more sensible make a nozzle out of a spark plug. To do this, the old part is cut by a grinder, separating the durable ceramic pillar from the metal elements of the structure and forming a suitable length.

Important! The process of separating the desired part of the candle is the inevitable formation of a huge amount of dust and an unpleasant smell. Therefore, if there are no skills in working with a grinder and a workshop, it is recommended to buy a ceramic nozzle in a store.

It should be noted: homemade designs often show better results than a finished sandblasting pistol, many models of which are presented at retail. Therefore, it is reasonable to spend time creating your own solution, which does not require significant financial investments.

Alternative manufacturing methods

Many options for homemade sandblasting due to the needs of the owners and the various available materials. You can make your own efficient installation using products intended for other works. For example, to assemble a dust-free sandblaster with their own hands will help the unit for high-pressure washing. Below are some working and effective options for homemade installations.

From high pressure washer

Sandblasting can be collected from Kärcher. This car wash creates a high pressure of water at a low flow rate. To get an efficient, dust-free installation, you just need to assemble a special nozzle on the outlet tube. Would need:

- self-made or purchased in-store ceramic nozzle;

- reinforced hose;

- mixing unit, suitable tee with a suitable diameter;

- feed adjustment unit, dispenser with cylindrical type;

- abrasive intake tube, equipped with an air supply path to a closed container with sand or other material.

Water sandblasting from Kärcher working on the ejector circuit. Water under high pressure, passing through the mixing unit at high speed, creates a vacuum in the path of the abrasive. The sand enters and is ejected with high-pressure fluid.

Water sandblasting of this design has some features.

- The flow rate is high with low water consumption.. This allows the installation to be used for glass, matting or other processing.

- For stable feeding, an abrasive of uniform dispersion and a small fraction should be used. In living conditions, fine, sifted river sand.

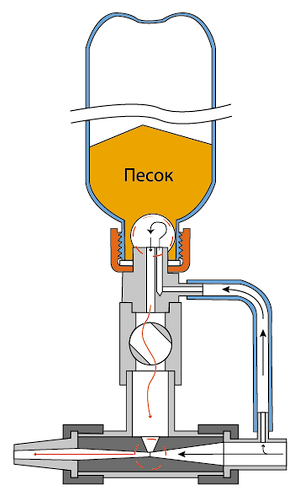

From the purge gun

Small and efficient - this is how you can describe sand blasting from a blow gun. This device will allow with sufficiently high efficiency to carry out, for example, body work. However, the performance depends entirely on the compressor used. To assemble the device will need:

- finished pneumatic blow gun;

- sanitary tee;

- ball valve to adjust the flow of abrasive;

- clamping nut exit nozzle.

The design is not complicated. How to collect it - can be seen in the following photo.

As capacity for an abrasive it can be used as an easy cylinder from a powder fire extinguisher, and plastic bottle.

Using a spray gun

You can create a self-made sand blasting from the spray gun. For this you will need:

- mixing valve from a conventional spray gun;

- the handle with the air supply mechanism of the spray gun;

- bottle for abrasive mixture:

- tee;

- ball valve regulator.

The scheme of the finished device is as follows:

To build the structure you will need:

- pierce the spray gun to use the nozzle of the desired size;

- attach a mixing tee to the pistol;

- Install and secure the supply and circulation hoses.

Important! Starting the supply of sand or other abrasive from the tank is carried out by simply pressing the trigger. The volume of the bottle is enough to handle small parts or surfaces for 20-30 minutes.

As a conclusion

So that the self-made sandblasting does not become a problem and does not spoil the health of the owner, do not neglect the simple safety regulations. It is recommended to immediately remove dust from the treatment area. A device for solving this problem can be made from a vacuum cleaner.However, to achieve the maximum level of protection, it is imperative to work in a respirator, use an untight sealed chamber for cleaning and grinding small parts.

The most popular sandblaster in 2018

Device sanding AE & T T06505 19 of l.

Sand blasting machine 17 l GARWIN 8866101

N33235 Sandblasting camera 90l. AE & T T06301 table

JTC-5324 Sand blasting machine, 1/2 ″ hose, max. pressure 250PSI, volume 38l.

Sandblasting gun Fubag Sbg142 / 3

/rating_off.png)