How to choose a generator for welding

When performing construction or repair work in most cases welding of metal parts or structures is required. It is good if these works are carried out near electrical networks to which welding equipment can be connected. In the absence of sources of electricity, generators come to the rescue, having gasoline or diesel engines and operating autonomously.

Content

What is a welding generator

There are 2 types of power generators available that can work with welding equipment: welding and synchronous.

A welding generator is a power plant that combines 2 units: a welding machine and a conventional electric power generator.

To prepare such a device for operation, it is enough to connect cables to it, one of which has a holder for electrodes, and start the engine. Additional equipment for welding is not required. Due to ease of setup and use, welding generators are widely used by construction organizations and utilities. Also these units are used when performing a large amount of welding work and for laying pipelines in places remote from the power grid.

Synchronous generators They are a source of voltage for both transformer welding machines and inverter welding machines.

Generator synchronous OS-71-U2

It is important to know that a conventional standard power plant is often not suitable for connecting a welding machine to it, since it requires certain power parameters. Although short-term use of a standard station is possible, but in most cases it leads to its failure.

The classification of power plants is carried out according to the type of engine.These units can operate on both gasoline and diesel fuel.

Gasoline generator

This type of electric generator is the most popular among professionals and home craftsmen. It can have a gasoline two-stroke or four-stroke engine. The device has a low power and is used for work with minor loads. In addition, the welding gas generator is different improved current performancewhich positively affect the quality of welding.

Power petrol models range from 2.5 kW to 14 kW. The volume of the tank in gasoline units is also small - about 4-25 liters. This type of generator is capable of delivering a maximum current in the range from 160 to 300 A and can work with electrodes up to 5 mm in diameter.

Generator petrol GE 4000

Pluses of petrol units:

- acceptable cost;

- small weight (from 50 to 100 kg);

- ease of use;

- the ability to run and work at low temperatures.

Cons petrol units:

- short service life, from 500 to 3000 hours;

- high fuel consumptionfor example, a 4 kW unit will, on average, consume from 1.7 to 2.4 liters of gasoline per hour;

- the generator must be allowed to rest after a certain time (indicated in the instructions for the device).

Diesel generator

Allows you to perform welding work with large loads and has a long working life. For domestic purposes, diesel units are not suitable because they have a capacity of from 6 to 16 kW and high cost. Stationary units can have a power up to 80 kW.

Diesel Generator TSS SDG 5000 E

Diesel power plants have fuel tanks with a capacity of 12 to 65 liters, amperage 160-520 A and can work with electrodes up to 8 mm in diameter.

Pluses of diesel units:

- service life of about 40,000 hours;

- stability of work;

- metal welding at high loads;

- high efficiency;

- lower fuel consumption in comparison with the gasoline type of the generator, about 1.6 l / h with a power of 4 kW;

- diesel unit can work without interruptionalmost around the clock.

Cons of diesel units:

- engine difficult to start at low ambient temperatures;

- big weight (from 100 kg and above);

- high cost (more than 100 thousand rubles.).

Criteria for selecting a generator for welding

Above were considered welding generators, which are, as already mentioned,a mixture of welding machine and power for him. But there are cases when it is necessary to power the welding machine from an autonomous power station. What kind of generator is needed for a welding inverter or a transformer type unit in such situations?

To power the equipment outside the centralized power grid, use synchronous generators with all the characteristics that are acceptable for the operation of welding units. In order to choose such a unit correctly, the following parameters should be taken into account: power, current strength, diameter of electrodes, compatibility with inverter devices.

Power

Power is calculated by the formula Pmax = (Imax x Ud) x Efficiency, where:

- Рmax - the maximum value of power consumption by the unit;

- Imax - maximum current of the unit for welding;

- Ud - welding arc voltage;

- Efficiency - has a value of about 0.85 (for inverters).

For example, if your welder can produce a maximum current of 160 A, then substituting the numbers in the formula, we get the value of the maximum power consumption: Pmax = 160 x 25 / 0.85 ≈ 4.7 kW.But since the unit cannot work all the time at maximum power, it is required to calculate its average value using the formula: P cf = Pmax x DF. Where:

- P cf - the average power;

- Pmax is its maximum value;

- PV - the duration of switching on the device (on average, this value does not exceed 40%).

Substituting the values in the formula, you will find out inverter rated power: P cf = 4.7 x 0.4 = 1.88 kW.

But it would be better if the generator for the welding machine will have reserve power. It is desirable that it exceeds the nominal by 25-35%. That is, 1.88 + 0.35 ≈ 2.5 kW - this is the required power. As for diesel-type units, their power should exceed the power of the welder by 30-50%.

Important! Calculating the parameters of the unit, you should know that the power consumption of the welder is measured in kW. But some manufacturers are misleading consumers by indicating this parameter in kVA (kilovolt-amperes). It is possible to transfer kVA to kW according to the formula: 1 kW = 1 kVA x KM, where KM is the power factor, which can be in the range from 0.6 to 0.7.

For example, you need a generator with a capacity of at least 2.5 kW. A commercially available unit, which says that its power is 3 kVA. If you apply the above formula, you get: 3 x 0.7 = 2.1 kW.This means that this unit has less than the required power, and it will not pull the inverter welding machine.

