Functions and types of vacuum pumps for air conditioning

Vacuuming a split system is a very important step when installing an air conditioner. If the installation of any element of the system to hold correctly, the device will very quickly become unusable. A vacuum pump for air conditioners is responsible for removing air from the pipes leading to the indoor unit of the system, as well as from the innermost unit. During the operation of the device, a significant amount of vapors are formed, which, if improperly removed, can mix with the oil inside. And this in turn will lead to a quick breakdown of the air conditioner due to compressor failure. Therefore, the correct conclusion of air and vapor from the air conditioner is very important.

Content

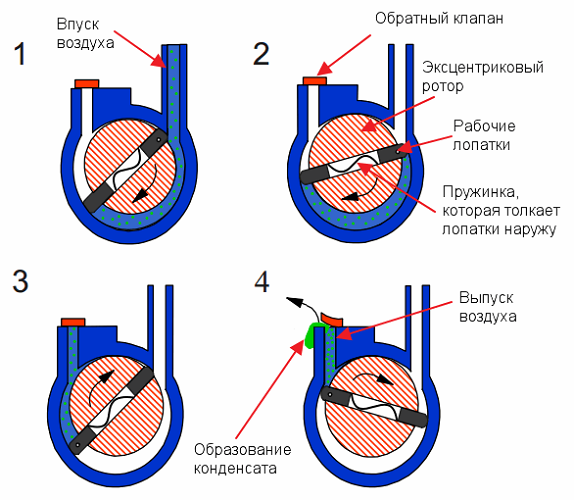

The principle of operation of the pump for pumping air

As it became clear, the main task of the vacuum pump is the elimination of water and gas vapors. How does this happen? There may be two principles of action: the air masses are either removed outside the air conditioner, or are connected.

In either case, the result will be a vacuum in the air, a decrease in pressure, which leads to a decrease in the boiling point of the liquid.

When happens vapor removal, a certain part of the air mixture is isolated and moves to the exhaust pipe. At binding Some of the gas molecules are deposited on a solid surface or move with a stream of liquid or vapor, which leads to the necessary vacuum. Due to such processes, the liquidation of excess liquid and gaseous mixture in the split system is performed.

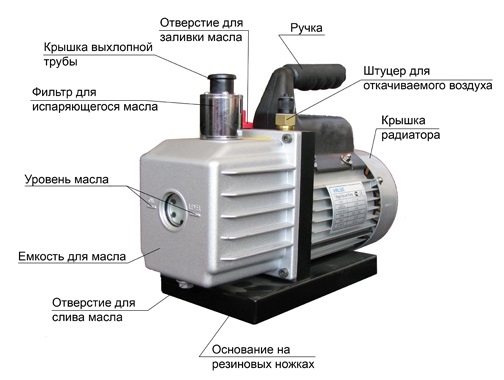

The principle of operation of the plastic rotary pump with oil sealer

Existing varieties of vacuum pumps

Today, manufacturers offer a variety of options for vacuum pumps for air pumping, which can be divided into the following groups.

- The most common option is rotary vane aggregate. These models do not create a lot of noise when working, are easy to operate and differ in a not too complicated design. The disadvantage of such pumps indicate the need to replace consumables, such as oil.

- Low-vacuum two-rotor or two-stage pumps attract with their high performance, as they are equipped with two rotors, which allows to save when using.

- Low vacuum liquid ring pumps they are characterized by simple designs and no need to fill the oil. But such models when organizing air conditioning require a large amount of water and consume a lot of electricity.

- Diffusion or high vacuum pumping pumps. They are characterized by increased performance, but very afraid of pressure surges.

- Cryo-adsorption high-vacuum models, the robot which is based on the absorption of gases at lower temperatures of the material that is on the surface. Despite their excellent technical characteristics, such pumps are used quite rarely, since they require the use of synthetic oils.And they, in turn, strongly pollute the elements of the system, which requires additional cleaning.

- Heteroion high vacuum options characterized by high performance and efficiency in cleaning. But their use is very rare, since such units are quite expensive.

How to choose the most suitable option

When choosing a vacuum pump, you should take into account many aspects and take into account the technical characteristics, operating parameters of the unit and the entire split-system. Consider what needs to be considered in order to choose the most appropriate vacuum pump.

- The period of uninterrupted operation of the unit, since it must as quickly as possible pump out the entire volume of air from the “refrigeration circuit”. This time should be sufficient. The maximum duration of the procedure for the formation of a vacuum during operation does not exceed half an hour.

- Power vacuum pump. The rate of complete pumping directly depends on this indicator. Thanks to power, it is possible, in principle, to compensate for a small time of continuous work.

- Length of the "refrigeration" circuit. Power and the period of continuous operation of the device depend on it.It turns out that the longer the contour, the longer the time of uninterrupted work and the power of the unit.

- Pump performance. This parameter must fully correspond to the volume of air that will need to be removed from the system. The most common performance for modern drainage pumps is in the range of 40-150 cubic decimeters / minute. It turns out that the most powerful pump model is capable of removing approximately 4 and a half cubic meters of air over a period of continuous operation.

Additional selection criteria

In addition to these technical parameters, the following points should be considered when choosing a pump:

- the pump must guarantee a certain level of pressure, which will allow to use the selected air conditioner effectively for a long time;

- the unit must be convenient during operation (low weight, the presence of an indicator to determine the oil level, not make noise, do not vibrate, etc.);

- possibility of operation of the pump under various conditions.

In a word, a vacuum pump for air conditioners should be chosen as robust and powerful as possible, with good performance, in order to guarantee the user to pump air masses out of the “refrigeration” circuit in 15-20 minutes of work.

Sometimes it happens that in the process of vacuuming it will be necessary to carry out the pumping of air several times, as leaks sometimes appear.

Every person who intends to organize a split system in his housing should take the issue of installing an air conditioner very seriously and select the highest quality and productive elements for the functioning of the entire system.

/rating_off.png)