Choosing a spray gun for home

Painting works are a rather laborious task, especially if you need to apply a layer of paint, varnish or a protective coating on an uneven surface or a large surface area. Considerably simplifies the task of the airbrush (paint sprayer), with the help of which the application of various coatings occurs quickly, efficiently and with minimal physical costs.

Content

Purpose of the spray gun

The device is designed to create an aerosol, that is, suspended in the air small particles of any substance, such as paint, varnish, solution for whitewashing, antiseptic, etc. And more precisely, the spray gun is needed for the directional transfer of small particles of a substance to any surface in an even layer, without the formation of bubbles and drips.

The device for spraying paint and other substances in its various modifications is used in the following areas.

- For painting metal structuressince this is a rather laborious process, especially if the work is carried out at a height. Thanks to the use of the spray gun, all hard-to-reach places are easily painted.

- For whitewash lime premises in order to destroy fungi and various small insects. Very often, the treatment of large areas of walls and ceilings with lime is carried out in livestock buildings. In such cases, lime is used for conventional construction spray gun, intended for whitewashing the walls with chalk.

- For painting walls and ceilings in residential and non-residential premises. For the ceiling, a special device with an elongated body is used, which allows the coating to be applied without using a stepladder.

- For soil. The primer is applied to the surface before applying the main decorative coating. Also spray guns are widely used for oil paints, for water dispersion paints and for water-based paints.

- For antiseptic. With the help of a sprayer, you can apply various antiseptics to fight bacteria, fungi and insects. Therefore, for example, before starting the construction of a wooden house, in order to get rid of tree beetles or fungi in logs and other wooden elements, various protective compounds and impregnations are applied with a spray gun.

- For antigravia. Many motorists are concerned about the corrosion of metal parts of the car and try to put on time, for example, on the bottom of the car anti-corrosion compounds. For this purpose, the best possible spray gun.

- For powder coating. Devices working with powder dyes are often used in car services for painting car bodies.

- For varnish on wood. The composition is convenient to apply in the manufacture of furniture and other wood products. Also spray gun for wood is used when applying the stain on wooden surfaces and for painting furniture.

- For small parts. Since the painting of small parts takes a lot of time, the spray gun will simplify the task a lot and allow you to apply the coating in just a few seconds.

Types of spray guns

The family of paint-sprayers can be divided into types, and their device determines the principle of applying paintwork and protective coatings. The following types of spray guns are on the market for painting equipment:

- electrical;

- pneumatic;

- rechargeable;

- airless;

- high and low pressure;

- with upper and lower cistern.

We will understand what is the difference between them.

Electric spray guns

An electric paint sprayer is a device without a compressor, but in which a piston pump is built in, driven by an electromagnet with an oscillating bar. Also some paint sprayers are with built-in compressorcreating a stream of air due to the rotation of the turbine by an electric motor.

Turbine Spray Gun as well as the piston one, it works from the 220 V network. And since for this type of devices it is not required to specifically purchase a compressor with a receiver, they are often chosen for domestic use.

In addition, there are electric paint sprayers with remote compressor. The latter can be large in size and is designed to be placed on the floor. Basically, these are devices for professional use.

Household appliances have compact dimensions, and during operation they are suspended on the shoulder with the help of a strap that is present in the set to the devices.

Pneumatic pulverizers

Pneumatic spray gun works only from compressed air.

For the production of the latter a compressor is required. To stabilize the air flow and maintain air pressure at the same level, a receiver is installed between the compressor and the spray gun.

As a rule, the pneumatic type of the device is a professional spray gun, thanks to which they achieve the perfect quality of paint application. The tool has a standard nozzle diameter of 1.4 mm. If you install a nozzle with a diameter of 1.8 mm or more, the device will turn into a primer spray gun.

Among the professional models can be seen and electronic spray gunthat is, with a digital pressure gauge.The presence of an electronic gauge allows you to fine-tune the device, which is very important if you want to achieve the same intensity of spraying of the dye.

Also to pneumatic devices can be attributed automatic paint sprayer, which is mainly used in production as part of automatic plants for applying various decorative and protective coatings.

Battery Spray Guns

Kraskoraspyliteli, working on the battery, are analogues of conventional electrical appliances. The only advantage of the battery-powered spray guns is mobility, which makes it possible to work in places where there is no electrical network.

