How to choose a construction stapler

A construction stapler is a relatively simple, but at the same time multi-functional tool. It is charged with staples or nails, with the help of which different materials are nailed, for example, film, chipboard, wall paneling. At its core, the device is more powerful. analog clerical stapler. There are products on the market that use various sources of energy for their work. To choose the right tool among the variety of modifications, you need to know the advantages and disadvantages of each type, as well as take into account the nature of the upcoming work.

Content

Scope of the tool

The construction stapler, due to the different fasteners used and functional features, has many other names, the main ones being as follows:

- staple gun;

- nailer;

- scraper;

- Tacker;

- stapler

The device in any case performs the following tasks:

- connects the same parts to each other, with the brackets being bent;

- joins together different materials, such as plastic, plywood (nails them).

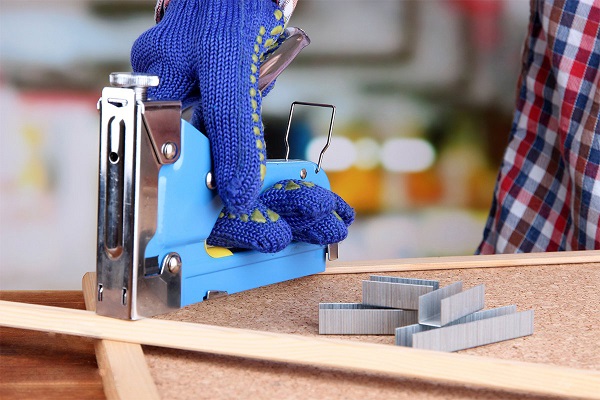

Staple gun was widespread among furniture makers, builders, decorators. The device during the work can be easily held in one hand. In practice, it replaces the hammer, while efficiency and productivity increase, while workers are less tired.

With the help of stapler, the following work is done:

- roofing;

- beadings are attached to the windows;

- heat insulation, roofing material, film and similar materials are attached;

- wire and cable are fixed to the surface of different materials;

- do drapery;

- attach furniture upholstery and decor;

- collect or repair pallets;

- perform facing work;

- Sheets of plywood, chipboard, OSB, DVP and other sheet materials are connected to the frameworks.

Furniture stapler, like other types of tools, allows you to perform many more different working operations. In many cases, when something is required to attach, you can use the shooter. The device is constantly used for upholstery different materials.

The main criterion for dividing staple guns into separate groups is the type of energy that forms the basis of their operation.. On this basis there are the following types of staplers:

- mechanical;

- electrical;

- pneumatic.

Each type of product has its own characteristics (pros and cons) that define the area of application. Consider which tool is best suited for a particular type of work.

Mechanical models

Mechanical type staple guns are products with the simplest device when compared to their counterparts. The mechanism works from hand force effects. The performance of the tool is low, but it differs in relative durability and strength.

Design

Spring - This is the main structural element of the mechanical type of staplers. It can be spring (plate) or twisted type. If the instrument is equipped with a spring of the first type, then it is considered to be of better quality, since its return is lower and less noise is produced during operation. But devices with twisted spring mechanisms are cheaper. It should be noted that the impact force of a mechanical tool is determined by the power of the spring installed on it: the greater its potential, the easier it is to clog into the surface of the shackle.

One of the main components of the tool is also a mechanism that adjusts the penetration force of the device. Adjustment is carried out by a switch or wheel. Regulation provides adjustment of the product under the degree of hardness of the working material.

Some models have a re-strike mechanism: if, during the first pressing, the bracket did not fully enter the surface of the material, then it achieves the second shock pulse to the end.

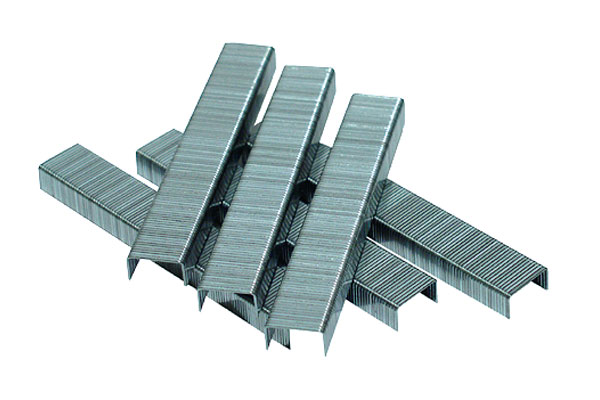

In the machine shop you can insert such consumables:

- U-shaped or U-shaped brackets of different sizes (thickness, length, width of the legs);

- pins;

- small nails.

Staples can be inserted only one of any type or both, there are also modifications intended in addition to nails with pins. The latter option is more versatile and is more popular among builders. But in mechanical devices, the clip under the bracket is small, so the fasteners are inserted only in a small amount. When performing work with solid materials, it is required to make sufficiently large physical efforts.

