The choice of router for home

Manual mill is not only the most popular, but also the most indispensable tool among the masters. The possibilities of this unit sometimes seem limitless, since it is used in almost all areas of the production of wood, plastic, metal and composite products. From this article you will learn what types of milling machines are, and how to choose this universal tool.

Purpose and capabilities of the router

A manual milling machine (RFM) or a milling machine is an apparatus that allows the processing of various products using a milling tool rotating at high speeds. The latter is a nozzle with two or more cutting edges. Due to the large number of types of cutters, the wizard has the opportunity to produce figured and finishing machining of the ends and corners of the product, as well as to perform a selection of grooves, various recesses and holes.

To use a milling machine, it is possible for the following operations.

- Door installation. Before you install the door, it is necessary to insert a lock into it. Before the advent of the router, simple tools were used to install the doors — a hammer and a chisel. With their help, the groove of the required depth was gradually hollowed out. But the use of the router for these purposes significantly simplified the whole process of cutting and reduced the time for its implementation several times. In addition, the router is convenient to use for landing door canopies.

- Figured processing of the end part of the product. To make the edges of the product from an array, for example, a wooden table top, have a more attractive appearance, milling with curly nozzles is performed.

- Figured processing of parts of kitchen facades from the array (racks, crossbars and panels).

- Sampling and spindle milling for the subsequent connection of wooden parts among themselves. For grooves and spikes using different cutters.

- Production of stationary milling mini-machine. The unit intended for installation in a table is screwed vertically (from below) or horizontally, to a table specially made for this purpose. This joinery machine allows the processing of small, short and very long parts in a single pass.

- Making a mini desktop- machine. In this case, a small table, similar in size to a stationary one, is assembled, after which, as in the previous version, a hand mill is screwed under the table. A mini desktop machine is also used for milling small parts that cannot be clamped with clamps.

- To remove edge overhangs after processing the ends of parts from chipboard. Usually for the edge of PVC and trimming it at a certain angle using a special edge milling cutter.

- For wood carving. Various patterns on wooden parts, as well as on products from MDF can be cut on the patterns previously printed on them or on patterns.

Of course, woodcarving with a hand-held power tool cannot be compared with the thread for the same material that a 3d router (meaning CNC router) performs. Thanks to the computer control of the machine, it is possible to achieve, at times, astounding results in volumetric wood carving.

A laser mill, or rather an engraver, is not capable of such a thread. With it, you can cut only blanks for souvenirs, make accessories from thin materials, burn any images on a wooden surface, and then at a depth limited by the laser focus.

- For chipboard. In this case, the router is used not only for machining the ends of the part, for example, after cutting it with an electric jigsaw, but also for rounding the corners of the product, milling the groove for the T-shaped PVC edge, for milling various recesses for mortise furniture handles.

- Artificial stone processing (kitchen sinks, worktops, etc.).

Types of hand mills

Manual milling machines are divided into several types, depending on their purpose.

Submersible and fixed

Top submersible RPM - These are the most versatile and frequently used units.With their help, you can make facing of parts, chamfering, select “quarters”, cut grooves, expand holes, cut out patterns and perform many other operations.

The vertical milling cutter (submersible) has spring-loaded upright guides, along which the engine moves up and down with a milling tool fixed in the collet. Also on the unit provides a stop that controls the depth of immersion tool in the material.

The presence of the stop many times simplifies the work with the apparatus and makes it possible to delve into the part to a certain depth without turning it off.

Stationary mill has a different design. Its engine is rigidly attached to the base body of the unit. To change the milling depth, turn off the machine, unscrew the elements fixing the engine, and after that raise or lower the drive.

You should know that the cutter at the router always stands for the plane of the lower part of the base, so beginners may have problems with this unit. For example, if it is necessary to make a closed groove in a piece of wood, then an inexperienced master will have to lower the unit to the milling site with rotating at full speedtool. At best, the device will lead to the side and the workpiece will be spoiled.

Edging

The main tasks for which the edge milling cutter (trimmer) is intended are the following:

- rounding the edges of the part;

- giving the edges of complex profiles;

- chamfering;

- milling of decorative grooves around the perimeter of the part, near the edge;

- PVC trimming;

- trimming protruding beyond the edges of the veneer parts;

- milling recesses under the loop.

