Terms of use of the construction stapler

The construction stapler is a multifunctional mechanism. They are used when necessary to connect the same or different not very hard materials with each other, for example, plastic, wood, film, insulation, plywood. This tool is called differently: Tacker, staple gun, stapler, nailer, staples. Fastening of separate elements among themselves is carried out with the help of brackets, studs or small nails. To know how to work properly with a construction stapler, you need to deal with its design, the types of fasteners suitable for it, the method of setting and replacing brackets.

Content

Device and principle of operation of the construction stapler

Furniture stapler is widely used by builders and furniture makers, as well as representatives of other fields of activity. By type of energy used for the implementation of the shot during operation, there are the following types of takers:

- mechanical;

- electrical;

- pneumatic.

The first two types are intended for home use, and the last type of tool is considered professional and is used mainly when working in large volumes. The principle of operation of mechanical and electric staple guns is based on pushing the fastener by force of the cocked (compressed) spring. After pressing the trigger, it opens up, which causes movement of the striker. He hits the bracket (nail or hairpin), driving it into the surface of the material.

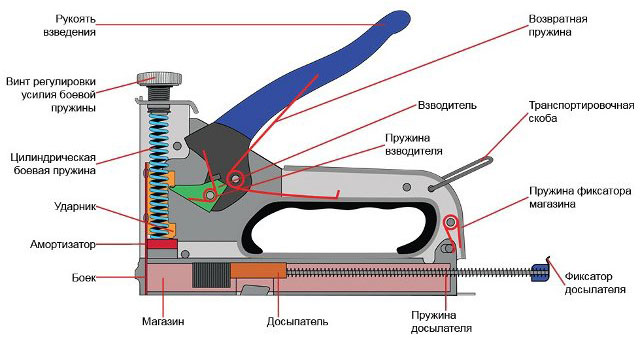

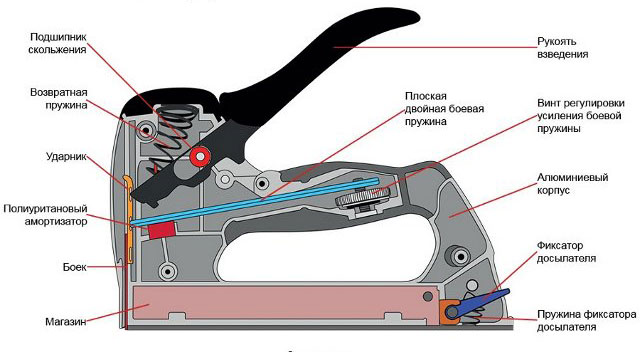

Mechanical Stapler Design

Manual (mechanical) staplers differ from their analogs in a simpler design. They consist of the following components and parts:

- platoon handle;

- safety guard to protect against accidental shots when transporting the tool;

- shock mechanism springs;

- shock absorber;

- drummer;

- striker;

- impact force regulator, which provides the ability to work with materials of different degrees of hardness (different density);

- enclosures;

- platoon spring;

- shop under fasteners;

- rammer (with spring and lock);

- the tip allowing to hammer in precisely fixture.

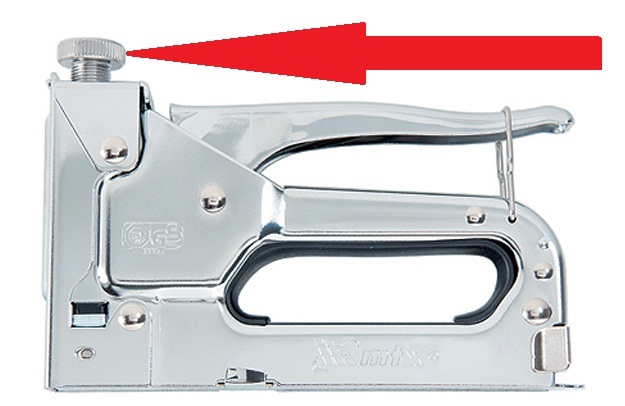

Diagram of the device stapling gun presented in the photo below.

