Autoclave - Medical Steam Sterilizer

Processing medical instruments and materials to sterilize them is a responsible and serious process, the quality of which determines the health of patients and doctors. The procedure should guarantee the complete destruction of pathogenic microorganisms, because the instruments that have passed the sterilization stage will be re-used in many areas of medicine when examining a patient. For this purpose, a special device was developed - a medical sterilizer, which has many varieties.

Content

Types of sterilization

Key types of devices whose purpose is to sterilize medical instruments operate on the basis of dry hot air, steam and glossper glass.

Sterilization methods:

- By the air.

- Steam (most common).

- Glosperlenovy.

Dry method

The method of disinfection with dry hot air has both its advantages and disadvantages. The advantages of this method include simplicity and efficiency, the process does not require additional costs. During sterilization with a similar method, the instruments are not subjected to humidification, which is an absolute advantage.

Minusesdry sterilization method are the following circumstances:

- Long enough process.

- Dental instruments of small size when heated at temperatures above 160 degrees become less sharp and reliable.

- Lack of international standards governing processing. Since this method is not regulated by anyone, the procedure based on it is spontaneous. Such circumstances may adversely affect the health of doctors and patients due to unscrupulous and poor-quality sterilization of medical items.

The process of air disinfection has not been used for a long time either in Europe or in advanced medical centers in Russia. The only exception is pharmaceuticalswhere ointments and suspensions are sterilized using this method. This method can not be called a competing recently appeared modern.

Steam method

This method is considered one of the most reliable and fast. Its advantages are:

- Rapid destruction of pathogenic single-celled organisms at low sterilization temperatures.

- The ability to treat medical waste with hot steam under high pressure.

- The ability to handle medical instruments, a variety of tips, rubber devices that can not be subjected to high temperatures.

Glosperlen method

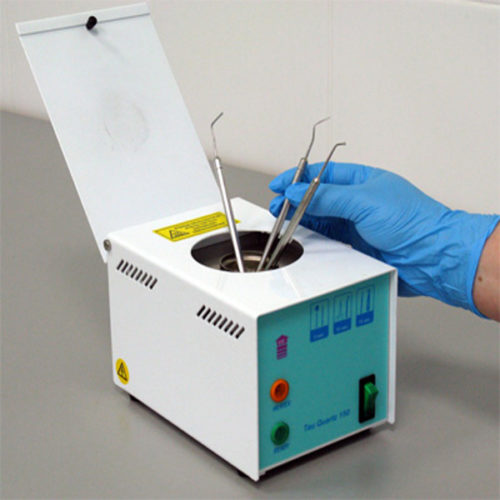

Due to the improvement of technical equipment of medical institutions, it became possible to use new methods of sterilization. One of these is glossper steam bench sterilizer. The principle of its operation is based on the processing of instruments (only metal ones) by placing them in a flask with heated quartz balls (up to 330 degrees).

The undoubted advantage of such sterilization is the short time of the procedure itself: it will take less than a minute for one cycle. But the disadvantage of the method is the impossibility of immersing instruments of large sizes in the instrument. Therefore, its popularity of electric glossper sterilizer earned in dental clinics and beauty salons.

Stages of processing tools

The whole process of processing tools for hospitals is a very complicated procedure, requiring compliance with all of its stages:

- Disinfection and presterilizing cleaning of instruments.

- Processing and sterilization of medical equipment at the place of their use, for example, in an outpatient clinic.

- Packaging.

- Directly the sterilization process itself.

- Storage and further transportation of sterilization material to the places of use.

Steam sterilizer

Medical autoclave is a special equipment in which the processing of tools takes place under the influence of steamunder high pressure.

Medical institutions, organizations of the pharmaceutical and cosmetic industries, and laboratories that have a research area are supplied with steam sterilizers.Modern autoclaves are equipped not only with automated control, but also with electronic programming of operating modes.

Medical autoclave sterilizers are a tank with a thick hermetic walls, equipped with a faucet, designed to release steam, a pressure gauge that measures the vapor pressure inside the device and an additional valve to release air formed over the set values.

In addition, the device is equipped with a thermometer to monitor the temperature during the process and a steam boiler to heat the water.

Work with such equipment should be staff who have undergone special training. Steam devices require the utmost attention and compliance with clear instructions.

The mode of sterilization in the unit is chosen strictly taking into account the material being processed, in units of overpressure and the required length of time for the procedure. For example, dressings and surgical instruments are treated at 1 atm for 30 minutes.

Types of autoclaves

Medical autoclaves with a chamber volume not exceeding 54 liters, taking into account European standards EN 13060: 2004, can be divided into 3 types - N, S, B.

- Autoclave speciesN. The model is designed to handle unpacked fabric items, metal tools with a smooth surface, plastic dishes that can withstand temperatures over 100 degrees.

- Autoclave speciesS. Models are equipped with a vacuum drying function. A sterilizer of this class is used when it is necessary to process a dental and medical instrument with a smooth, porous or soft surface, but not in large quantities. The device is used in medical and dental establishments in cases when sterilization with more serious installations is not required.

- Autoclave speciesB. Models are equipped with vacuum drying and fractional pre-vacuum function. Possess excellent penetrating power of hot steam. Therefore, in such devices you can handle any tools, packaged or not. Products can be made of various materials. Their shape can be any, smooth, porous, massive. To sterilize dental handpieces, only such models should be used.

Types of autoclaves

By way of loading autoclaves can be divided into:

- vertical;

- horizontal.

By the method of removing air from the sealed chamber on:

- gravitational;

- forevacuum.

Advantages when using autoclaves

Sterilization of medical devices after their use avoids contagion of patients with infectious diseases, infection with dangerous diseases. Autoclaves have several advantages:

- Sterilization is carried out at low temperatures. They can handle tools made from materials that do not accept high temperatures.

- High efficiency. Autoclaves, especially class B models, have good penetrating power. This allows you to sterilize products from any materials and sizes.

- Low maintenance. Due to the short cycle and low power consumption, autoclaves can save on their use.

Additional disinfection equipment

For a better sterilization procedure and delivery of “clean” instruments to their destination, the medical industry is ready to offer additional equipment.

Washing machines

Presterilization treatment is necessary in order to clean the medical instrument from such contaminants as blood, fats, drugs, proteins, and also to prevent the growth of microbes.Such machines make it possible to fully automate the entire process, which saves medical institutions not only money, but also time.

Instrument Packaging Machines

Required for packaging products that have undergone presterilization processing. To be able to redirect them for further processing in a special container.

Distillers

Distilled water is used in autoclaves instead of ordinary water for sterilization.

Conclusion

It is known that many diseases are transmitted due to poor sterilization. Today there are many types of specific equipment that are used to process medical instruments after they are used. Medical equipment for sterilization was created not only to enable reuse of instruments in hospitals and clinics, but also for processing medical waste for the purpose of their further disposal.

/rating_off.png)