Homemade grinder from the grinder

Performing repairs or making furniture, a specialist just needs to have such a device as a grinder, which allows you to grind various materials. And when performing welding, such a mechanism is simply irreplaceable. Purchase this device in your own workshop - the desire of any master. However, an industrial grinding machine is quite expensive. And having it without doing it professionally is expensive for the family budget. That is why there is a desire to make it your own hands from the mechanisms at hand. The Bulgarian is best suited for this purpose: it can easily be transformed into a necessary power tool.

Content

Ready nozzle for angle grinders

The simplest thing is to purchase a ready-made grinding device and mount it on the angle grinder.The photo shows that the installation of the mechanism is not particularly difficult. It is enough to attach the bracket with the rollers to the angle grinder, after dismantling the protective cover. The drive wheel is fixed on the shaft of the LBM. Sanding pads are put on the rollers, and the grinding machine is ready for use.

For convenience, you can secure the device to the table with clamps.

However, such a device is not always possible to buy in the store, and the cost of such a gadget is significant.

To reduce costs, but at the same time limit the use of the grinder allows the prefix consisting of rods with two rollers. The device allows for a few minutes to make a grinder from the grinder. The fixture has a standard mount, suitable for mounting on an angle grinder.

The design of such a mechanism is intended for stripping welds. To polish wooden products with such a gadget is quite difficult. However, if it is rigidly fixed on the table, it can be successfully used as a sharpening machine for straightening cutting tools or sharpening knives, axes, etc.

Such a device is also manufactured by industry, but it is extremely rare to find it for sale.

Self-made mechanisms for angle grinders

In order not to look for ready-made nozzles, you can try to make them yourself. There are various options for the manufacture of such devices, which will be discussed below.

Plywood

First of all, consider the option of how to make an unpretentious grinder from the grinder with your own hands. The simplest version of the grinder is obtained from the angle grinder, two rollers, tensioning mechanism and the base of plywood.

For the manufacture will need a thick plywood - it is an affordable and inexpensive material.

The hardest part of this design is roller making. It is good if there is a milling machine or a manual mill in the home workshop. For this, a suitable billet is machined from plywood with a mill, machined on a grinding machine, bearings are pressed in.

A base is cut from the same plywood, in which a hole for the grinder is cut. Mark up space for the rollers, then fix the angle grinder and mount the wheels. Beforehand it is necessary to process the ground wheels with varnish.After that, the entire system is assembled, and the grinder from the grinder is ready for operation. The design of the device is clear from the presented photo.

Sheet metal

If there is a welding machine in the workshop, and the familiar turner will drain out the necessary rollers, then a polisher can be made from metal residues.

For this well-suited remnants of thick sheet metal, which will go to the manufacture of the base.

Such a device will not be worse than the factory. In the manufacture will have to spend quite a lot of time, but it is worth it. Before you get to work, you need to develop working drawings or download them from the Internet. By assembling the mechanism not according to the drawings, the desired result may not be achieved, or the resulting device may be a source of increased danger.

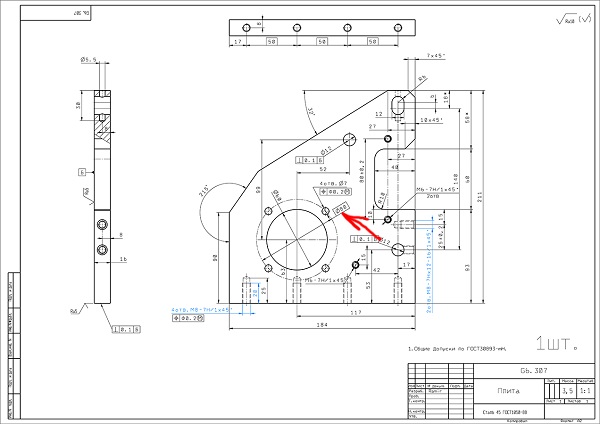

First you need to make accurate bed marking. As an example, we use the following device drawing:

The arrow indicates the diameter that needs to be specified depending on the angle grinder used in this design.

On the milling and drilling machines on the markup drill holes. Then you need to prepare tension baras presented in the photo.

To grind the rollers, and only then proceed to the assembly mechanism. The result was a universal console, as a power unit of which you can use not only the grinder, but also another suitable electric motor. The finished view is shown in the photo below.

From the remnants of the pipe

Having the skills of a welder, you can easily convert the grinder available in the home workshop into a grinding machine. Enough for that

- weld trim angle or square tube in the shape of a letter;

- fix suitable rollers on the ends;

- fasten the drive shaft to the shaft of the angle grinder;

- mount the sanding cloth and the device is ready for operation.

Such a grinder can perform various operations:

- clean the irregularities of the metal after welding;

- perform a full part grinding;

- handle wood products;

- make final, finishing treatment before coating the part with varnish;

- handle roughness of concrete walls.

In order to clean or grind various surfaces, you should select a sanding cloth intended for the material being processed.

Safety

When working with a homemade grinder, you should not neglect safety precautions and personal protective equipment. Persons under the age of 18 should not be allowed to work. When using the device it is necessary to use protective glasses and earplugs to protect the organs of sight and hearing from the harmful effects of external factors. We should not forget about the mask that protects the respiratory system from dust.

In the video below you can study in detail how and from what to make a device for grinding. It also gives all the basic dimensions of the parts of the mechanism.

/rating_off.png)