Impact mechanism - This is the main node of the stapler, cocked by the strength of the employee’s muscles. It can be equipped with two types of springs:

- twisted;

- spring (lamellar).

Manufacturers indicate in the operating instructions for the products a type of installed spring.

Twisted spring mechanismPresented in the photo above, equip cheap models. They can be easily distinguished by the adjusting screw located on the tool body on the opposite side from the opening of the departure of the brackets. But it is also possible that the lamb will be absent, then you will need to refer to the instructions to determine the type of spring installed.

Leaf springs more powerful, but more expensive than twisted analogues.At the same time, the return on the instrument they have equipped during operation is less. They also have a large operational resource and are cocked easier. The lamellar spring mechanism is installed on the models intended for professional use.

For convenience of working with the tool, the handle is covered with rubber overlays, and the shop is made with a transparent insert (which helps to easily control the presence of staples or nails).

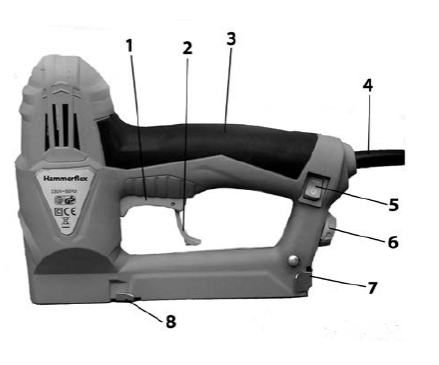

Design features of electric and pneumatic staplers

The device of the electrical network stapler is shown in the photo below.

The numbers in the photo correspond to the following structural elements:

- trigger;

- fuse;

- handle with a special coating;

- power cord;

- on / off switch;

- impact force regulator;

- pusher mechanism;

- score.

Inside the instrument is located electric and impact mechanisms. In this case, the electric motor is designed for cocking the spring.

There is no power cord in the battery models: instead of it, batteries are installed.

The device of the furniture stapler of pneumatic type is more difficult than mechanical analogs.Pneumatic tool consists of the following structural elements:

- enclosures;

- a cylinder with a piston located inside it;

- launch systems (trigger mechanism);

- shop for fasteners with pusher;

- impact mechanism;

- an inlet connection for connecting a high pressure hose to the tool;

- regulator of penetration depth fasteners (force of impact);

- air distribution unit.

The pneumatic type shooter is powered by compressed air supplied by the compressor or from a cylinder. After pressing the trigger gas passes the air distribution node. Next, the compressed air enters the cylinder, while driving the piston. The latter transmits energy to the striker striking the fastener. After impact, a staple or nail is driven into the surface of the material.

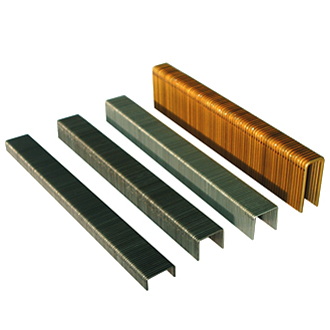

Classification used brackets

To use the stapler, you need staples. They are divided into separate types according to the following criteria:

- on the material from which made;

- according to the degree of hardness;

- by the presence of the coating;

- in size;

- according to the form.

By production material

Staples on the material are:

- aluminum, used in working with non-solid materials;

- copper (expensive), also intended for soft parts;

- steel, suitable for both soft and soft materials, but rusting over time;

- from a stainless steel (stainless steel) is a reliable option in the most different conditions, but differing in the high price.

Brackets for furniture can also have a galvanized coating, which prevents them from rust.

By hardness

By hardness fasteners are divided into the following types:

- plain;

- very hard;

- red-hot.

The ends of the fasteners can also be sharpened differently, making it easier to drive in under certain conditions.

In form

Based on the form of brackets, there are the following types of them:

- U-shaped;

- U-shaped;

- T-shaped (pins).