Also, this unit can work on a copier, creating different ornaments on a wooden surface, or cut a drawing along the lines drawn.

At first glance, the edging (miter) milling cutter is similar to the classic vertical unit, only its slightly trimmed version. But in fact, the device has its undeniable advantages:

- maneuverability and ease of handling;

- small weight and compactness;

- small size of the sole, which allows the mill to work in a limited space.

Thanks low drive power, from 450 to 720 W, it is easy to hold a mini milling cutter with one hand. This makes it possible to save time and do without fixing the part to the workbench with clamps (the part can be held with the other hand).

The face (edge) milling cutter can be driven either along a horizontal guide or as an emphasis, which is mounted on the base of the apparatus.

In addition, edge milling machines began to appear on the market. with removable base. In such units, the housing with the drive is a module that can be mounted on different types of bases. For example, by changing the base, the unit can turn from an edge into a normal submersible (vertical) router. The following photo shows a double-base milling cutter.

Also on sale are universal edging RPMs having adjustable base. Due to the multifunctionality of the latter, it is possible to produce milling not only vertically, but also at any angle within 90 °.

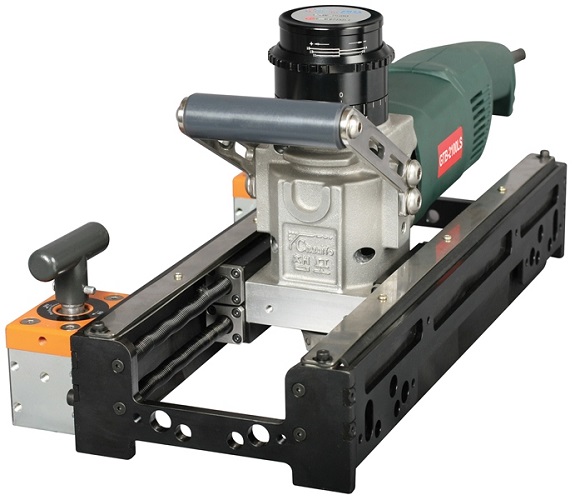

Edge-loop

This type of router is used in the professional field. for loops and locks without the use of additional tools.

A special platform mounted on an edge looping mill allows all operations to be carried out with maximum precision, and the high speed of the cutter turns provides a clean machining of the groove.

Lamella

Lamella frezer, he's keyway,in appearance it is very similar to a regular grinder with a special device attached to it. As a cutting tool in this unit are used disk cutterswhich for safety of the master are completely closed by a casing. With the help of cutters, grooves of a certain size are cut in the blank, after which glue is poured into them and lamellas are inserted. Next, you need to tighten the workpiece clamps and wait for the complete drying of the adhesive.

In addition, the unit can cut a groove not only in different planes, but also at the right angle due to the existing height and angle controls.

Also on the machine, you can quickly adjust the depth of the groove using turret stop. When the machine is fed forward, the cutter comes out of the bottom of the fixture and cuts into the material to a certain depth. It is precisely when the required milling depth is reached that the limiter prevents the disk from excessively deepening.

Basically, keyboard milling cutter is used by professionals. This specialized tool allows you to significantly save time, especially if you have to connect a large number of parts together.

Corner

This type of router is specifically designed. for processing artificial stone.

An angle mill is used to give the wall rim an inner radius, as shown in the following photos.

The router has special stop, which eliminates damage to the side walls of the product. The unit is very easy to manage, and the mating surfaces are milled easily and quickly. To obtain a better result of milling, first make a rough pass unit, and then - finish.

Rotary

This type of router is also called tiled. It is applied for drilling holes in ceramics. The diameter of the collet mounted on the unit is equal to 8 mm, and the spindle rotation speed of this small and light machine can reach up to 34000 rpm. At such a speed, the chances of damaging a tile are minimal, and the router cuts into it, like oil.

Rotary router is equipped speed controller and is able to maintain it at the right level even under load. A vacuum cleaner can be connected to this unit to remove fine dust.