But it should be borne in mind that this manual spray gun will not be able to work for a long time due to battery discharge. On average, such a device works for 20-30 minutes, after which it is necessary to replace the battery. Therefore, the battery spray gun is usually used to perform works of small volumes.

Airless Paint Sprayer

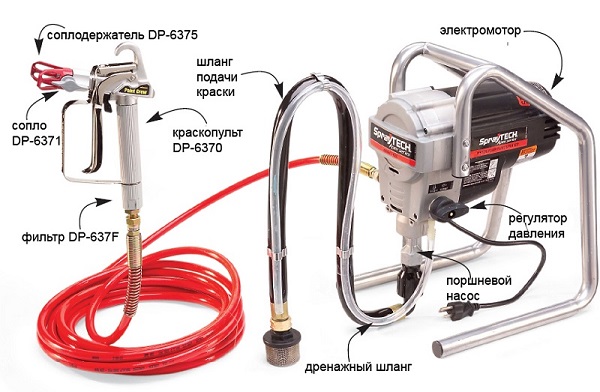

As can be seen from the name of the device, the paint is sprayed without the use of compressed air. In airless spray guns (plunger) paint is fed to the nozzle under high pressure. To ensure the flow of paint into the plunger spray gun, a piston pump driven by an electric motor is used.

To determine which spray gun is better - air or airless, you need to understand for what purpose the devices will be used.

Air paint transfer method implies the formation of a soft plume of coloring matter, which is applied to the surface to be treated with a thin layer. Due to this, high quality coating is achieved, including in hard-to-reach or raised places. But due to the low viscosity of the paintwork material and low air pressure, not all small particles of the substance reach the painted surface. A considerable part of them remains in the air and surrounds the painter.

Airless Spray Gun, as mentioned above, works at high pressure, which makes it possible to use a more viscous dye. Consequently, its particles have a greater mass than with air spraying, and all reach the surface being painted, without turbulence. In this case, the paint is consumed more economically. Although airless method and you can achieve high quality paintwork, but for painting the relief details of this type of spray is not suitable. This is explained by the greater density of paint, which will be applied unevenly on a product of complex design and form “sagging”.

High and low pressure paint sprayers

High pressure units (up to 56 atmospheres) are intended for spraying viscous paint and varnish compositions. In addition, these spray guns can be applied mastic on the basis of bitumen, primers and compositions with anti-corrosion properties.

Spray gun low pressure is the most popular machine among the masters involved in painting cars. Kraskoraspylitel can work with a pressure in system in 2 atm. and saves up to 30% of paint and varnish compositions.

Important! For operation of the device requires a compressor with a receiver and, preferably, with a gearbox that allows you to adjust the air pressure at the entrance to the gun.

Devices with upper and lower tank

If the spray gun is installed tank at the top, then the flow of paint into the tool is due to the force of attraction. Spray gun with a top tank is used to apply various coatings on small areas. Devices with the upper tank are more economical, because the paint is consumed completely, which is not the case with the tool, where the spray gun tank is installed at the bottom.

At lower location of the tank Liquid is pumped into the device due to the vacuum created by the compressed air flow. Spray gun with a lower tank can be used for coating large areas, since the capacity of such a device is much higher than the volume of the upper tank.

Powder machines

Powder Spray Gun is a device that works. with dry dyes. The main element of the device is an electrostatic converter.

But still, the operation of the device is impossible without compressed air.The latter, passing through the spray gun, transfers the powder towards the electrostatic transducer, where it is ionized. Further, the ionized powder particles are blown through a nozzle onto a painted surface having an opposite charge, and adhere to it.

Important! Powder paint sprayers allow you to apply a uniform layer of paint, not only on smooth surfaces, but also on the relief.

There are also powder sprayers that do not use electricity to ionize powder particles. Such devices are called tribostatic.

The powder dye particles in the gun are ionized due to friction against the inner walls of the tribostatic barrel and collisions between themselves, after which they are blown onto the surface to be treated with air flow.

Type of gun

All types of paint sprayers also differ in the type of gun.

- HP (high pressure). The design of the tool allows you to apply the coating at high speed. For normal operation of the device requires a pressure in the system of 5-6 bar. In this case, the loss of paint when the gun is in operation does not exceed 50%. Accordingly, HP class tools are inexpensive, easy to use, but they cannot boast of good coating quality.