Advantages and disadvantages

Mechanical devices are simple in terms of Maintenance: it is enough to periodically lubricate the working units. The regularity of making compositions is determined by the intensity of operation and is given in the instructions. In this case, the most simple types of lubricants are suitable.

If we consider mechanical professional stapler, then it is quite expensive, but it has great power. This allows you to work with solid materials. Such models withstand high operating loads.They are almost comparable with electric and pneumatic counterparts in their performance.

The main advantages of mechanical staplers are their low costif we consider options for home use, as well as autonomy. The tool does not have any batteries, hoses, power cords.

Among the three types of staplers, mechanical models are the lightest and most compact. This provides the opportunity to work in hard-to-reach places, as well as in uncomfortable positions.

Electric tool

The electric stapler is more functional than the mechanical counterpart. Useful work is performed by an electric motor. Fastener crashes after pressing the trigger. The impact force of the mechanism is also determined by the power of the installed spring, but only it is stronger than that of mechanical staples, so you can use larger consumables here. Working with power tools does not require much effort.

The product range is represented by network and battery models.

Network models

For the operation of network staplers, a 220 V power supply network is required. In addition, the presence of a cord restricts freedom of movementoften have to use an extension cord. Also, there is a chance that if the instrument and power cord are damaged electric shock. To protect against this, an electric stapler is equipped with a plastic case with rubberized overlays on the handle, and its cord is made with two layers of insulation.

Compared with hand-held shooters, the mass of electrical devices is much higher. Thus, the weight of individual modifications reaches 2 kg.

Electrical modifications of the average price range usually take from 20 to 30 shots per minute. This parameter is important for labor productivity.

Battery Staplers

Cordless tools do not have these disadvantages. It is characterized by mobility, but weighs more network models. Modifications with batteries can use fasteners up to 30 mm long. With one battery charge, you can make about 1000 shots (the rate of fire reaches 30). The weight of the devices is in the range of 1.7-2.5 kg.

Electric bracket for furniture and household use are more expensive than mechanical tackers, and in battery models the price is even higher.Much cheaper battery packers will cost if you buy them without a battery with a charging unit.

Additional functions

Electric professional stapler has a number of accessories and functions:

- device for getting stuck fasteners;

- the ability to control the force of impact;

- a protective mechanism that prevents the possibility of an involuntary shot;

- the possibility of two clips to strike and control the frequency of the pulse;

- the shot is carried out with the tip of the tool pressing on the material.

Household models of this functionality are only partially equipped.

Pneumatic devices

Pneumatic construction staple gun is the most powerful tool of the previously reviewed devices. At the same time the pneumostepler is arranged simply. It is characterized by durability, it is not difficult to exploit. Tool maintenance consists of periodic cleanings.

Device

Nails with staples fly out under the action compressed air energy. There are no springs in this mechanism.Its main working unit is a pneumatic cylinder, into which compressed air is supplied by means of a pneumatic distributor.

For operation of a pneumatic staple gun, a compressor or cylinder containing compressed air is needed.

Industrial equipment also needs electricity. Energy can be taken from the network or from the battery - the latter option is more autonomous.

Operating pressure - This is the most important parameter. It differs in different models. The average value of this parameter is from 4 to 8 bar. Also, the nail-stapling pistol of the pneumatic type is characterized by the expenditure of air to conduct a single shot.

In practice, the following types of pneumatic products are used:

- stationary, where air enters when you press the pedal;

- manual, where the influx of compressed gas is provided by pressing the trigger.

Advantages and disadvantages

The main advantage of the pneumotool, besides power, is its high performance: rate of fire rate - 1 shot per second. In this parameter, the products are superior to electrical with mechanical. By mass, manual pneumatic devices correspond to manual models (its value is about 1 kg).The tool has a compact size.

Pneumatic tools can work with staples up to 50 mm in size. It is also designed for finishing nails and medium-sized fasteners, while the store holds a large number of them.

A pin-stapling pistol, powered by compressed air, besides the functionality of electrical models, also has its own characteristics:

- blocking system;

- device from jamming fasteners;

- the possibility of multiple blows;

- two starting methods (separate and contact);

- shock adjustment.

Some inconveniences during operation are brought by a high-pressure hose from a compressor or a can of compressed air: movement is limited. Also the compressor unit can work noisilythat affects the overall state of users.

The weak point of compressed air products is sealing rings. They quickly wear out, but replacing them is not difficult, moreover, they have a small price.

Pneumatic tools are used mainly in production and in small workshops. It belongs to the professional equipment.

Criteria for choosing a stapler for home and professional activities

Staplers for construction works are conventionally divided into household, semi-professional and professional models. The difference between them lies in the greatly expanded functionality of the latter: the presence of various settings, several operating modes, as well as a large operational resource. This leads to the fact that the price of a professional tool far exceeds the cost of domestic. Professional devices can be used in professional activities, for home use - it is expensive.