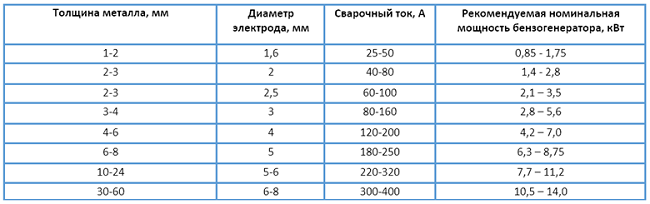

Also, the change in the above parameters is affected thickness of the metal being welded. To quickly make calculations, you can use the table below.

Welding current strength

For an inverter type welder, it is permissible to use a generator of lower power than is required. But first, you need to correctly calculate the minimum amperage, which will allow welding without changing its quality for the worse.

For example, you are going to connect invertor welding to a 4 kW kW generator. To calculate the minimum current there is a formula: Power x Efficiency / arc voltage. Substituting into it the numerical values, you get: 4000 x 0.85 / 25 = 136. Based on these calculations, you can understand that using an inverter with a 4 kW generator, you can cook up to 136 A.

Electrode Diameter

This parameter is also important, and it should correspond to the minimum power of the generator. Professionals advise to the diameter of the electrode add a factor of 0.5. For example, if you use electrodes with a diameter of 3 mm, then 3 + 0.5 = 3.5. This means that for a 3 mm electrode, you should choose a generator with a minimum power of 3.5 kW.

Inverter compatibility

It is very important that the gas generator for welding with inverter has compatibility with the latter. I mean, I had suitable type of sockets to connect equipment. Household inverters will be sufficient to have a 220V outlet. But for the equipment of the pro class, a voltage of 380 V (three-phase) and the corresponding type of outlet will be required.

Overview of popular models of welding generators

Thanks to the combination of a generator and a welding machine, these units are widely used in construction and in the performance of repair and construction works. Next will be considered several of the most popular models of devices in this category.

Gesan GS 210 DCH

The three-phase gasoline welding power generator is a powerful and reliable device from the Spanish company Gesan.The unit is equipped with a HONDA (Honda) engine with manual start, has a power of 3.5 kW and can produce a welding current in the range from 40 to 220 A.

The capacity of the fuel tank for this unit is 6.5 liters. Average fuel consumption is 2.8 l / h. Gesan GS 210 DCH equipped with wheels and handles for convenient transportation. The basic package includes cables (welding and with a clip), 4 and 2 m long.

Kraton GWG-5.0 / 180

Welding station equipped manual and electrostart. It can be used as a backup power source in the absence of a centralized power supply or disconnecting it. The station also has a 12 V output for charging batteries.

The unit produces a welding current ranging from 50 to 180 A and has a maximum generator power of 5.5 kW. Electrodes with a diameter of 2 to 4 mm can be used with this unit.

Telwin Motoinverter 254 CE

This is an invertor welding station for MMA and TIG welding.

It is important to know! The MMA welding method is manual electric arc welding. The TIG method is welding in argon, non-consumable electrode.

With this unit, you can use both conventional electrodes and rutile-coated electrodes, as well as electrodes for direct current.

The device has a generator power of 8.2 kW, welding current from 5 to 230 A and a mass of 78 kg. In addition, the station has:

- four-stroke engine with protection blocking it in the absence of oil;

- stabilization of the welding current (with possible fluctuations of the output voltage);

- the “Arc Force” function, which allows to adjust the arc force;

- hot start and electrode sticking functions;

- engine speed limiter;

- thermal protection;

- the ability to switch modes (welding / generator).

The device can also be used as a power source. for power tools.

Top Synchronous Generators

Below are the generators that can be used for welding machines, and for solving various household tasks to provide electricity.

Huter DY6500L

Huter DY6500L is a quality unit that can run on both gasoline and natural gas. The power of the power plant is 5 kW, which is enough to use this generator for welding with inverter, for example, brand Svarog ARC 205 (J96).

On the front of the device there is a voltmeter, 2 sockets for 220 V and one for 12 V.

BRIMA LT 8000 B

The unit can be used as an independent power source in the absence of electricity in the country or in a private house. Also BRIMA LT 8000 B often acts as a generator for welding equipment.

The power station is equipped overcurrent protection and overload systems. The maximum generator power in this unit is 6.3 kW.

Important! This electric generator for welding works well in tandem with the device (inverter) Resanta SAI-190.

ERGOMAX ER 5400

The generator is a great solution for the inverter KEMPPI Minarc EVO 150.

The device is equipped with overload protection, different low gas mileageIt has a power of 4.5 kW and a weight of 70.7 kg.

Endress ESE 606 HS-GT

The power plant has a roomy tank (18 liters) for fuel, which makes it possible for the apparatus to last for a long time without refueling.

The unit has a 4-stroke engine, a powerful generator - 6.4 kW, fuel consumption 2.2 l / h and tank capacity for fuel 18 or 30 liters. The power plant is often used with a EWM Pico 162 welding inverter.

Summarizing, we can say that this equipment is widely used in various fields of human activity. And the demand for it continues to grow from year to year,since the key feature of the apparatuses is their complete autonomy, without which it is impossible to do on country construction or during repair work in field conditions. When choosing a machine, first of all focus on its quality, and after that - on the price. You should buy products known and time-tested manufacturers. Only with this approach you will receive equipment that guarantees long and trouble-free operation.

/rating_off.png)