Grinding by grinder of various materials

Today, the Bulgarian is a universal device with which you can perform all kinds of material processing operations. LBM is used for leveling walls or floors, it can be used to clean or polish metal products. It is indispensable when performing repair work on the car. It is almost impossible to replace it where it is necessary to cut, grind or grind parts made from any material. This article will discuss the use of angle grinders for grinding and polishing wood, metal, concrete and bricks.

Content

Wood processing

For those engaged in the construction of wooden houses, repair or manufacture of wooden furniture, it is important to be able to properly handle wooden products. First of all, are determined with the necessary tool. The most common and affordable is the angle grinder (angle grinder) or, as it is also called, Bulgarian. This tool is available in every home. With it, you can do almost all the work of wood processing: sanding logs, level, grind and polish.

Nozzles on the grinder for wood

First of all, you need to know what nozzles are used for this or that operation.

- To perform a rough preparation of logs during the construction of the log use disc - plane. Working with such a nozzle, the tool should be held with two hands. Sometimes workers remove the cover, but then it is necessary to protect the face from flying chips.

- Peeling disc designed to remove bark from logs. If necessary, they can saw off lumber. In this case, the disadvantage is a wide cut and a large number of sawdust.

- Finishing is used when grinding a log house. In this case, use abrasive discs.

- Korshchetki used when it is necessary to level the surface.

- End discs are used when machining ends, corners, or oblique cuts.

- If grinders of wood are grinded, scraped floors, finished ends and edges, prepared the surface before painting, apply petal nozzles and grinding wheels.

- To grind boards grinder, apply fine-skinned circles, felt or other material.

These are the main, but not all nozzles used for the angle grinder. In order to grind a grinder tree, you need to know the basic techniques. Stripping of the frame is done using end nozzles. The fixture should be held at a slight angle. With such a nozzle, it is easy to clean not only the corners and joints, but you can and effectively clean the logs. In the same way produce grinding timber.

Use of angle grinders for artificial aging of wood

Wood processing, which makes it artificially aged, is very popular now. This technique is called brushing

The work is performed by an angle grinder using a special set of nozzles.

When performing such an operation, the device should be moved along the fibers.

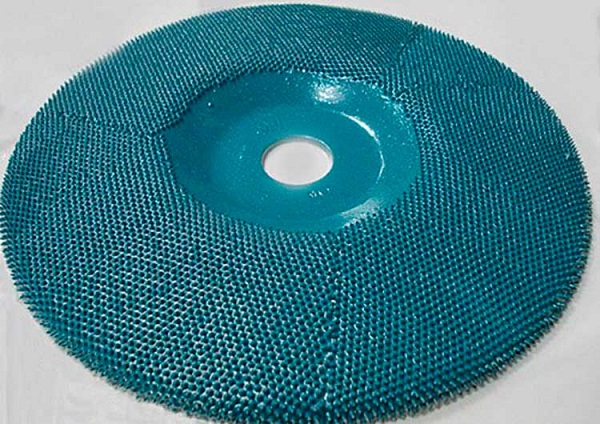

First used steel pile cap. It makes selective removal of fibers, making rough processing of a bar. Before dyeing, blanks are finished polished using devices with a copper or sisal bristle. Sometimes used universal abrasive - polymer brush.

Sanding a wooden floor

When carrying out a major overhaul of a house, it is often necessary to sand a wooden floor. First of all, it is necessary to remove all the projections using the appropriate fixtures. And only after that they produce wood finishing, applying grinding wheels with the required grain.

To properly polish wooden products, you should know that there are many methods by which you can bring the workpiece to the desired state. Each of these methods has its advantages and disadvantages. In order to get work done, you need to have some experience, and also not to forget about the means of individual protection.

The use of grinders when grinding concrete

With the help of LBM it is possible to make cleaning not only wooden elements of the house.It can be used when you need to level concrete products with your own hands. Grinding of concrete is most often performed by a grinder.

