How to choose a cutter on the characteristics

Manual cutter is a multifunctional, powerful tool for cutting various durable materials (for example, concrete, metal). The tool is driven by an internal combustion engine, thanks to which the equipment is completely autonomous. Cutting blanks, as a rule, is performed by a disk that rotates at a considerable speed. Some modifications equipped with a chain. In stores, you can purchase models for home use, professional or semi-professional activities. Consider the existing types of power cutters to make the right choice.

Content

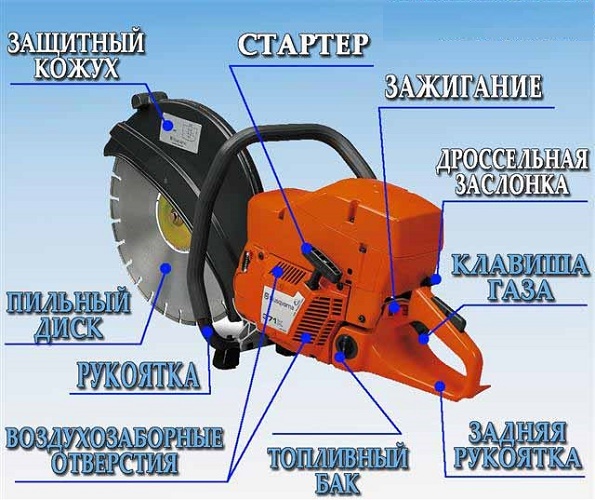

Power cutter design

The device of a petrol cutter is not difficult. Its main structural elements are:

- internal combustion engine (ICE);

- fuel tank;

- working nozzle (disk for cutting materials);

- front and rear handles;

- starter;

- housing;

- carburetor;

- gas button;

- air cleaning system consisting of filters;

- ignition;

- protective casing;

- throttle valve.

The tool is mainly equipped two-stroke motors. They run on fuel, which is a mixture of gasoline and oil in a certain proportional ratio. The transfer of rotational motion from the engine to the disk is due to the belt.

Multi-stage air purification prevents dust particles from getting inside the carburetor and cylinder. Water cooling system the cutting element, which is equipped with some models, also prevents the formation of dust. In addition, it prevents overheating of the disk, which slows down its wear and prolongs its service life. Water is supplied to the cutting zone from the tank.

Modifications weighing more than 15 kg, additionally equipped with carts to facilitate their transportation. In this part of them can be controlled remotely.Also, some models have legs, which allow for steady-state installation of the tool when cutting.

Working nozzles Benzorez can be 30-40 cm in diameter. Cutting discs can be diamond or abrasive. Working nozzles of the first type are made of steel, which is coated with diamond coating. The latter increases the resistance of the disc to wear.

Work a good cutting nozzle reduces the load on the engine.

Under the cutter welders means the device of another device that has a tank for fuel, pump, burner, oxygen and gasoline hoses. The gas cutter is used only to work with metal billets and metal structures.

Sphere of use of the tool

Benzorezy are intended not only for cutting of concrete or metal, with their help other solid materials are also sawn:

- a rock;

- asphalt;

- brick;

- slabs of composites;

- composite materials (for example, reinforced concrete pipes);

- cinder block and the like.

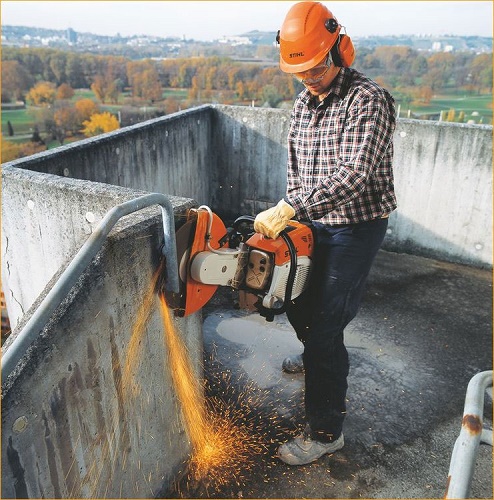

The tool is widely used by builders (including road workers) when conducting various repair and construction activities, eg:

- at dismantle of various designs;

- when cutting openings in walls or partitions;

- cutting reinforced concrete or metal pipes or beams;

- laying a border and paving slabs;

- during the breaking of partitions under the electric cable wiring;

- in the repair of railways and road pavement.

Similar operations with the help of technology and perform in everyday life.

In addition to the builders, such gasoline units are used by the staff of fire and rescue services.