Most often in practice fasteners are used in the form of the letter P, and U-shaped are used mainly during the laying of cable lines. The pins are almost inconspicuous fasteners. They are used when fasteners should be as invisible as possible.

Standard sizes of brackets

Almost all manufacturers of takers also produce their own brackets for them. But at the same time there is a mandatory standardization of standard sizes of products - this allowswhen replacing insert the staples in the staple gun from different companies.

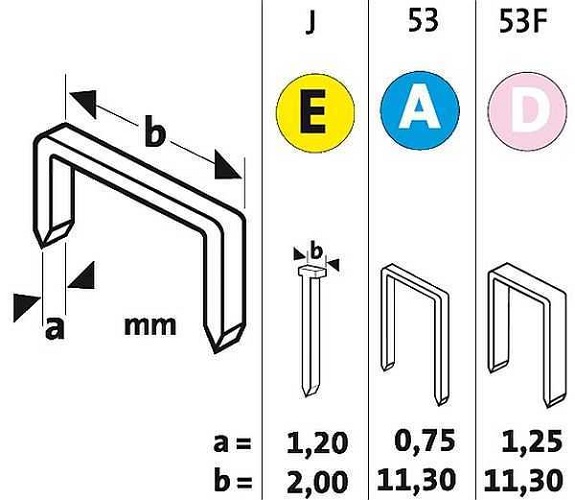

Under the size of fasteners understand these options:

- the thickness of the bracket (denoted by the English letter a);

- the length (width) of its back (b);

- leg height (depth).

Based on these dimensional parameters, select the following types of staples most popular in practice.

- 53 is the most common standard size with a = 0.7 mm, b = 11.4 mm and the height of the leg being 4 ÷ 14 mm.

- 140, having the following dimensions: the back width is 10.6 mm, the thickness is 1.2 mm and the depth is from 4 to 14 mm.

- 36 - This marking indicates that U-shaped fasteners can be used for stapling.

- 300 are nails that are only suitable for staple gun.

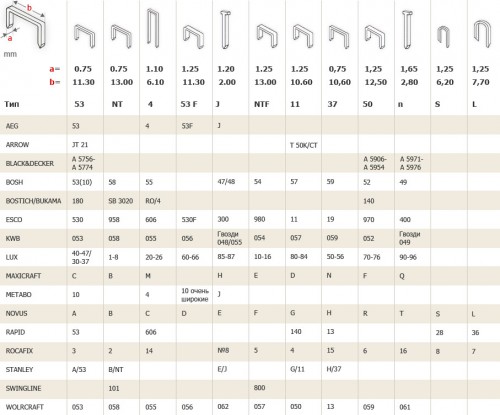

It should be noted that different companies have the same types of fasteners are indicated differently. To compare fasteners from different manufacturers, use the table below. By the size to determine the brackets do not make any difficulties.

There are no universal types of fasteners suitable for any work.

It is recommended to use high-quality consumables, which are advised by the manufacturer of the operated model of the staple gun.

How to insert staples in the stapler

Changing the staples in a mechanical tacker is easy. To charge a new fastener, proceed as follows:

- the tool is blocked from being accidentally turned on with a fuse;

- on the rear side of the scraper, open the lid of the magazine, behind which there is a groove for fasteners;

- from within reach the core equipped with a pusher spring;

- the rail of the brackets turn the tips against the handle, and then inserted into the groove;

- set inside the tool rod with a spring to its original place, where they clamp the fasteners;

- close the lid of the store;

- remove the fuse;

- make several shots in test mode to test the performance of the tool.

With nails when charging the stapler do the same way.

The photo below shows how to put the staples in the mechanical stapler.

Blocking a staple gun from an accidental shot is a mandatory procedure that ensures the safety of work.

In order to staple pneumatic or electric staplers, operate along the same scheme as with a mechanical tool:

- block the device;

- turn the tool;

- pressing a special button, take the tray under the fastener;

- properly insert staples or pins (nails) into the tray;

- insert the "clip" until the click;

- unlock the tool and check its operation.