Fillers

These duplex units are noticeably different from the universal tool.designed for milling wooden surfaces, and are highly specialized devices.

Using filler dowel milling cutter, you can make in the details of furniture pairing holes for dowels (spikes). Further, round spikes are inserted into these holes, smeared with glue, and the parts are joined.

On both sides of the cutters, there are spring-loaded stops that facilitate the precise setting of the tool for drilling the next pair.

The movable upper platform of the base can be rotated within 90 degrees, which makes it possible to make angular connections of parts.

Also, the upper part of the base can be raised or lowered to accurately center the cutters relative to the end part of the workpiece.

The filler mill can be used to drill holes in the upper or lower plane (face) of the part. If the workpiece is long, you can use a special ruler template. On it there are notches, located at the same distance from each other. The upper platform of the base is inserted into these cuts, and the router can be moved to the same distance.

Rechargeable

Some of the above types of milling machines can be rechargeable.The following accumulator RFMs can be found on the market: direct (submersible) units, lamella apparatus and edge mills (the following photos are shown in the named sequence).

Some modifications of the battery RPM use for drywallto make holes of complex shape in it.

In favor of these devices, we can say the following:

- battery type milling cutters has a compact size and light weight;

- the tool is distinguished by its mobility (the movement of the master is not limited by the length of the cable);

- the unit can be used in places where there is no power supply.

Metal cutters

These units are specifically designed for metal work, namely for stripping after welding and chamfering. This hand tool is fixed on rails that have sufficient rigidity and can be used to process both “black” steel and stainless steel. In addition to steel, the mill can process carbon (carbon fiber) and non-ferrous metals.

RPM composite

Composite panels have long been used in construction for cladding buildings, in the manufacture of outdoor advertising, etc.For cutting panels of the composite, as well as milling grooves often use a disk mill.

For high-quality processing of the panel, it is laid and secured (clamps), a special guide rail. The tire must be longer than the workpiece to be processed. On the guide set the router on the composite and produce the desired operation.

RFP for concrete

These milling machines are used for removing various coatings in large areas. The concrete milling machine can be used for removing seamless floors, old plaster, dried glue residues, old paint on walls, etc. Also, this stripping unit is used for leveling and grinding concrete surfaces before applying protective coatings on them.

Thanks to the movable base plate of the unit, a smooth adjustment of the milling depth is achieved, which ensures reliable tool guidance.

These types of milling machines have a convenient D-handleequipped with shock absorption, which significantly reduces the harmful effects of vibration on the operator.

Stone

For milling and grinding stone, such as granite or marble,use the router on the stone (kantofrezer). On the lower part of it, there are rollers for better movement of the unit on the plane of the workpiece.

The shaft with the cutting tool is lowered by means of a knob located at the top. Also all kantofruzery are completed with flexible hoses for the supply water cooling on the milling cutter.

A large number of cutters for this machine allows you to polish the concave, convex and rectangular edges of the workpiece with high quality, to cut the profile of any shape on the stone ends.

Criteria for choosing a tool

Before you choose a hand mill, you should be familiar with the basic and additional parameters of the units that affect the quality of work and their performance. The main parameters of RFM include drive power, spindle speed and milling depth.

Power

This parameter directly affects the capabilities of the RPM and depends on the engine power installed in it. The more power a drive can develop, the larger the diameter of the cutter can be installed on the unit. Also, devices with a power reserve are less exposed to overloads, overheating, and can operate for a longer time than low-powered machines.

You should know that powerful units have a large mass and large dimensions.Moreover, the price for them cannot be called affordable.

So, by this criterion, the manual milling cutters can be divided into:

- lungs - have a mass of from 2 to 3 kg and have a capacity of up to 750 W;

- medium - mass 3-5 kg, power from 750 to 1500 W;

- heavy - weight 5-6 kg, and in some cases more, power from 1500 to 2300 watts.

First of all, at the stage of choosing the unit, you need to analyze what work and with what intensity you are going to carry out this tool. If you need it for home, for single and short-term works, then you should not buy a heavy and powerful machine. But for the treatment of solid wood is still better to buy a device more powerful.