The main advantage of cutters over electric angle grinders (grinders), various specialized types of saws is their independence from external power sources. Autonomy makes them popular among summer residents.

Types of power cutters for metal and concrete

Depending on the properties of the material being processed, gas cutters come in three categories:

- on metal;

- on concrete;

- universal models.

Power tool for cutting metal does not exceed 4200 watts. At the same time, the number of revolutions he has is lower than that of the equipment intended for work with concrete structures.

Equipment for cutting concrete produce more than 4.2 kW and with an average speed of rotation of the disc 4.7 thousand revolutions per minute.Such performance characteristics are required so that the working attachment does not get stuck in the cut monolith.

Universal modifications have great power and high speed, which allows you to saw with them using different materials.

On sale are also more specialized models of technology.

- Wall chaser (boroder) is a gas powered tool equipped with two parallel discs designed to create grooves in the walls, floor, ceiling for electrical wiring, pipes. Wall chasers are widely used by electricians and plumbers.

- Rail cutter - equipment used by railroad fitters when cutting rails. Rail cutters have special devices that allow them to be fixed on the rails, thereby increasing the depth of cut.

- Chain Cutter. A tool resembling a gasoline saw that makes it possible to cut both stone and metal thanks to the diamond chain.

- Chrome power tools (their cutting elements are partially covered with a chrome-coated casing visible in the dark), used by rescuers and emergency workers.

For chainsaws sold special nozzles.By installing them, you can use it as a chain cutter.

Benzo tools for processing different materials in their functionality is divided into the following types:

- household, calculated on the time of operation about an hour a day;

- semi-professional, having a working resource of about 8 hours a day;

- professional who can use more than 10 hours during the day.

Gasoline cutters are divided into models with a dry or wet method of processing material. The disc of the first type is air-cooled, therefore interruptions in work are periodically needed. For products with the possibility of carrying out wet cutting, a coolant (water) is used, which allows the device to be operated for a long time without rest.

The main and additional criteria for choosing a tool

When choosing a torch with an internal combustion engine that runs on gasoline, it is necessary to take into account its main technical and operational parameters:

- the power determining substantially productivity of the petroltool;

- maximum cutting depth (ranges from 97 to 260 mm);

- weight of the unit;

- functionality;

- launch time;

- built-in air cleaning system;

- the presence of systems that increase the safety of handling equipment, for example, a durable protective casing, the possibility of locking the disc if it gets stuck;

- ergonomic indicators, including the level of vibrations and convenience of the handle.

For many, important criteria that greatly influence the choice include price. Products from well-known brands (industry leaders) will cost more, but it has high quality components and assembly. Professional cutters from one company at a price surpass similar tools from the semi-professional and consumer categories.

The smaller the mass of the power tool and the weaker the vibrations from it during operation, the easier it will be to handle it. The handles should be comfortable so that your hands get tired more slowly.

When choosing a gasoline cutter according to its characteristics, you should focus primarily on the volume of regular future work and the type of material to be processed. For cutting, you will need a tool: for example, for floor slabs, concrete without reinforcement, metal, or asphalt, you need to decide in advance. So, the tool can handle iron up to 4.2 kW.To cut a monolith or reinforced concrete, it is better to use more powerful units.

Of additional selection criteria The following should be taken into account:

- convenience of carrying out maintenance activities;

- equipment manufacturer;

- cutting method;

- maintainability of the petroltool;

- basic equipment;

- the degree of purification of exhaust gases (the less toxic impurities, the better);

- warranty period.

Among manufacturers The best brands are:

- Husqvarna;

- Makita;

- Stihl;

- Echo.

For home use are good models from Stihl or Echo. Professionals suitable products from Husqvarna or Makit.

On the "dry" cut materials can be at insignificant amounts of work. Availability cooling systems makes gasoline tools more expensive and difficult both in maintenance and repair. But the "wet" method of cutting allows you to solve the problem with dust and increases productivity, which is important for continuous professional activity.

High performance, mobility and autonomy of work with compact dimensions make gas cutters popular among representatives of various professions, summer residents, and house craftsmen.The petrol tool allows them to cope with a wide range of tasks. At the same time, thanks to the relatively simple design, it is possible to independently eliminate many faults that occur during the workflow.

When choosing equipment that is suitable for its performance, one should give preference to models that are able to provide greater security for the user when using them. To ensure that the product lasts as long as possible, it is necessary to carry out timely, regular maintenance.

/rating_off.png)