Home Products often made of plastic. They have a small working resource. Professional devices are the most reliable. They are made of metal (ordinary or stainless steel). Plastic in them only lining handles, softening the impact.

Semi-professional equipment occupies an intermediate place in terms of quality as well as price. Products from this category are a good choice for domestic use. They have a wide range of functionalities that allow them to perform an extended range of work at home.

The general criteria for choosing construction staplers are:

- possibility of disassembling the tool body;

- sizes of fasteners used;

- handle location (the closer it is to the body, the more convenient it is to work);

- the ability to perform power control of the breakdown mechanism;

- the presence of a double blow (important when working with solid materials).

Each model of staplers is designed only for a certain type and size of fasteners: nails, studs or staples. It is necessary to take into account this factor, as it shows the scope of the tool.

It is better to choose modifications so that they are suitable for fastening materials of different thickness: for wall paneling, film, insulation, plywood, and others.

Mechanical staplers are the most affordable option to use at home. Models equipped with a twisted spring, are the cheapest. Opportunities mechanics enough for many operations. It is recommended that a mechanical furniture type stapler (and indeed any) have folding design. This will facilitate maintenance with repair.

If you want to perform a relatively large amount of work at home,It is recommended to use more expensive and functional power tools - it will save time and effort. When autonomy is important, suitable battery or mechanical models. As for the models on batteries, it is required to prefer modifications with high-capacity batteries that can quickly charge. Well, when the equipment contains spare batteries.

Before you buy a stapler, you must also consider the availability of functions that ensure the safety of work with the tool.

Browse popular models in different categories

Construction staplers are produced by well-known manufacturers of construction tools, for example:

- EINHELL;

- SPARKY;

- Bosch;

- METABO;

- STURM;

- NOVUS;

- Intertool.

Product rating of these brands for many years is very high. Among manufacturing countries, the best quality staple guns are produced in Germany and Japan. When asked to “advise which stapler to choose for domestic or professional use,” you can confidently point to the products of the listed companies of the relevant category.

STURM ET4516

The model according to customer reviews in 2017 ranks first in popularity rating. among budget options. Like all products from STURM, the tool is distinguished by high-quality assembly, as well as component parts. The driving force is the energy of electric current. The model is connected to a stationary network with a voltage of 220 V. This power tool works with staples and nails, but small sizes (6-10 mm and 8-14 mm, respectively). For home use, STURM ET4516 is a good option.

- low price (about 1200 rubles);

- the possibility of using different types of fasteners;

- build quality;

- ease of maintenance and operation;

- sufficient rate of fire (20 shots per minute).

- it is possible to use only small sizes of staples with nails, which significantly limits the area of use of the tool;

- some inconvenience associated with the presence of the power cord, limiting the freedom of action;

- to work away from the mains need an extension cord;

- greater weight compared with similar devices (1.25 kg).

Bosch PTK 3.6 Li (0603968120)

Bosch PTK 3.6 Li (0603968120) - this German-made staple gun, refers to battery models. High quality provides reliability, durability of the tool.The model can only work with brackets of size 11.4x (4-10) mm. The Bosch PTK 3.6 Li (0603968120) stapler has a high rate of fire, which makes it possible to increase labor efficiency in its use. The modification is equipped with a 3.6 V battery with a capacity of 1.3 Ah. In terms of security, the tool is superior to network analogues.

- high rate of fire (30 shots per minute);

- quality and reliability (2 years warranty);

- charger included;

- light weight (0.8 kg);

- store availability (for 100 brackets);

- can work in humid conditions, as well as in explosive;

- sufficiently capacious battery.

- only small staples can be used;

- you need to monitor the battery charging, timely recharging it;

- the price exceeds the cost of electrical network analogs (about 4,000 rubles).

Intertool RT-0104

Among mechanical models Intertool RT-0104 is popular with consumers. The stapler with cassette magazine has a robust, simple design. It is universal, allowing the use of studs (pins), nails, staples (maximum width of 11.3 mm) length, respectively: 8-16mm, 8-16 mm, 6-14 mm. It can be used during household construction and repair work, as well as the assembly of furniture. The metal case contributes to the strength, durability of the mechanism.The presence of rubber pads on the handle increases the usability of the Intertool RT-0104.

- low weight (0.88 kg);

- function of adjustment of force of blow;

- ease of operation and maintenance;

- simple design;

- the possibility of using different fasteners;

- low price (about 750 rubles).

- the small size of the fasteners, because of which the area of use of the device is limited;

- Working with a stapler requires a lot of time and effort compared to the use of electric and pneumatic models.

To get a stapler, for example, for furniture, served for a long time, you must use branded consumables. It is necessary to regularly clean the used device from pollution, and to lubricate the mechanical models. At the choice of products it is mainly required to make a start from area of their future application. For everyday life suitable mechanical or electrical modifications stapling guns. Professional devices can be purchased when large amounts of work are to be done, especially for hard materials.

/rating_off.png)