Alteration: motor for trimmer based boat

Any fisherman who has an inflatable boat available sooner or later begins to think about purchasing a motor for her. But, having learned the price of ready-made solutions, many begin to look for alternative engine options for their craft. Fortunately, craftsmen have already figured out how to remake a lawnmower, screwdriver or benzokosu in a boat motor. But the best option for these purposes is a gasoline trimmer, which has in its design all the necessary mechanisms and elements.

Content

Advantages of using a trimmer

First of all, it is worth considering the main advantages of using a trimmer for the manufacture of outboard motor:

- trimmer cost is significantly lower than the cost of the finished motor for the boat;

- very economical fuel consumption;

- reliability during operation;

- small weight that is very important when using the trimmer on rubber boats;

- built-in translucent fuel tank, through the walls of which the level of gasoline is clearly visible;

- quite tight design;

- a rigid shaft is installed in the rod;

- to control the unit there are ready-made elements (starter and gas).

All these qualities of the device put it in the first place, if we take into account other options for alterations. So, to make a trimmer (required power from 0.7 kW) turned into a full-fledged outboard motor, you need to purchase special set of nozzles or make them yourself.

Ready set of nozzles

At the moment there are ready nozzles on the benzokosu, which allow with minimal effort to convert your mower into a motor for a boat.

The prefix already has a ready-made solution for attaching it to the trimmer's gasoline engine.

Also attached to the rod control handle with silencer button. The gas handle is made in the likeness of a bicycle (meaning a bicycle with a gearshift) and has a ratchet fixing the selected position.

This kit even includes special clampdesigned to secure the entire structure on the boat (on the transom of the vessel).

The trim cap is easy to assemble as its construction is very simple. It only remains:

- connect the gas cable to the engine;

- connect the silencer wires and the unit is ready for operation.

If you read the reviews on the Internet about this device, then, in general, they are positive.

The cost of this nozzle for trimmer varies around 5,000 rubles.

Motor for a boat do it yourself

The easiest way to make a motor for a boat is a trimmer with a straight barbell and a rigid shaft. If your unit has a curved bar, then it will have to be redone.

Reworking a bent shaft

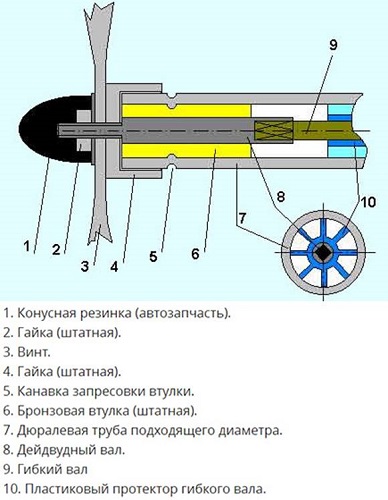

First of all, you need to get a regular nut number 2, shown in the diagram below. It looks like a cylinder 2 cm high with a thread cut inside it.

Important! All unscrewed nuts must be preserved, since non-standard threads (not metric and not inch) are cut in them.

Next, the alteration of the rod is as follows.

- Remove the metal flexible shaft (9) and the tail shaft (8) from the rod by unscrewing the nut (4).

- Since the end of the bent rod does not contain any bearings, and their role is performed by a bronze bushing (6), it is required to cut it.

- After the bronze bushing (6) has been removed, you need to knock out the plastic protector (10). Since the pipe is metal and curved, it will not be possible to align it, you can safely throw it away.

- Pick instead of discarded pipe duralumin, with a similar diameter (internal). It will be better if the diameter is slightly smaller than the diameter of the previously removed sleeve.

- A bronze bushing (6) must be pressed into the pipe. May need to bore a little pipe.

- Press the sleeve along the groove (5) with a hammer. This should be done very carefully, without making great efforts, so as not to deform the sleeve (6).

- The tread (10) is trimmed to the desired diameter and tightly inserted into the bar.

- In the case when the tube you have chosen will have a large outer diameter, and you cannot insert it into the hole in the motor head, you will have to pierce it to the desired size.

- Instead of a flexible shaft, you can take steel bar and connect it to the dead shaft (need help turner).

- The screw is fixed on the shaft with a nut (2).

- The rod with the inner shaft is attached to the motor using adapters made specially in the turning shop. A universal drawing of adapters does not exist, since different trimmers may have their own design features.

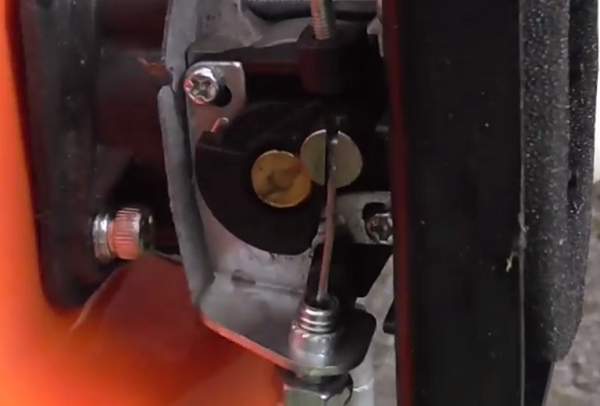

The use of gear from the grinder

Also for independent production of the boat motor on the basis of the trimmer the reducer from the Bulgarian is often used, but with some modifications.

- It is necessary to disassemble the gearbox, and instead of a shaft with a gear wheel, order a new, longer one from the turners (according to the trimmer bar). The end of the shaft is made similarly extracted (short), so that you can use the same bearings and gear.

- It is desirable in the place where the bearing is installed to install the oil seal so that water does not fall into the gearbox.

- The housing of the gearbox is twisted using a sealing gum and sealant.

- It is possible to fill in the gearbox inside the gearbox or to cover the gears with plenty of grease.

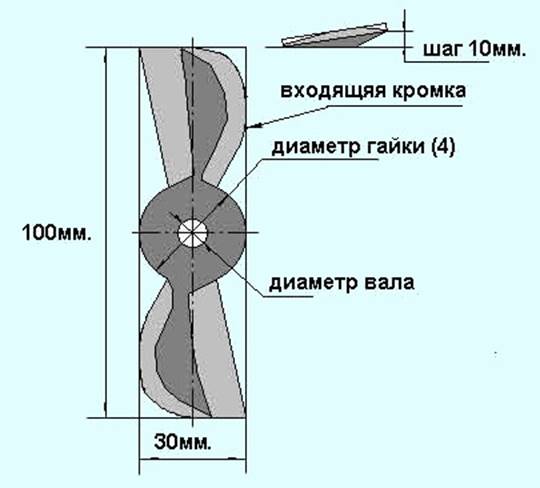

Screw making

To make a screw for the outboard motor, you can use small piece of duralumin 2 mm thick. For the screw, you will need a strip with a width of 30 mm and a length of 100 mm. Make it according to the drawing below.

The screw pitch implies the following: if the propeller is placed on the table, then there should be a distance of 10 mm from its surface to the blade. The angle of inclination of the blades is easily adjusted with the help of pliers, after preliminary annealing of duralumin.

This option is not final, and on the Internet you can find a lot of drawings of screws with two blades, with three blades, as well as different dimensions. In each case, the size of the propeller is selected individually.

/rating_off.png)