DIY Scale Weighing Repair

Everyone can repair the floor scales with their own hands. Well, or almost everyone, because it is not difficult. Basic knowledge of electrical engineering and the presence of a small locksmith experience will be enough for this.

Content

We repair electronic scales

Preparatory work

Any repair begins with the determination of the malfunction. Troubleshooting includes:

- battery check;

- appearance inspection;

- checking all electrical contacts;

- check the status of parts of the scales.

Battery Check produced in the very first place. If the scale does not turn on or shows fuzzy numbers, check the power supply status. This is done simply.A battery comes out and if there is no tester, it is inserted into another electronic device with similar power. If it works, then the reason is different.

When conducting an inspection, two factors must be considered:

- Even if the battery works in a different device, it does not mean that it will work on the scales.

- Due to improper long-term storage, for example, at high humidity, its contacts may oxidize. In this case, it is enough to simply wipe the battery with a flannel, and it will work again. But the most reliable test is performed by the tester.

Inspecting the appearance weights, you need to pay attention to the changes in them. Observed cracks, charring, deformed parts and other deviations from the original state indicate the location of the fault.

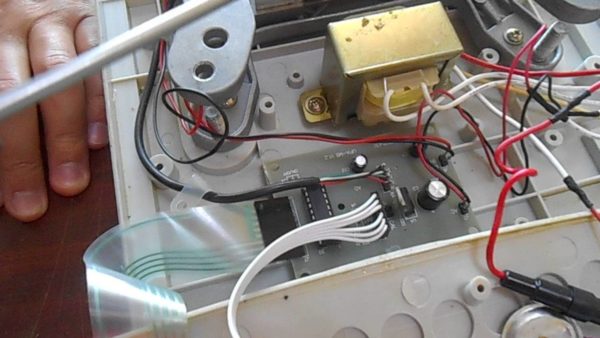

Electrical Contact Check often helps to immediately repair the scales. If a torn wiring is detected, it must be soldered to its place. Also come in case of damage to the track on the board.

Checking the status of parts of scales done very carefully using exact tools. Here you will need a caliper, level and angle.Attention is drawn to the absence of deformation of the inner frame, the state of each part. A close inspection may reveal a hidden defect.

When the fault is found, you need to prepare a tool to fix it. Required minimum:

- pliers;

- screwdrivers;

- soldering iron;

- tester.

To remove dust and dirt will need a clean cloth. If you have to restore the tracks on the board, then you should prepare a sandpaper, solvent and varnish. When all this is prepared and laid out, you can start repairing electronic scales.

Repair plume

What to do if weighing the same item displays different results on the display? The answer is one - start repair.

After checking and making sure that the batteries are in good condition, proceed to disassembling the scales and carefully examining the cable - wire setconnecting the electronic board to the display. As a result of the weakening of its contacts, the display is de-energized, the numbers on it are not visible. In this case, it is necessary to increase the density of junction of the cable and its contacts to the electronic board. To do this, you need to slightly lift up and press to the display in a bar of dense material.You can cut it out of wood or use a school eraser. This homemade part will act as a board lock. The contact will be restored, the device will start working. When a broken wire is found in the cable, it should simply be soldered in the place of the break.

If the need for repair is caused by a change in the state of the display (black smudges, air bubbles, stains), then there is nothing to do with the loop, and the display must be replaced.

Strain gauge sensors

The next object of repair of electronic floor scales will be strain gauges. This small-sized module converts the magnitude of the deformation into an electrical signal, which, passing through an electronic board, turns into a digit on the display.

The scales are mounted 4 such sensors: one in each leg. They are not destroyed by mechanical impact, but sometimes there is a wire breakage at the output of the sensor. Broken wire is soldered. Sometimes it is difficult to make it because of the small size and high strength of the case in which the sensor itself is located. It will require ingenuity and perseverance along with patience. But the strain gauge will be restored.

And it rarely happens that the sensor itself fails. Such a fault is determined by the tester - the method of piercing. In case of a negative result, its elimination is carried out by replacing it with a working sensor.

Mechanical damage elimination

Mass impact on the scales above acceptable, will also cause them to break. This is due to the bending of the internal frames, in the corners of which strain gauges are embedded. Such a breakdown does not occur often. Determination of the presence of deformation can be done by measuring or using a caliper. Repair in this case will be simple - you need align the bent frame. The electrical balance of the strain gauges will be restored, and with it the operability of the device as a whole.

It is not recommended to align the frame without removing it from the scales.

Calibration

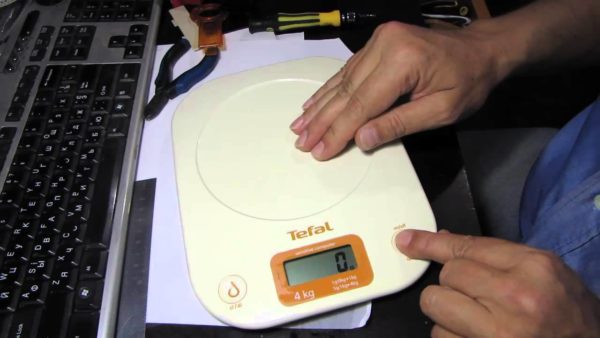

The accuracy of the readings of the scales directly depends on their calibration. In case of its violation, the performance will not be disturbed, but they will be measured mass show wrong.

You can restore the calibration as follows. The reference weight is set on the site. It can be any item whose weight is exactly known.Then the power button is pressed and held in this state until CAL appears on the display. After a while, the display will highlight the word PASS. After that, the inscription is deleted, and the device turns off. This is the only way to restore electronic do-it-yourself calibration.

If it does not help, calibration is performed. only in the service workshop. Why so? The fact is that the calibration process is performed with special devices that are not used at home.

The reference weight cannot weigh more than the permissible limit for weighing the balance.

Scale cleaning

Often, electronic scales stop working due to dust and dirt entering them. Repair in this case is very simple: they must be opened and cleaned carefully. For these purposes, you can use rags and small tassel. The work must be done very carefully, so as not to accidentally damage the parts of the electronic board.

Using the material of the article and the submitted videos, there should be no questions about how to repair electronic scales.

We repair mechanical scales

Many owners of mechanical scales are also sometimes concerned with the issues of their repair.It is appropriate to note here that their device is so simple that there is practically nothing to break! Damage can only be metal. load-bearing elements. Trouble may occur when attempting to disassemble the case. Four springs tightening the casement cushions are installed in their place and that's it. Repair made. The parts that fell out in this case are also returned to their original place with tweezers. He also installed the spring. After such a simple repair, the floor scales work again.

When installing loose parts, it is necessary to compress the case, as they are held in place by the force of compression.

The simplicity of the device electronic, and especially mechanical floor scales makes it easy to do their own repair. The only thing that is required in this process is care and accuracy, since all the details of the scales are very small and delicate. Timely and proper repair will prolong the work of the necessary device.

/rating_off.png)