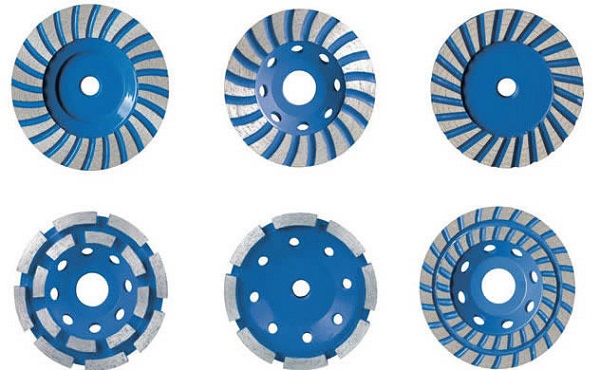

Before starting work, you should allow the floor to be flooded for about two weeks: during this time, the concrete will pick up the necessary strength. Before sanding a concrete floor, its surface should be coated with a special compound, which, entering into a chemical reaction with calcium hydroxide, forms a mineral - binder. It is able to close the pores in the concrete, which will give greater strength to the material and resistance to moisture. Grinding the floor is done with diamond cups, specially designed for grinding concrete.

If you use cups with a grain size of 400 or higher, you can get an ideal mirror surface.

Scraping and polishing metal angle grinder

Often grinding is necessary in the manufacture of metal products by welding. Before painting on the finished product it is necessary to clean the welds, for which ordinary cutting discs.

Holding the angle grinder at an angle, remove all irregularities, thus leveling the surface.After that, the disk is changed to a grinding wheel and bring the surface to the desired state, changing the grain of the sanding cloth, if necessary.

Thus, it is possible not only to grind the metal with a grinder, but to polish it.

Despite the apparent ease of operation, you should not neglect the safety regulations. It is necessary to work only with the use of personal protective equipment.

Cutting and leveling brick cuts

Grinder grinder not only wood, metal or concrete. This versatile tool is the best for cutting or grinding bricks. As with the other types of work, in this case, too, has its own subtleties.

First of all, it is necessary to choose the right cutting element. For this fits abrasive discwhich copes well with the task, and the cost of such a circle is not great. However, with all its advantages, there are significant drawbacks.

- During work, he experiences intense wear, resulting in disc diameter greatly reduced. If you cut bricks of small thickness, then this drawback is not so noticeable.But when cutting material with a large thickness, it will not be possible to achieve an even cut, since the workpiece will have to be turned over and cut from different sides.

- The second disadvantage is quick failure. To work will require a large number of such circles.

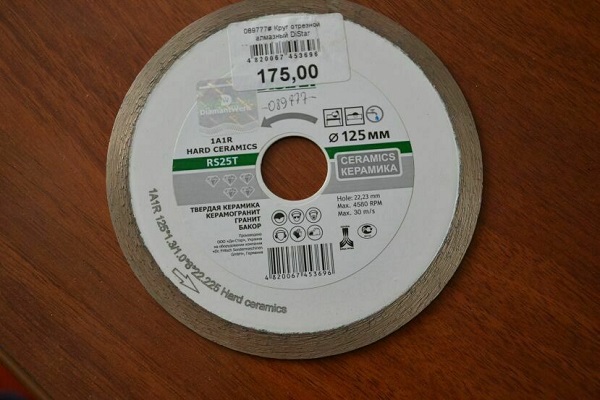

The diamond circle, divided into segments, is devoid of these shortcomings: when performing operations with a stone, it does not wear out, which means that the diameter remains constant. Diamond coating is abrasion resistant, which affects its durability.

Processing brick grinder - not such a difficult operation. The most important thing is to correctly mark up, taking into account the thickness of the cut. However, it is not always possible to obtain a smooth cut surface. In this case, the surface is smoothed with grinding wheels.

The angle grinder is a high-risk hand tool. Therefore, when working should be observed safety precautions:

- do not allow strangers to perform operations;

- use dustproof clothing at all times;

- use personal protective equipment for the eyes, respiratory system and hearing.

These requirements are valid when working with wood, metal, concrete, brick.

/rating_off.png)