When you press the stapler button, the tray for fasteners can either open or open its lid - this depends on the stapler model used.

Some modifications of mechanical staple guns have a different principle for replacing fasteners: they are made with a chute extended when the button is pressed. The staples are placed in the extended tray and inserted back into the magazine until they click. The whole process, which shows in detail how to fill up the brackets in the considered case, is demonstrated in the video:

Staple adjustment sequence

Setting the staple gun is needed in such cases:

- after buying a tool before starting work;

- if the stapler stops completely driving in fasteners;

- when you start working with a material of a different density than the previous one.

If the stapler ceases to drive in fasteners completely, this is due to a gradual shock spring wear either with his loosening.Until some time, the regulation will help, but after that it will be necessary to purchase a new staple machine.

It is necessary to take into account the dimensions of the fasteners for which the tacker is designed: if the size of the brackets exceeds the allowable according to the operating instructions, then the adjustment is nothing to do with, just need to choose the appropriate consumables.

Mechanical staple guns with a twisted spring have a screw that regulates the degree of its compression. It is shown in the photo below by a red arrow.

If the adjusting screw is screwed in a clockwise direction, then the spring will shrink more and its potential energy will increase. The result will be a bigger blow. An ejected staple will go deeper into the surface of the material. When the knob is turned counterclockwise, the spring will weaken. The blow will also become weaker. Performing the rotation of the screw, you can configure the stapler to work with materials of different hardness (density).

In mechanical models of scissors with a spring (plate) spring of the percussion mechanism, the regulator is located under the handle. Rotating it in different directions, perform the regulation of the force of the shot.It is required to re-tune the percussion mechanism each time, starting to work with another material. After the adjustment of the compression of the spring is performed, it is recommended to check the operation of the tool on the workpiece, which is no longer needed.

The adjustment process ends when the fastener with the entire length of the legs enters the material, without piercing it with a “back”. It is recommended to exercise by rotating the regulator from minimum to maximum compression of the spring.

Rules for safe operation of the instrument

When working with a construction stapler, it is imperative that you follow the safety instructions. The basic requirements are as follows.

- When replacing staples you need block tool using a fuse against sudden, unexpected switching on.

- It is forbidden to instruct the instrument on the arm or another part of your own body, as well as on other people or animals.

- When transporting or storing the stapler, it is necessary to fix its handle with a fuse.

- Only a person in a normal psychological state (not under the influence of alcohol, psychotropic substances or drugs) is allowed to work with a scissors.

- The workplace must be well lit and kept clean.

- It is necessary to constantly use such personal protective equipment like glasses, so that nothing accidentally flew into the eye. So that when the clip is fired, it does not fly off, it is necessary to monitor the presence of metallic inclusions on the working surface, bypassing or removing them in a timely manner.

- If the fastener is stuck, it must be carefully removed.

- When working with small workpieces, they need to be fixed motionless using a vice or clips, it is forbidden to hold them with your hands.

- Body position should always be stable and as comfortable as possible, and shoes - with non-slip soles.

Safety Instructions with electric and pneumatic staplers contains additional items:

- Power tools should not be used inside hazardous areas;

- it is allowed to connect only switched off equipment to the socket;

- the power cord with plug and case of the operated model must be intact;

- It is forbidden to use an electric staple gun in the rain or indoors with a high level of humidity;

- unauthorized persons should be at a distance of more than 2 m;

- used pneumatic tools, high pressure hose to it, as well as other parts of the system must be without mechanical damage;

- during the work it is necessary to ensure that the power cord is located behind the tool so that it does not interfere.

There is nothing difficult when using mechanical, pneumatic, and also electric types of construction staplers. It is only necessary to use suitable (specified in the instruction manual) fasteners for work, and in front of it adjust the impact mechanism for a specific material. At the same time the constant observance of safety precautions will prevent injury. Attentiveness and accuracy - this is one of the main guarantees of high-quality performance of any work.

/rating_off.png)