Experts advise to purchase milling cutters of the middle category with a capacity of up to 1500 W: it will be more than enough for home use of the tool and quite enough for professional use.

Rotational speed

You should know that the spindle speed depends on processing quality. The higher the speed, the better the result will be. At the same time, low spindle revolutions are also often used, for example, when milling plastic, which begins to melt at a high speed of rotation of the tool. For precise milling operations, low revs are also used.

Most RPMs operate with a tool rotation frequency ranging from 20 to 30 thousand rpm. But some cars can develop a smaller (up to 10 thousand) or more (up to 35 thousand) rev / min. Speed when processing parts should be selected taking into account the diameter of the cutter. The smaller the diameter of the cutting tool, the speed should be higher, and vice versa.

In addition, not only the size of the cutter, but also the depth of processing and the hardness of the material affect the speed. Therefore, the router should be with speed adjustment. Speed adjustment can be stepped or smooth. For the home workshop it does not play a big role. The main thing that the regulator was present on the instrument and was in good condition.

Recommendations for the correct setting of the spindle speeds can be found in the passport to the unit.

It is also desirable that the router has turnaround option at the same level under load.

Milling depth

This parameter affects not only the weight and power of the unit, but also its cost. Therefore, you should choose a submersible mill with such a maximum milling depth that will be sufficient to perform certain technological tasks.

Basically, the depth of immersion of the instrument in the workpiece at 45-50 mm will be sufficient if the RPM is used in the manufacture of cabinet furniture or solid wood furniture.

The depth of the instrument is adjustable special emphasisnot allowing excessive groove. On budget models of devices, the limiter is oriented on a millimeter scale, which cannot be called accurate. On expensive milling machines often install electronic depth gauges. The electronic depth gauge can measure the immersion of the instrument with an accuracy of tenths of a millimeter.

Also, the unit must have a depth adjuster. revolving type. It looks like a cylinder with steps of different heights. Due to the different height of the depth limiters, it is possible to carry out a gradual immersion of the cutter in the workpiece, turning the regulator after each pass.

Sole

The support platform of the unit is often referred to as sole. It is one of the most important elements of the whole structure. The support platform can be made by stamping or casting. Of course, cast playground will have the most correct geometry.

If you want to buy a household milling cutter, the cast or stamped pad does not matter. Applying RFM at home, special accuracy is not required, whereas in the professional sphere, the disturbed geometry of the site can lead to the fact that the entire batch of parts will become unsuitable for further use.

Rigging

On the availability of additional equipment depends on the functionality of the tool and its cost. Therefore, the choice of the router should be accompanied by a careful check of what kind of equipment the unit is completed with, and what quality it is.

When buying, you should ask whether it is possible to use additional equipment from other manufacturers on a specific router.

Additional equipment can include the following elements:

- parallel stop - Included in the package of almost all RPM;

- copy sleeve - allows milling according to a template;

- compass - with its help radial milling is performed.

If you buy universal router, it is necessary to check the presence and condition of the regulated base.

Extra options

Various additional functions that belong to one or another aggregate,designed to increase the reliability of the unit.

- Smooth start. This option will be useful for owners of powerful milling machines. Smooth start eliminates jerk when the engine starts, thereby reducing the likelihood of its failure. Also, the lack of jerk reduces the likelihood of damage to the workpiece when starting the engine.

- Protection against accidental starting. Any router should have an additional button, without pressing which (even if the start trigger is retracted) the unit will not start. Also, this button should fix the trigger, if you need to fix the router under the table.

- Spindle lock implemented as a button located near the spindle. When you click on it, the motor shaft locks, which significantly simplifies the unscrewing and twisting of the cutter clamped in the collet.

- Overload protection. This protection is not installed on all units. It works at the moment when the temperature on the windings of the electric drive exceeds the critical value. In some RFM models, one can learn about engine overheating by flashing indicator on the tool body. In more expensive models of milling machines when the windings overheat, the protection module disconnects the electric drive from the power supply.

Almost all professional RPMs are equipped with overload protection, since they are often subjected to heavy loads and work practically without interruption.

/rating_off.png)