- The tool is able to work at low pressure, but with high air flow. At the same time about 65% of the composition is transferred to the surface. Compressed air is supplied to the apparatus under great pressure, therefore, for the operation of the tool, a compressor with high productivity is needed. The quality of the HVLP grade gun coating can be called pretty good due to the stability of the torch. Also, the speed of the device remains high. Therefore, this type of tool is considered the most effective.

- Pistols have a minimum loss of paint, about 20%, due to the work at low pressure and low air consumption. Devices allow you to achieve high quality painting and do not require good compressor performance (200 l / min is enough). The only drawback of LVLP pistols is the high cost.

Choosing a spray gun for domestic and professional use

To choose the right spray gun for home or professional use, it is necessary to take into account such instrument characteristics as:

- spray gun class (type);

- tank material and its location;

- dimensions and weight;

- nozzle size;

- power (for electrical appliances).

Paint Sprayer Class

Since the paint sprayer of the class HVLP can work with low pressure and provide an acceptable quality of paint, it is better to buy such a model of gun for the home. Of course, for the professional sphere you will need to purchase an industrial tool of class LVLP.

Tank material and location

Tank for paint and other compositions are made either from plastic or from metal. Plastic Tanks convenient because they are translucent and allow you to visually determine the level of paintwork material embedded in it. In favor metal containers spray guns say that they can be washed with aggressive solvents that can damage the plastic canister.

Also, when choosing a spray gun, you should consider tank locationOn which it depends on whether the painter can perform this or that work. The upper arrangement of the container is considered universal and allows the application of compositions both on the ceiling and on the walls.In some devices, the upper tank can be connected using a flexible hose that allows you to set the container in the desired position.

At the bottom tank fixing the device will work only in horizontal position. If the tool is raised vertically, for example, to whitewash the ceiling, the solution will no longer flow into the tool. The only thing that is convenient is the lower tank - this is an increased volume, allowing you to fill it with a large amount of paint or other composition.

Dimensions and weight

To a greater extent, these parameters include to electric paint sprayers. The larger the size of the compressor or pump, the higher the performance of the device for spraying compositions. Therefore, professional craftsmen prefer to use electric spray guns with an external compressor (outdoor).

Household electric paint sprayers have a small size, a pump built into the pistol and suitable for small paint work around the house. In addition, this mini tool can be produced with small external compressor. Due to its low weight, it can be carried on the shoulder while working with a spray gun.

Nozzle size

The nozzle from the spray gun, or rather the diameter of its outlet (nozzle), directly wags on the size of a drop of paint material that is sprayed. Choosing a paint sprayer, you need to know what types of work will be carried out with it. For spraying various materials it is required to select the appropriate nozzle diameter:

- for spraying water-based paints, as well as applying the base and varnish, a nozzle diameter of 1.2-1.6 mm is required;

- acrylic-based paints and varnishes require a nozzle with a diameter of 1.4-1.7 mm;

- devices with a nozzle with a diameter of 1.5-2.2 mm work well with primers;

- for thick formulations, for example, liquid putties, a nozzle diameter within 2.5-3 mm is required.

Therefore, it is recommended to buy a tool that has a set of several interchangeable heads, allowing it to become universal.

Power of electric spray guns

Devices having power up to 500 watts, are considered domestic, have low cost and are more suitable for beginning painters. They do not work well with thick formulations, apply dye unevenly, which affects the quality of the coating.

For professional use should choose devices more than 500 watts which will be able to cope with the compositions of any viscosity and evenly spray them on the treated surface.

Useful additions

Since the spray guns are used to perform a large number of different types of work, in some cases additional elements are connected to them to make more efficient use of the devices.

- Paint pot. It is a container with a hermetically closed lid. Also, the tank has fittings for connecting the hose from the compressor and a hose for supplying paint to the gun. Thanks to the paint tank, it is possible to apply coatings on the surface of a large area.

- Dehumidifier. It must be installed between the compressor and the spray gun, if the quality of the paintwork high demands.

This need is explained by the fact that there is a certain amount of moisture in the atmospheric air. When compressed air compressor, moisture begins to condense in the receiver and in the air hose. Further, the moisture gets into the gun and mixed with paint material. If the composition has a water base, then the quality of the coating will not deteriorate. When using other dyes and varnishes, the presence of moisture in the supplied air will cause their detachment or the formation of bubbles after application. - Air filter. Designed for fine cleaning of air entering the gun from small solid particles.

Also, this filter is able to work as a dehumidifier.

/rating_off.png)